Axial plunger motor

An axial piston motor and plunger technology, which is applied in the field of axial piston motors, can solve the problem that the efficiency and reliability of the axial piston motor are greatly affected, the machining accuracy and shape and position tolerance of parts are required to be high, and the limitations Axial piston motor industry development and other issues, to achieve the effect of reducing the difficulty of assembly process, suitable for low speed characteristics, low vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

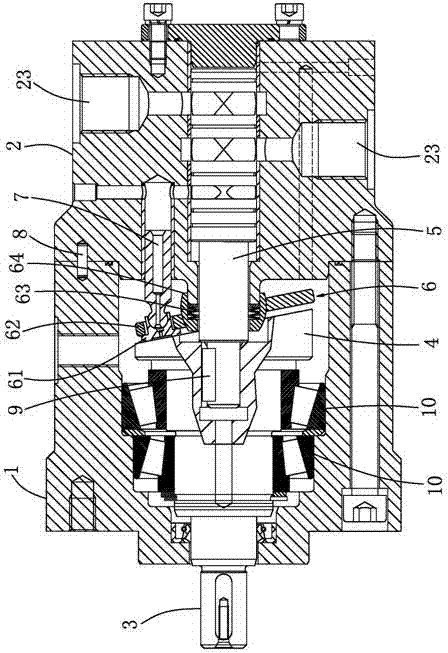

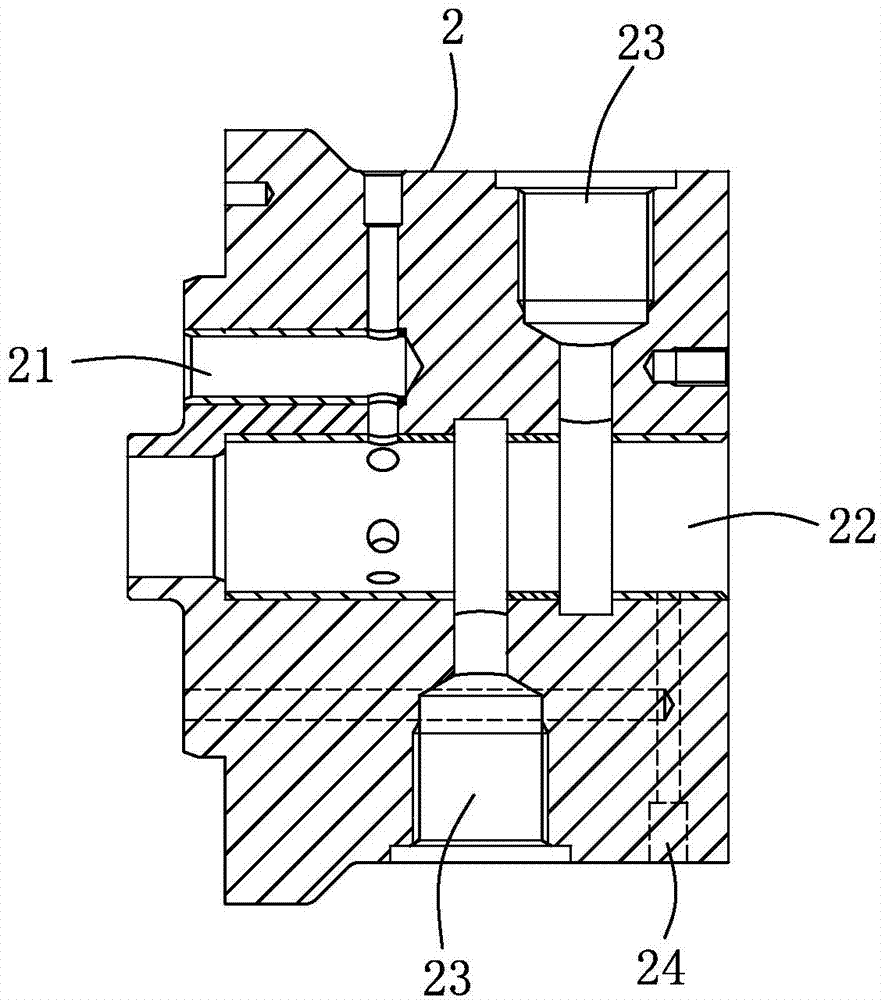

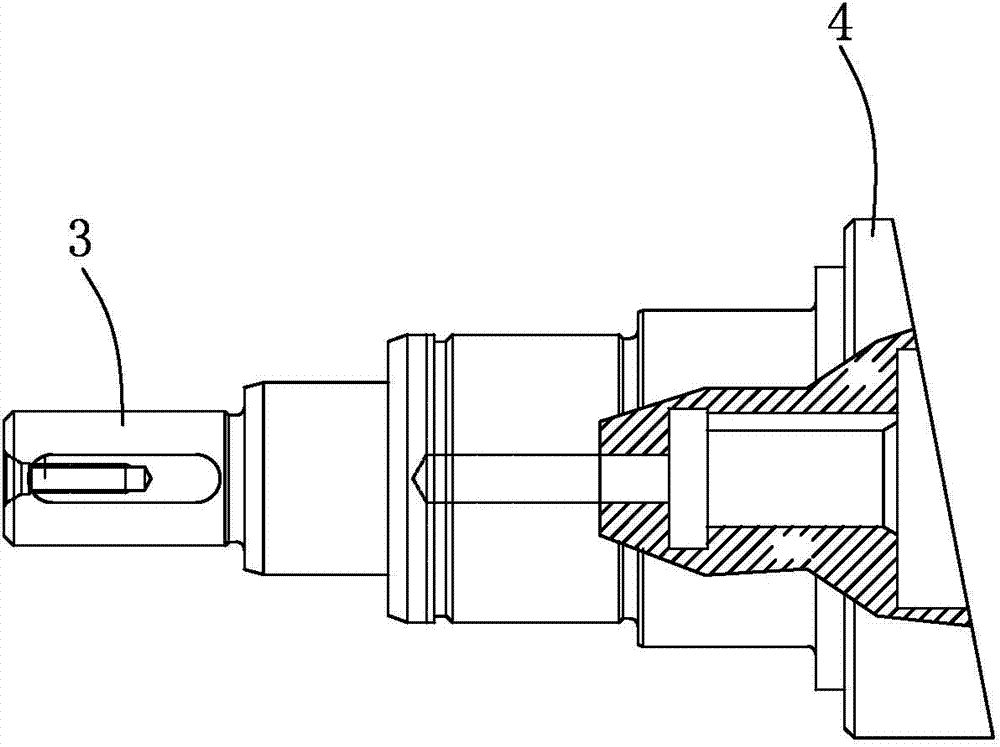

[0022] See Figure 1 to Figure 4 , an axial plunger motor, including a housing 1, a cylinder body 2, a transmission shaft 3, a swash plate 4, a flow distribution shaft 5, a shoe assembly 6 and a plunger 7, and the transmission shaft 3 and the swash plate 4 are connected as an integral structure , the housing 1 is fixedly connected to the cylinder body 2, the swash plate 4 is set on the housing 1, the distribution shaft 5 is set on the cylinder body 2, and the swash plate 4 and the distribution shaft 5 are fixedly connected, so that the swash plate 4 and the distribution shaft 5 can be synchronized Rotated, the cylinder body 2 is provided with several plunger holes 21 , the shoe assembly 6 is in contact with the slope of the swash plate 4 , the plunger 7 is connected with the shoe assembly 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com