Siphon type Adblue urea adding method and device

A filling device, siphon type technology, applied in the direction of muffler, exhaust device, exhaust treatment device, etc., can solve the problems of difficult design, decline in atomization quality, easy crystallization and clogging of nozzles, etc., and achieve improvement The effects of metering accuracy and atomization quality, reducing manufacturing difficulty and production cost, and reducing engine power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

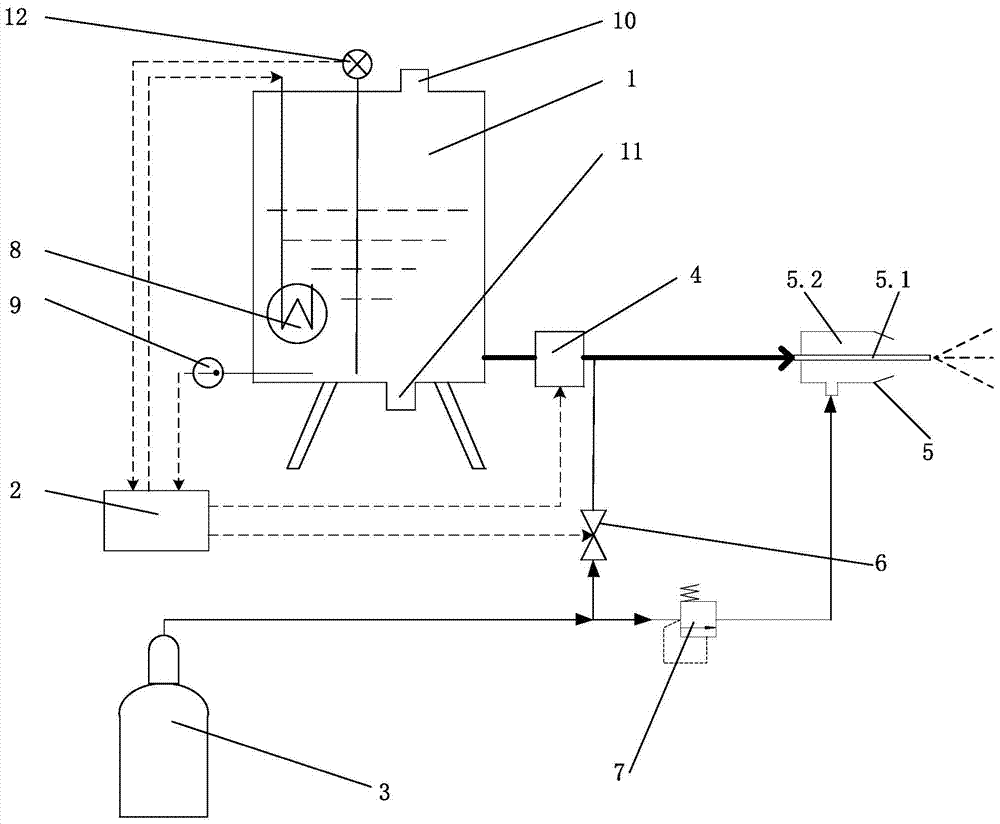

[0022] Such as figure 1 As shown, a kind of siphon type blue filling device designed by the present invention includes blue blue storage tank 1, control unit 2, compressed air source 3, metering solenoid valve 4 and siphon spray gun 5, and said blue blue storage tank 1 outputs End is connected with the blue input end of siphon spray gun 5 through metering electromagnetic valve 4, and the liquid level of described blue add storage tank 1 is higher than the liquid level of described siphon spray gun 5; Described compressed air source 3 and described siphon spray gun 5 The air input end is connected to each other, and a negative pressure is formed at the outlet of the siphon spray gun 5; the control unit 2 is connected to the metering solenoid valve 4 to control the opening frequency and opening degree of the metering solenoid valve 4.

[0023] As a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com