Spraying and maintaining device for concrete

A technology of spraying device and concrete, which is applied in the direction of construction, building structure, and building material processing, etc., which can solve the problems of reducing work efficiency, requiring manual operation, and high cost of curing fluid, so as to reduce maintenance costs, improve work efficiency, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

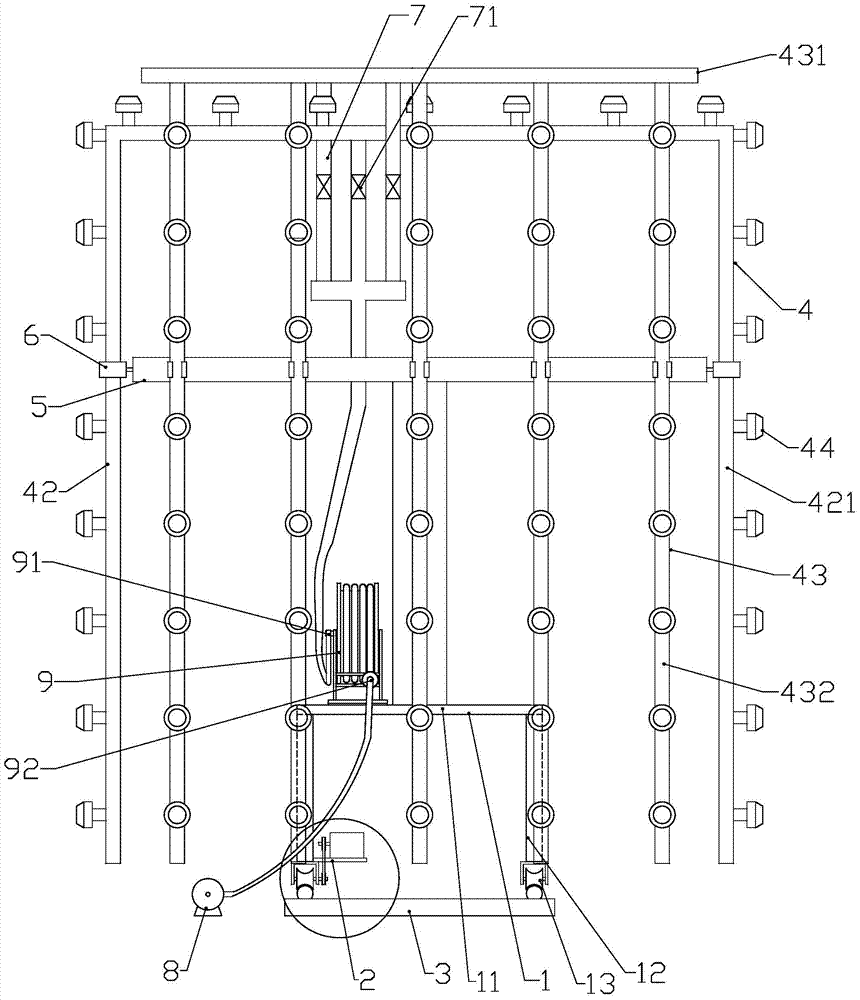

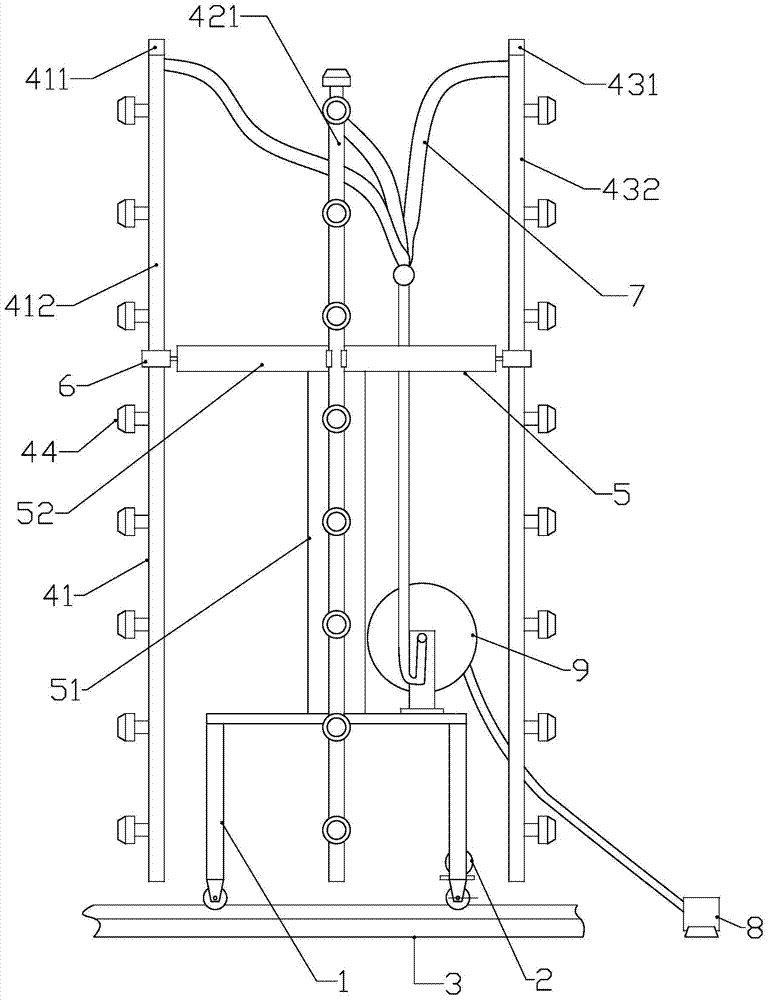

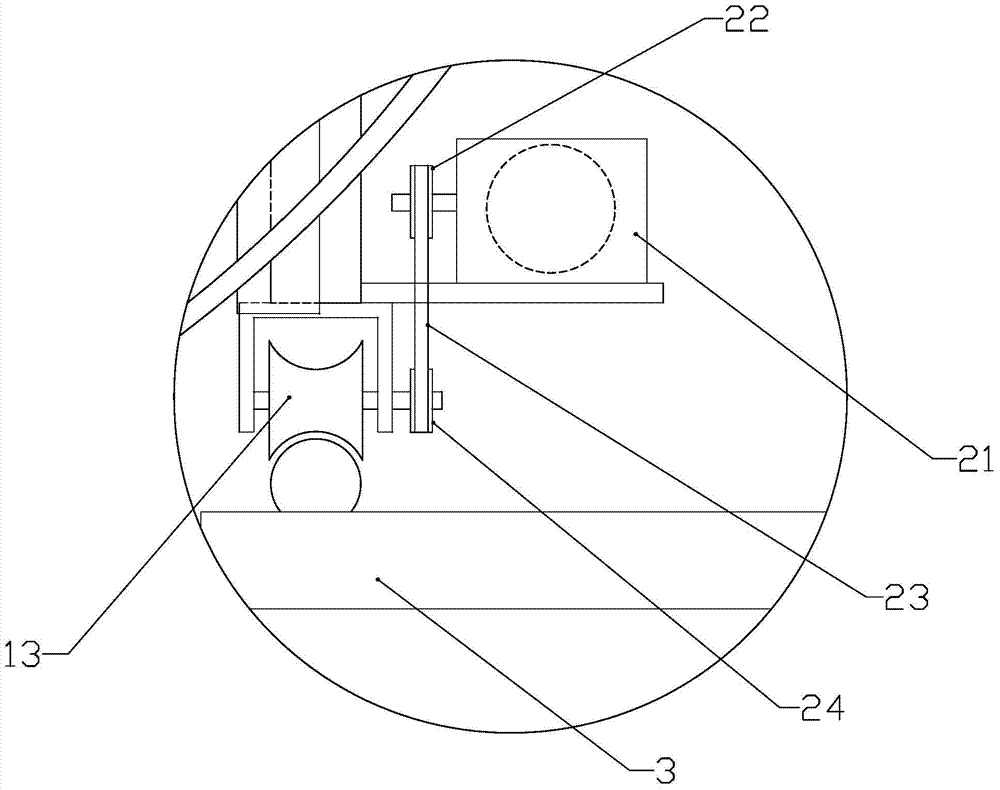

[0036] Refer to the attached figure 1 To attach image 3 The concrete spray curing device of the present invention will be described in detail below.

[0037] The concrete spray maintenance device of the present invention has a structure comprising a traveling trolley 1, a trolley driving mechanism 2, a trolley traveling track 3, a spraying device 4 and a supporting device 5;

[0038] The trolley walking track 3 is longitudinally arranged, the walking trolley 1 is located on the trolley walking track 3, and the walking trolley 1 is connected with the trolley driving mechanism 2;

[0039] The supporting device 5 is arranged on the upper part of the trolley 1, and the spraying device 4 is arranged on the supporting device 5;

[0040] The spraying device 4 includes a front spraying device 41, a middle spraying device 42 and a rear spraying device 43, and the front spraying device 41, the middle spraying device 42 and the rear spraying device 43 are respectively arranged at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com