Heat-treating process for hot-working die steel forgings

A technology of hot-working die steel and die steel, which is applied in the field of heavy industrial heat treatment, can solve the problems of high cost and limited performance improvement, and achieve the effect of improving performance, meeting performance requirements and increasing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

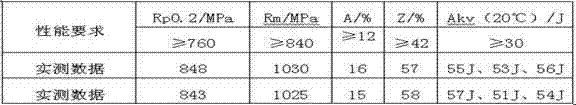

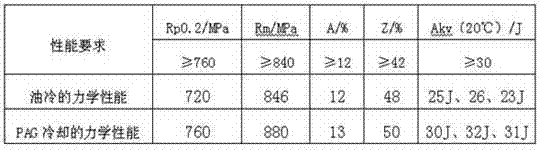

[0034] Example 1: 5CrNiMo die steel heat treatment

[0035] Increase the cooling rate, increase the depth of the hardened layer, so that the mechanical properties meet the customer's requirements, and the workpiece is subjected to the following heat treatment tests:

[0036] 1. Increase the spheroidizing annealing process before quenching: the forging is loaded in a furnace at ≤400°C, raised to 820°C at a speed of ≤60°C / h and kept for 8 hours, then cooled to 760°C at a rate of ≤15°C / h for 15 hours, and then Furnace cooling to 400°C at a rate of ≤10°C / h;

[0037] 2. Quenching: Furnace the forgings at ≤400°C at a rate of ≤60°C / h to 650°C, hold for 2 hours, then raise the temperature to 880°C at a rate of ≤80°C / h, and hold for 10 hours to make the workpiece fully quenched tempering;

[0038] 3. Cooling: raise the water temperature to 60°C, keep the workpiece at 860°C, and after 12 hours of heat preservation, take the workpiece out of the furnace with a crane, and then cool it ...

Embodiment 2

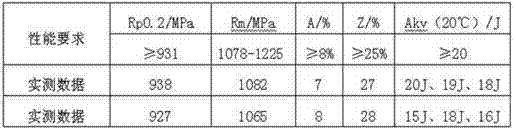

[0064] Example 2: Heat treatment of H13 die steel

[0065] Increase the cooling rate, increase the depth of the hardened layer, so that the mechanical performance requirements meet the customer's requirements, and the workpiece is subjected to the following heat treatment tests:

[0066] 1. Increase the spheroidizing annealing process before quenching: the forging is loaded in the furnace at ≤400°C, raised to 860°C at a speed of ≤60°C / h for 12 hours, cooled to 760°C at a rate of ≤30°C / h for 35 hours, and then press ≤30℃ / h speed furnace cooling to 240℃;

[0067] 2. Quenching: Furnace the forgings at ≤400°C, raise the temperature to 680°C at a rate of ≤60°C / h for 3 hours, then raise the temperature to 1050°C at a rate of ≤80°C / h, and hold for 16 hours to make the workpiece fully tempering;

[0068] 3. Cooling: Raise the water temperature to 40°C, take the workpiece out of the furnace with a crane, and then use air cooling for 2.5 minutes-water for 8 minutes-empty for 1 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com