A kind of mildew-resistant and antibacterial polyethylene pipe and preparation method thereof

A polyethylene pipe, anti-mildew and anti-bacterial technology, applied in the field of anti-mildew and anti-bacterial polyethylene pipes and its preparation, can solve the problems of poor barrier performance, decline in sanitation, mildew, etc., achieve good application prospects and economic benefits, improve Anti-mildew ability and the effect of increasing antibacterial ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

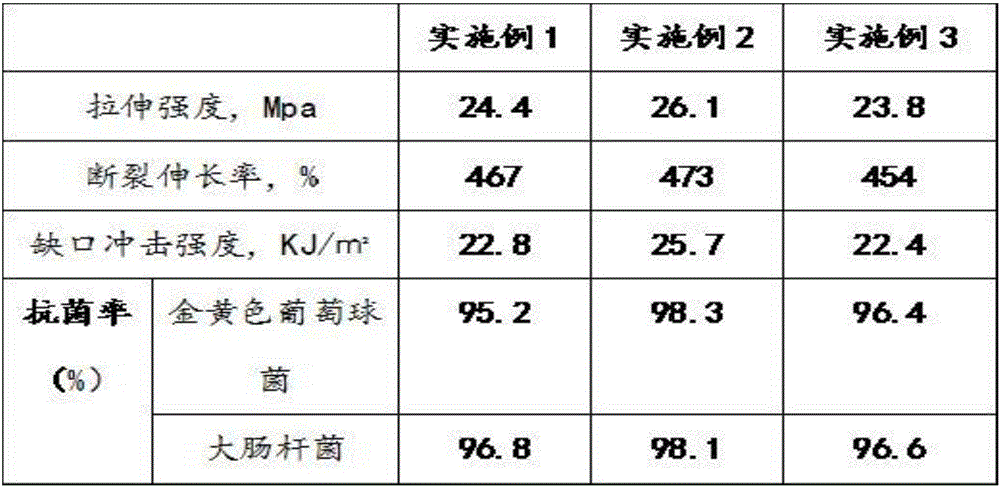

Examples

Embodiment 1

[0017] A mildew-proof and antibacterial polyethylene pipe, prepared from the following raw materials in parts by weight (kg): polyethylene resin 170, ethyl acetyl monoglyceride 12, zinc stearate 4, polyperfluoroethylene propylene 10, polyphosphoric acid Ammonium 5, hypochlorous acid 7, chlorinated polyethylene 5, graphite 6, silane coupling agent 7, triethyltin chloride 3, nano silver 10, activated carbon 4, antioxidant 10108, polyolefin resin 20, 2- Chloropropionylaniline 3, auxiliary agent 10; Said auxiliary agent is made of the raw material of following parts by weight (kg): nanometer calcium carbonate 15, polyethylene wax 5, mica powder 4, sodium fluoride 2, nano silicon dioxide 4 , dibutyl hydroxytoluene 3, copper oxide powder 7, m-aminopropionanilide 2, epoxy soybean oil 7, methylcyclohexane 10, aluminate coupling agent 6, polyoxyethylene fatty acid ester 3; preparation The method is: weigh the above-mentioned nano-calcium carbonate, mica powder, sodium fluoride, and nan...

Embodiment 2

[0024] A mildew-resistant and antibacterial polyethylene pipe, prepared from the following raw materials in parts by weight (kg): polyethylene resin 175, ethyl acetyl monoglyceride 13, zinc stearate 5, polyperfluoroethylene propylene 12.5, polyphosphoric acid Ammonium 6.5, hypochlorous acid 8, chlorinated polyethylene 5.5, graphite 6.5, silane coupling agent 7.5, triethyltin chloride 4, nano silver 11, activated carbon 4.5, antioxidant 10109, polyolefin resin 25, 2- Chloropropionylaniline 4, auxiliary agent 11; Described auxiliary agent is made of the raw material of following weight portion (kg): nano-calcium carbonate 17.5, polyethylene wax 5.5, mica powder 4.5, sodium fluoride 3, nano silicon dioxide 5 , dibutyl hydroxytoluene 4, copper oxide powder 7.5, m-amino propionamide 2.5, epoxy soybean oil 8, methylcyclohexane 11, aluminate coupling agent 7, polyoxyethylene fatty acid ester 4; preparation The method is: weigh the above-mentioned nano-calcium carbonate, mica powder, ...

Embodiment 3

[0027] A mildew-resistant and antibacterial polyethylene pipe, prepared from the following raw materials in parts by weight (kg): polyethylene resin 180, ethyl acetyl monoglyceride 14, zinc stearate 6, polyperfluoroethylene propylene 15, polyphosphoric acid Ammonium 8, hypochlorous acid 9, chlorinated polyethylene 6, graphite 7, silane coupling agent 8, triethyltin chloride 5, nano silver 12, activated carbon 5, antioxidant 101010, polyolefin resin 30, 2- Chloropropionyl aniline 5, auxiliary agent 12; Said auxiliary agent is made of the raw material of following parts by weight (kg): nano calcium carbonate 20, polyethylene wax 6, mica powder 5, sodium fluoride 4, nano silicon dioxide 6 , Dibutylhydroxytoluene 5, copper oxide powder 8, m-aminopropionanilide 3, epoxy soybean oil 9, methylcyclohexane 12, aluminate coupling agent 8, polyoxyethylene fatty acid ester 5; preparation The method is: weigh the above-mentioned nano-calcium carbonate, mica powder, sodium fluoride, and nan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com