Design method of automobile headlamp reflector

A technology of automobile headlights and design methods, which is applied in the field of headlights and can solve problems such as low light efficiency and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings of the description.

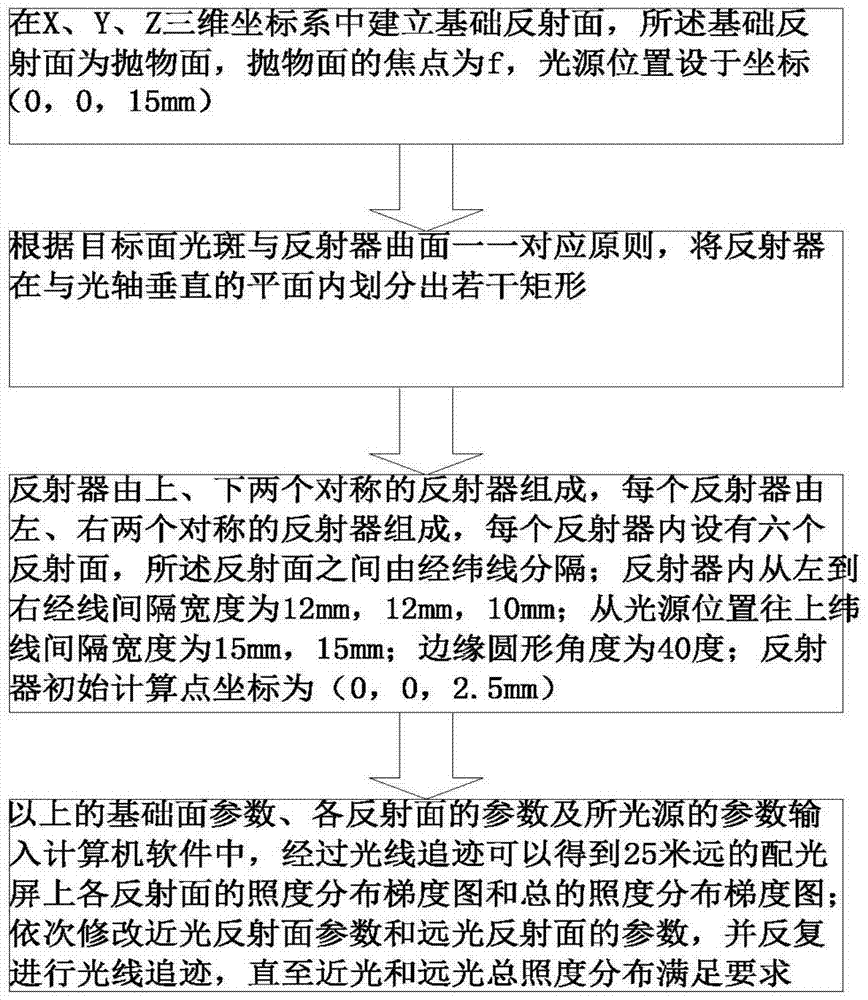

[0041] Such as figure 1 Shown, a kind of automobile headlight reflector design method, comprises the following steps:

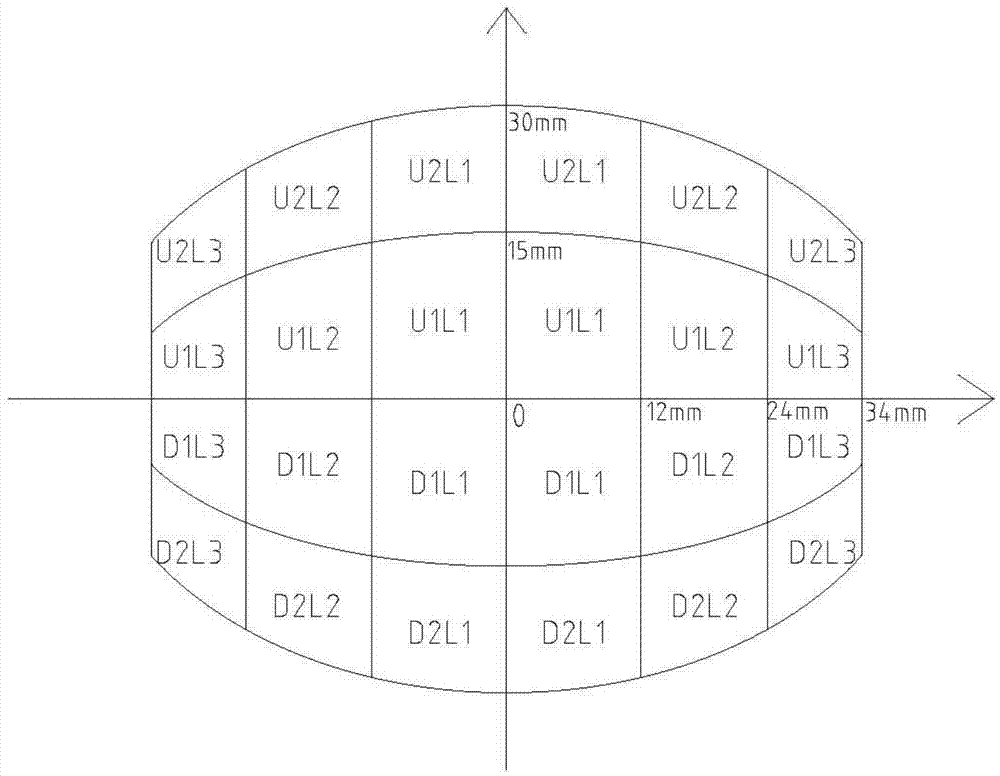

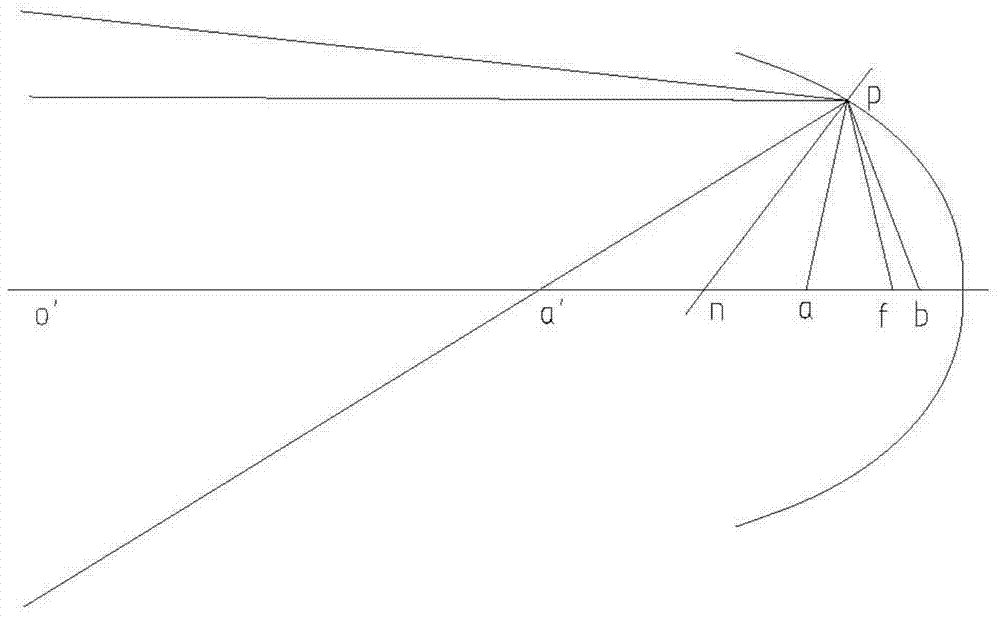

[0042] (1) The car light is a complete lighting system. In order to meet a certain illuminance value, the traditional vehicle uses a parabola as a reflector, and the filament is located near the focus of the parabola. The design of the free-form surface lamp basically adopts this principle; Such as image 3 As shown, the basic reflective surface is established in the X, Y, Z three-dimensional coordinate system. The basic reflective surface is a paraboloid, and the focus of the paraboloid is f. According to the principle of the paraboloid, since the light emitted from the focus is emitted in parallel through the paraboloid, The position of the light source is set at coordinates (0, 0, 15mm);

[0043](2) According to the light dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com