A gas-assisted optional injector

An injector and air-assisted technology, which is applied in exhaust devices, machines/engines, noise reduction devices, etc., can solve the problems of reduced dosage, carbon black accumulation, blockage, etc., to prevent the formation of carbon black and high spray quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

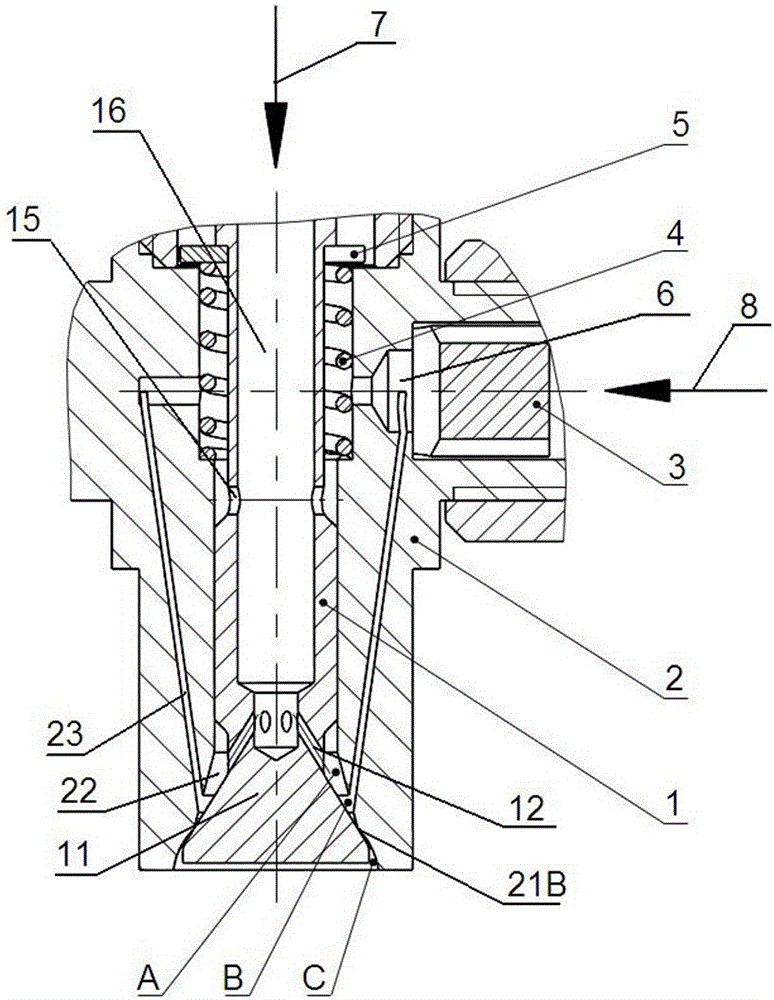

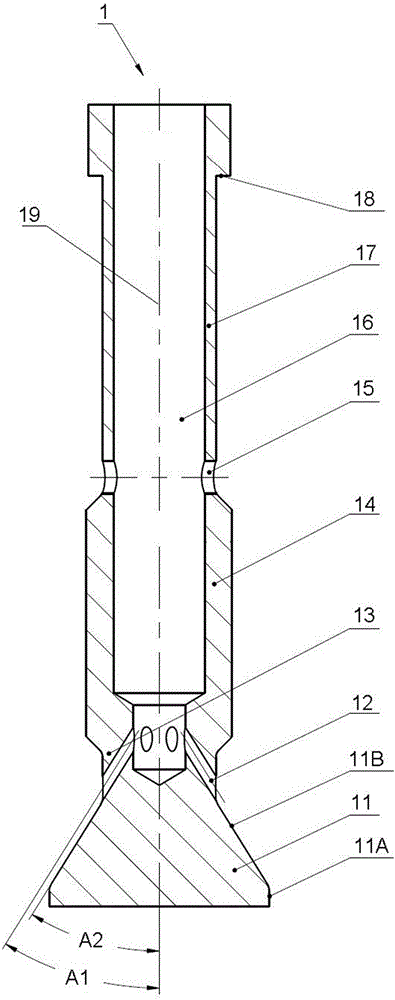

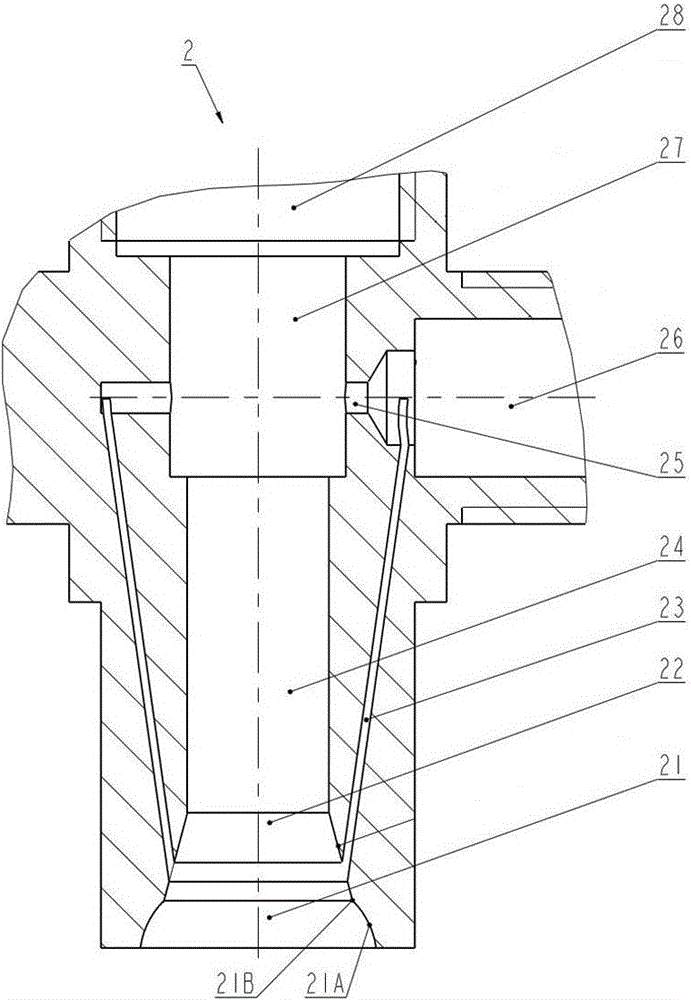

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

[0029] Such as figure 1 and Figure 5 As shown, a gas-assisted optional injector includes a valve core 1 and a valve seat 2 that can cooperate with each other and are arranged coaxially. The valve core 1 is preferably able to move axially in the valve seat 2. Of course, as in the CN 102182533 A patent, the injector can be set to a normally open state, and the valve core 1 remains stationary relative to the valve seat 2, which also belongs to the present invention scope of protection.

[0030] The mechanism for driving the valve core 1 to move axially relative to the valve seat 2 is a relatively mature prior art, such as using electromagnet on-off or spring force to automatically reset and the like.

[0031] The automatic reset by spring force is used as a specific embodiment below to describe the present invention in more...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com