Components of high-toughness ultrahigh-strength steel and preparation process of high-toughness ultrahigh-strength steel

A technology of ultra-high strength steel and preparation process, applied in the field of alloy steel, to achieve the effect of reducing the use cost and good plasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

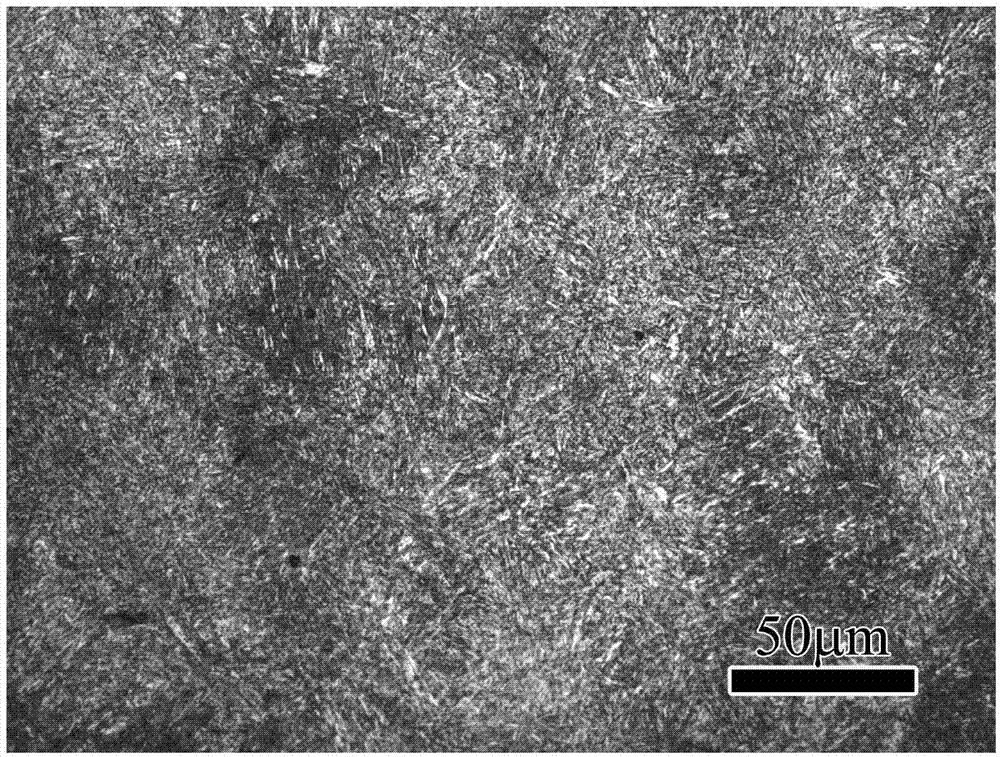

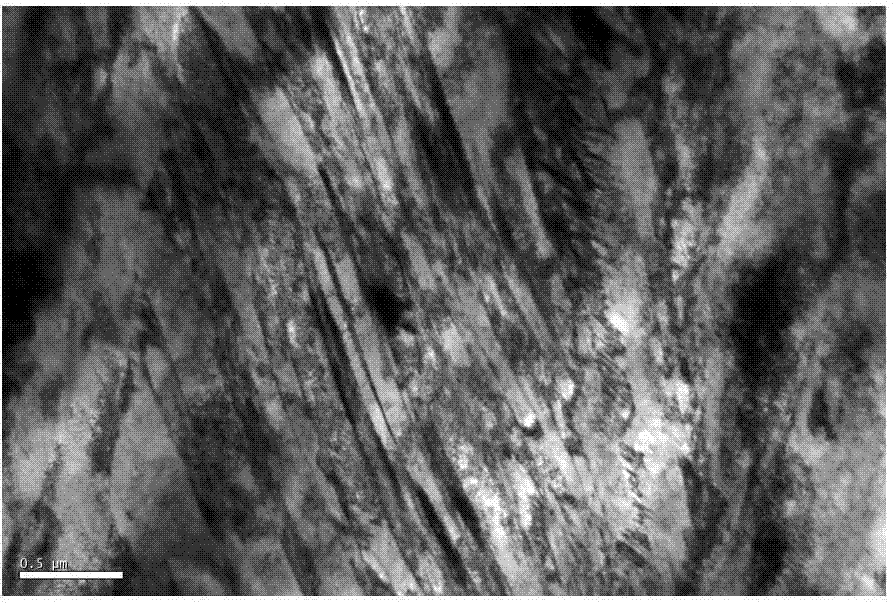

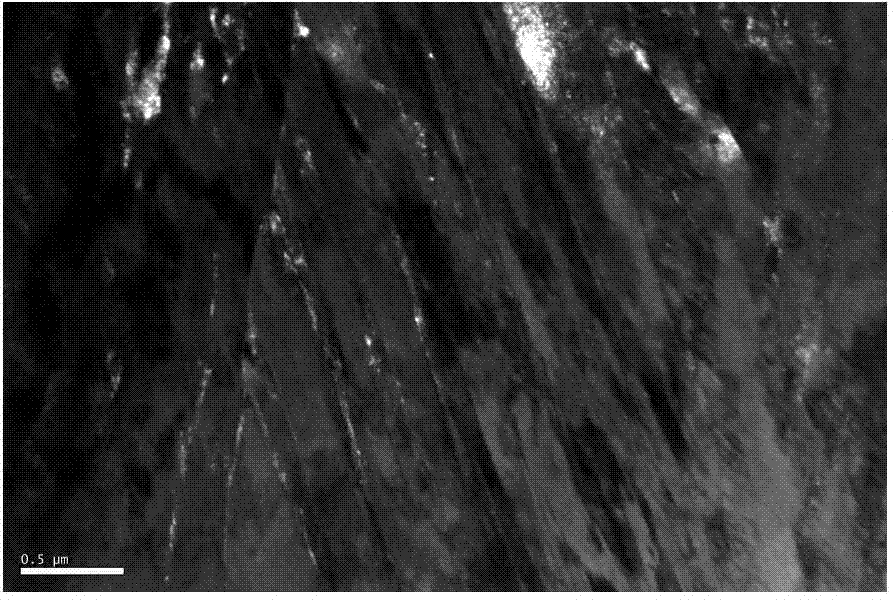

Image

Examples

Embodiment 1

[0026] The preparation process of a kind of high-toughness ultra-high strength steel of the present invention, concrete treatment process is as follows:

[0027] 1) Vacuum induction furnace melting method is used to control the content of alloying elements in steel, recorded in mass percentage: C: 0.26%, Si: 0.73%, Mn: 1.30%, Cr: 2.62%, Ni: 3.44%, W: 2.88% , Mo: 0.45%, V: 0.23%, P: 0.0045%, S: 0.0024%, O: 0.0016%, N: 0.001%, Cu: 0.034%, balance: Fe, and a steel ingot was obtained.

[0028] 2) For the steel ingot obtained by smelting, a forging process of three upsetting and three drawing is carried out. The specific steps are as follows: Process 1: Initial forging temperature is 1150°C, upsetting to half of the height, and then pulled to the original height; Process 2: Reheating temperature is 1080°C, upsetting to half the height, and then pulled to the original height; Process 3 : Return to the furnace at a heating temperature of 1050°C, upsetting to half the height, and the...

Embodiment 2

[0032] The preparation process of a kind of high-toughness ultra-high strength steel of the present invention, concrete treatment process is as follows:

[0033] 1) Vacuum induction furnace melting method is used to control the content of alloying elements in steel, recorded in mass percentage: C: 0.32, Si: 0.82, Mn: 0.72, Cr: 3.14, Ni: 3.36, W: 3.79, Mo: 0.66, V : 0.31, P: 0.0046, S: 0.0023, O: 0.0014, N: 0.001, Cu: 0.027, balance: Fe, and a steel ingot was obtained.

[0034] 2) For the steel ingot obtained by smelting, a forging process of three upsetting and three drawing is carried out. The specific steps are as follows: Process 1: Initial forging temperature is 1150°C, upsetting to half of the height, and then pulled to the original height; Process 2: Reheating temperature is 1080°C, upsetting to half the height, and then pulled to the original height; Process 3 : Return to the furnace at a heating temperature of 1050°C, upsetting to half the height, and then forging or ...

Embodiment 3

[0038] The preparation process of a kind of high-toughness ultra-high strength steel of the present invention, concrete treatment process is as follows:

[0039] 1) Vacuum induction furnace melting method is used to control the content of alloying elements in steel, recorded in mass percentage: C: 0.41, Si: 0.99, Mn: 0.74, Cr: 2.82, Ni: 3.31, W: 4.24, Mo: 0.42, V : 0.18, P: 0.0046, S: 0.0026, O: 0.0015, N: 0.001, Cu: 0.039, balance: Fe, and a steel ingot was obtained.

[0040] 2) For the steel ingot obtained by smelting, a forging process of three upsetting and three drawing is carried out. The specific steps are as follows: Process 1: Initial forging temperature is 1150°C, upsetting to half of the height, and then pulled to the original height; Process 2: Reheating temperature is 1080°C, upsetting to half the height, and then pulled to the original height; Process 3 : Return to the furnace at a heating temperature of 1050°C, upsetting to half the height, and then forging or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com