Respective drive type multifunctional caliper

A multi-functional caliper technology, applied in borehole/well components, measurement, earthwork drilling and production, etc., can solve the problems of affecting measurement data, push arm can not be actively controlled, etc., and achieve high maneuverability and simple structure , the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

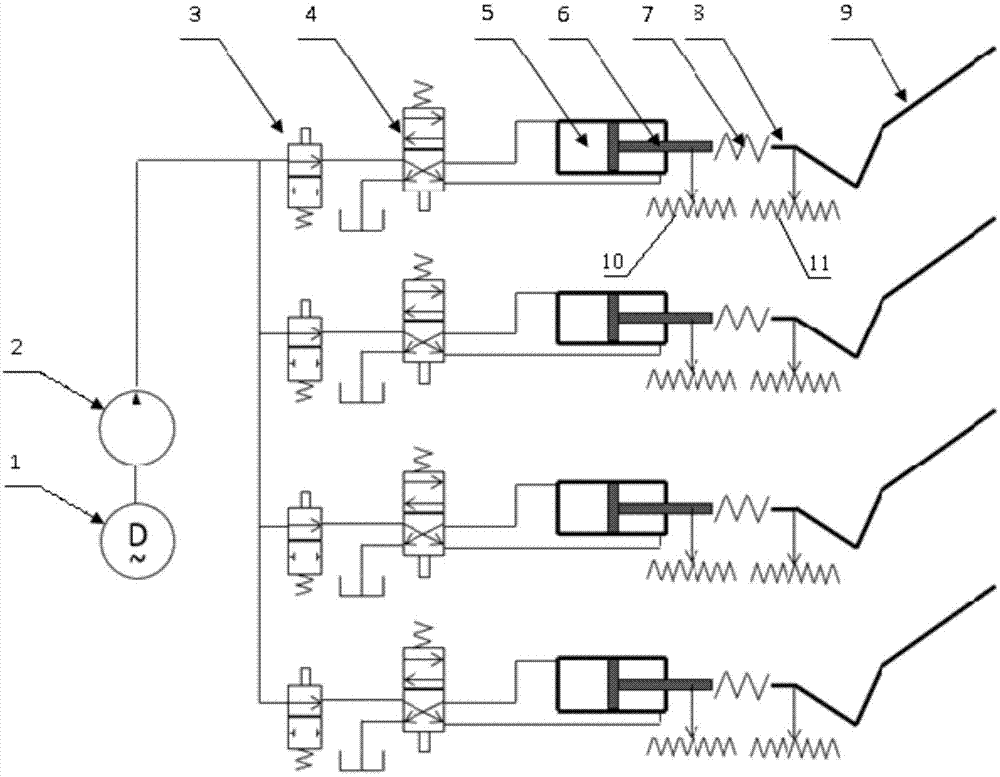

[0021] The split type multifunctional caliper of the present invention, such as figure 1 As shown, it includes a motor 1, a pump 2, a hydraulic oil circuit, a solenoid valve group, a hydraulic cylinder 5, a spring 7, a push rod 8 and a push arm 9; the motor 1 and the pump 2 are connected and driven by a coupling; the hydraulic oil circuit Including the main oil circuit and the branch oil circuit, the upstream end of the main oil circuit is provided with a pump 2, and the downstream end is provided with a plurality of branch oil circuits corresponding to the push arm 9 in parallel; the solenoid valve group and the hydraulic cylinder 5 with the piston 6 installed inside They are sequentially connected to form an actuator, which is respectively arranged on each branch oil circuit for controlling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com