Method for controlling deformation of thin-walled aluminum alloy bracket with cavity structure during heat treatment

An aluminum alloy bracket, heat treatment deformation technology, applied in thin-walled cavity easily deformed aluminum alloy parts, thin-walled cavity structure aluminum alloy bracket heat treatment deformation control field, can solve the problem that cold calibration cannot be satisfied and the deformation amount of machining is large. , complex structure and other problems, to achieve the effect of simple structure, solving workpiece deformation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0030] The specific embodiment is carried out according to the following process steps:

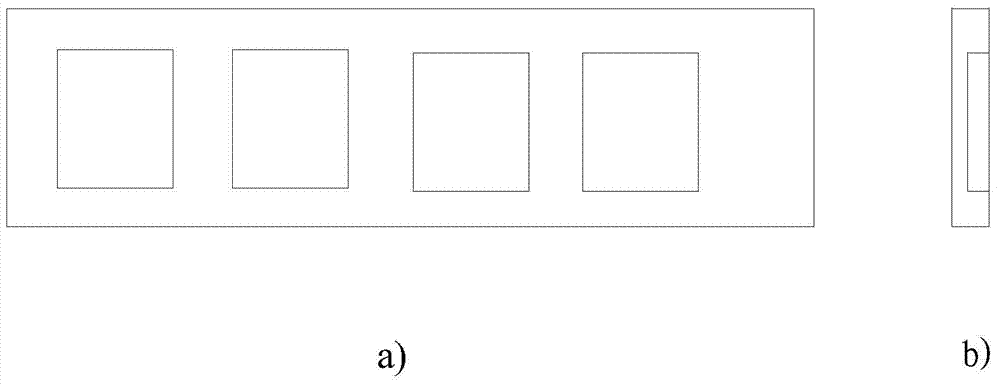

[0031] The first step is to determine the way of entering the furnace: the workpiece is placed vertically in the long direction;

[0032] The second step is to determine the heating and heat preservation process parameters: the workpiece is heated to 280 ° C, and heat preservation is 30 minutes;

[0033] The third step, rapid water quenching: less than 15s transfer time, the workpiece quickly enters the water, the water temperature is 30°C; the workpiece stays in the water for 5 minutes;

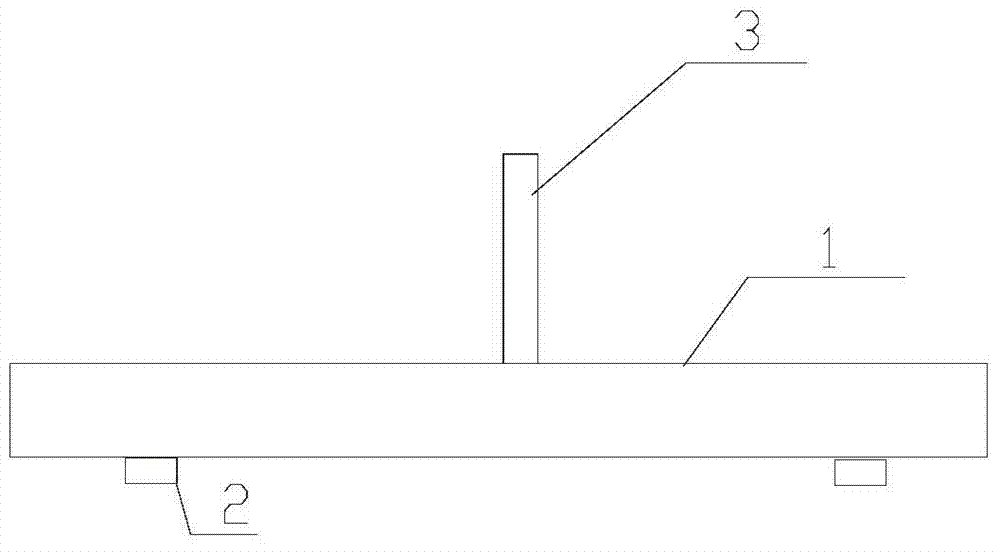

[0034] The fourth step is to correct the shape in sections: as attached figure 2 As shown, the workpiece 1 is placed on the shape-calibrating platform, and the shape-calibrating cushion block 2 is set under it. The hydraulic machine 3 is used for the shape-calibration. First, the shape is calibrated at 1 / 4 of the long direction of the workpiece, and then the 3 / 4 of the long direction of the workpiece ...

Embodiment 2

[0037] The specific embodiment is carried out according to the following process steps:

[0038] The first step is to determine the way of entering the furnace: the workpiece is placed vertically in the long direction;

[0039] The second step is to determine the heating and heat preservation process parameters: the workpiece is heated to 290°C and held for 20 minutes;

[0040] The third step, water quenching: less than 15s transfer time, the workpiece enters the water quickly, the water temperature is 30°C, and the workpiece stays in the water for 10 minutes;

[0041] The fourth step, segmented shape correction: use the hydraulic press 1 to calibrate the shape of the 1 / 4 part of the long direction of the workpiece, 2 then calibrate the shape of the 3 / 4 part of the long direction of the workpiece, and finally calibrate the shape of the 1 / 2 part of the long direction of the workpiece;

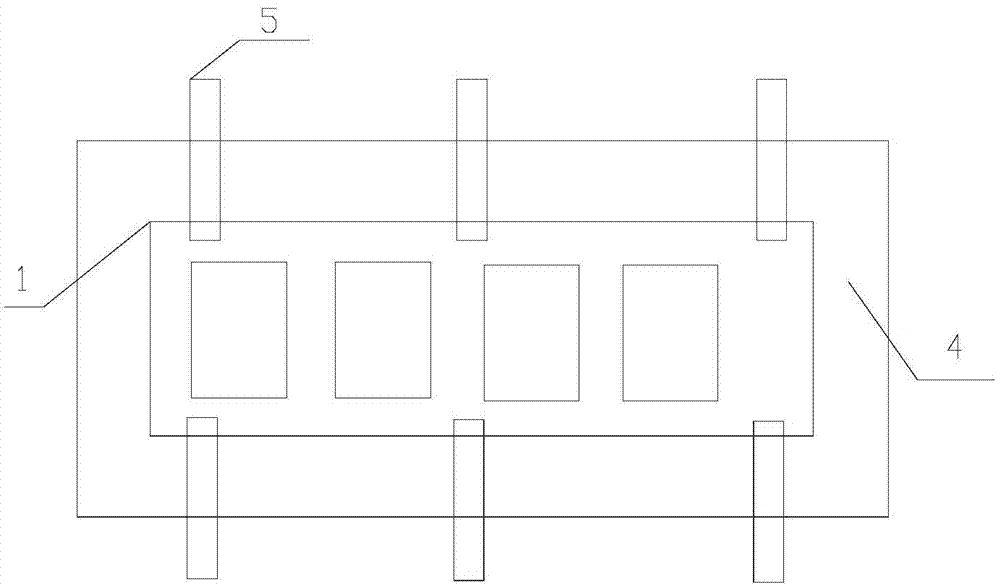

[0042] The fifth step, tooling and shape: calibrate the finished workpiece and immediately ...

Embodiment 3

[0044] The specific embodiment is carried out according to the following process steps:

[0045] The first step is to determine the way of entering the furnace: the workpiece is placed vertically in the long direction;

[0046] The second step is to determine the heating and heat preservation process parameters: the workpiece is heated to 285°C and held for 25 minutes;

[0047] The third step, water quenching: less than 15s transfer time, the workpiece enters the water quickly, the water temperature is 25°C, and the workpiece stays in the water for 5 minutes;

[0048] The fourth step, segmented shape correction: use the hydraulic press 1 to calibrate the shape of the 1 / 4 part of the long direction of the workpiece, 2 then calibrate the shape of the 3 / 4 part of the long direction of the workpiece, and finally calibrate the shape of the 1 / 2 part of the long direction of the workpiece;

[0049] The fifth step, tooling and shape: calibrate the workpiece and immediately install th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com