Steel wire core modular heat insulation inner wall

A technology of steel wire clips and steel wires, which is applied in the direction of heat preservation, walls, building components, etc. It can solve the problems of difficult high-speed assembly, unsightly appearance, poor heat preservation, etc., and achieve the effect of beautiful appearance, light weight and good stress structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

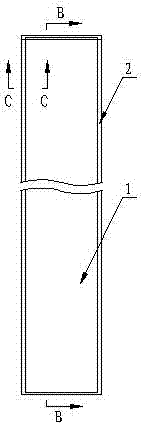

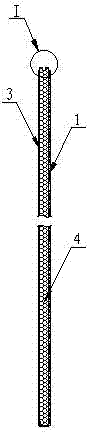

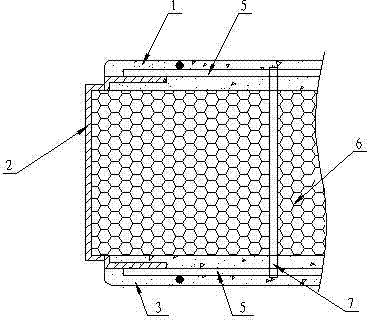

[0022] Such as figure 1 , figure 2 , image 3 As shown, a modular thermal insulation inner wall sandwiched by steel wire 5 includes an inner core 4, a wrapping 2 and a concrete layer. A core 4, said inner core 4 is located between the outer concrete layer 1 and the inner concrete layer 3.

[0023] Such as image 3 , Figure 4 As shown, the inner core 4 is composed of a core board 6 and a steel wire 5, and the core board 6 is made of thermal insulation material, such as rock wool, the main purpose of which is to improve the heat insulation performance of the wall, so that the heat inside and outside the wall The exchange is greatly reduced to save cooling and heating energy in the room. The steel wires 5 are sandwiched between the inner and outer sides of the core plate 6 and are connected to each other through the tie bars 7. The steel wires 5 on the inner and outer sides of the core plate 6 are poured into the inner concrete layer 3 and the outer concrete layer 1 respec...

Embodiment 2

[0027] Such as Figure 5 As shown, a modular thermal insulation interior wall sandwiched by steel wire 5 includes a core plate 6, steel wire 5, wrapping 2, inner concrete layer 3 and outer concrete layer 1, and its basic structure is the same as that of embodiment 1, except that In that: the steel wires 5 on the inner and outer sides of the core plate 6 are all poured into the inner concrete layer 3 and the outer concrete layer 1, the wrapping 2 is made of steel plates or section steel, and the two ends of the wrapping 2 are respectively embedded in the inner concrete layer 3 and the outer concrete layer 1. In the outer concrete layer 1, and connected with the steel wire 5 as a whole.

[0028] The upper or lower end of the wrapping 2 is provided with a protruding plug-in strip 9 or a guide rail, and a corresponding groove 8 or track is provided on the girder, or column, or the floor, so that the plug-in strip or guide rail of the thermal insulation inner wall can pass through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com