Firework inner cylinder assembly machine

A technology of fireworks barrels and assembly machines, which is applied in pyrotechnics, offensive equipment, weapon types, etc. It can solve problems such as endangering the lives of workers, flammability and explosion, etc., and achieves the effect of compact structure, solving safety problems, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

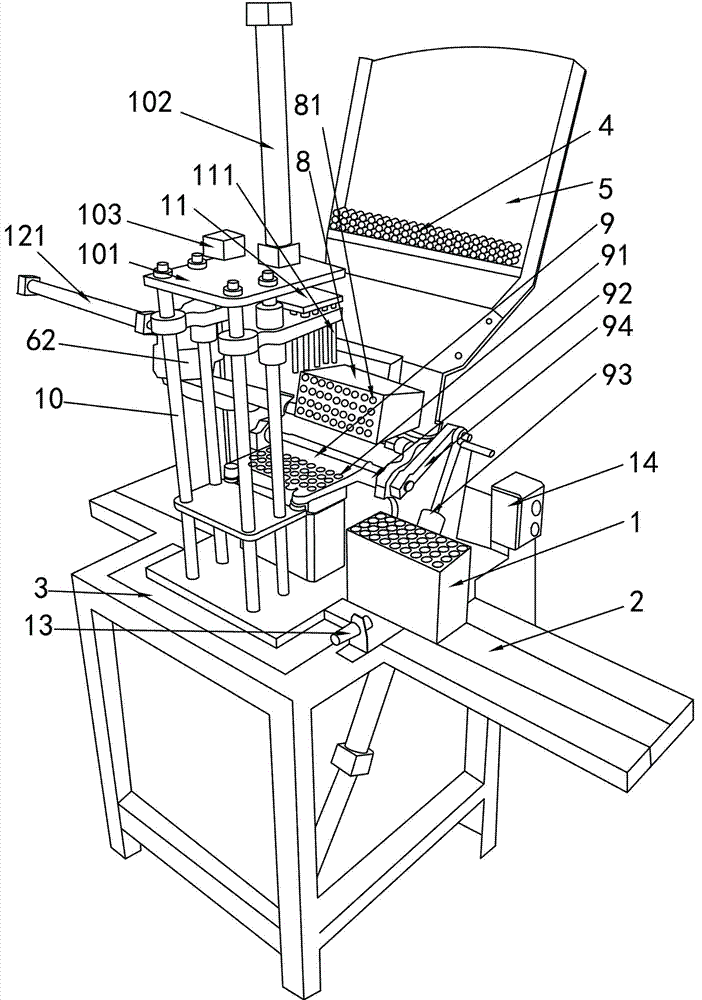

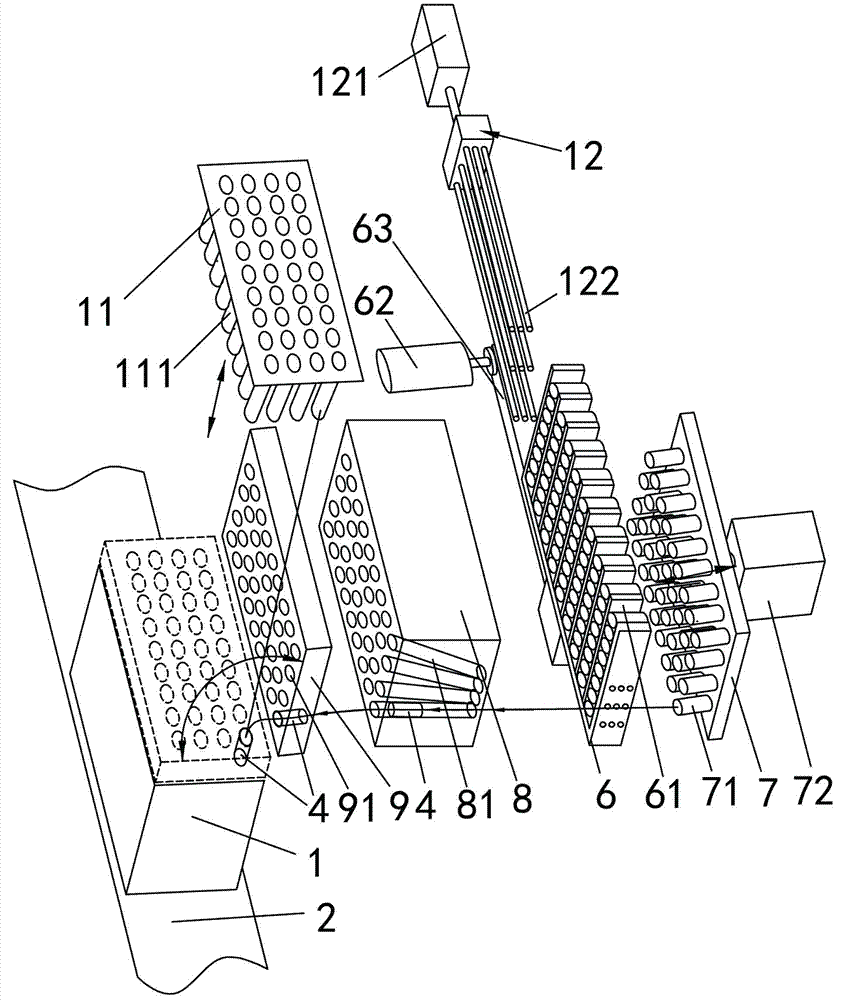

[0015] Such as figure 1 , 2 As shown in . and 3, the firecracker inner barrel assembly machine proposed by the present invention includes a conveyor belt structure 2 for transmitting the fireworks barrel 1 and a body 3 arranged on the conveyor belt structure 2. The body 3 is provided with a charging mechanism, and the entire gas-electric part All are controlled systematically by the PLC control system, and the PLC control system controls the charging mechanism to assemble the inner cylinder 4 into the described fireworks barrel 1 .

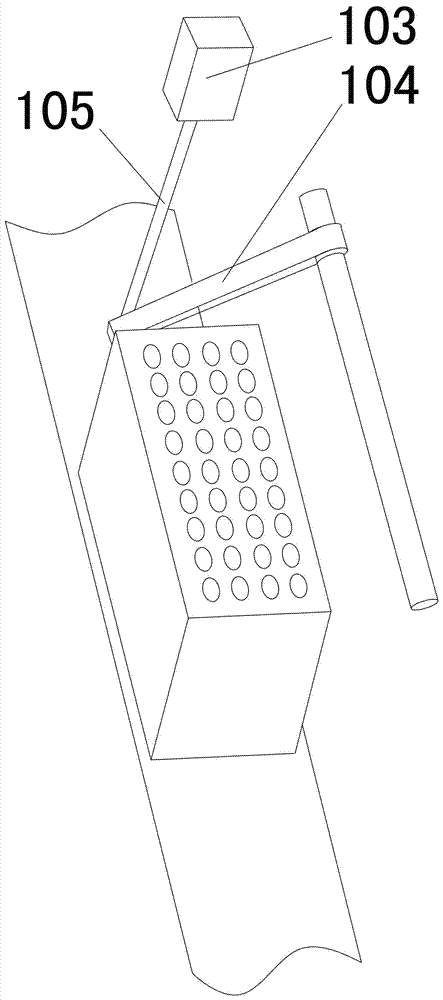

[0016] Wherein, the charging mechanism includes a feed hopper 5 vertically fixed on the machine body, the feed hopper 5 is slightly inclined, and the thickness of the inner chamber of the feed hopper is the same as the height of the inner cylinder 4, and the inner cylinder 4 is horizontally stacked on the feed hopper 5 inside; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com