Truss-restrained type buckling-restrained brace

A technology of anti-buckling braces and trusses, which is applied in the direction of earthquake resistance and building components, can solve the problems of difficulty in the overall transportation of buckling-resistant braces, affect architectural effects, and multiple building spaces, so as to facilitate architectural modeling, reduce calculation length, The effect of aesthetic appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

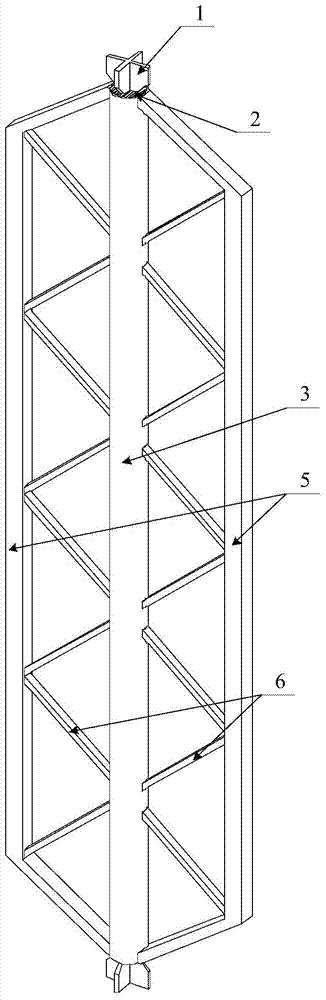

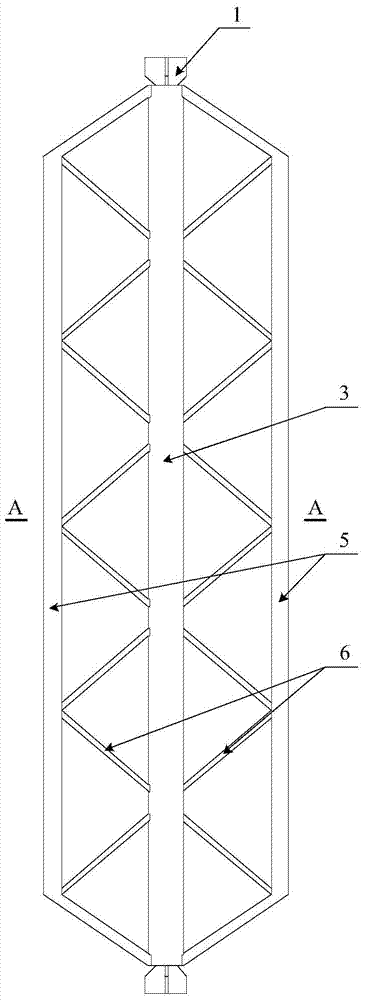

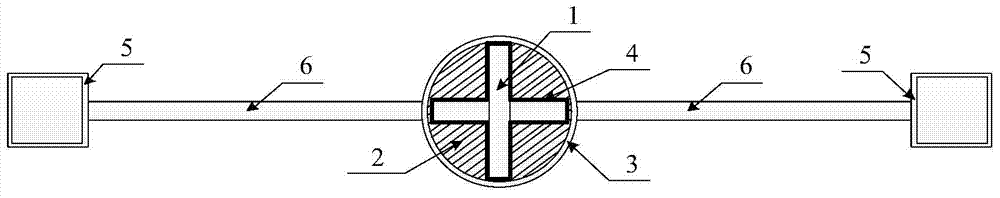

[0019] Attached below Figure 1~6 , detailing the implementation of this patent.

[0020] Such as Figure 1~5 As shown, a truss-restrained buckling-resistant bracing member includes the following components:

[0021] 1——cross core steel plate, including 1-1—narrow flat steel plate one; 1-2—narrow flat steel plate two; 1-3—wide flat steel plate;

[0022] 2 - filled with concrete;

[0023] 3—constrained steel pipe;

[0024] 4 - hard rubber;

[0025] 5—bent square steel pipe, including 5-1—short rectangular steel pipe 1; 5-2—short rectangular steel pipe 2; 5-3—long rectangular steel pipe;

[0026] 6——connect the square steel pipe.

[0027] Such as Figure 4 As shown, the length of the cross core steel plate 1 is greater than that of the restraint steel (3, and consists of two narrower flat steel plates 1-1, 1-2 and a wider flat steel plate 1-3 by welding; as shown in Figure 3 , paste hard rubber 4 on the surface of the area where the cross core steel plate 1 is wrapped by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com