Assembly and rectification method for collimator

A collimating light tube, calibrating technology, applied in measuring devices, testing optical performance, instruments, etc., can solve the problems of large randomness, long calibrating cycle, low calibrating accuracy, etc., to reduce non-parallelism, improve Accuracy of installation and calibration, overcoming the effect of strong randomness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Such as Figure 5 As shown, it is a layout diagram for realizing the measurement of the optical path in a preferred embodiment of the collimator installation method of the present invention, wherein, in order to realize the measurement of the wave aberration of the collimator, this embodiment adopts the interference The interferometer is placed at the focal plane of the collimator light pipe. The interferometer emits a standard spherical wave. The spherical wave is collimated by the light pipe to form a parallel beam and hits the plane mirror at the exit. The incoming light is reflected by the plane mirror. In the optical path of the tube, it is reflected by the primary mirror at the front end of the interferometer to perform interference imaging with the standard spherical wave, and the interferometer obtains the wave surface information, and then obtains the Zernike coefficient.

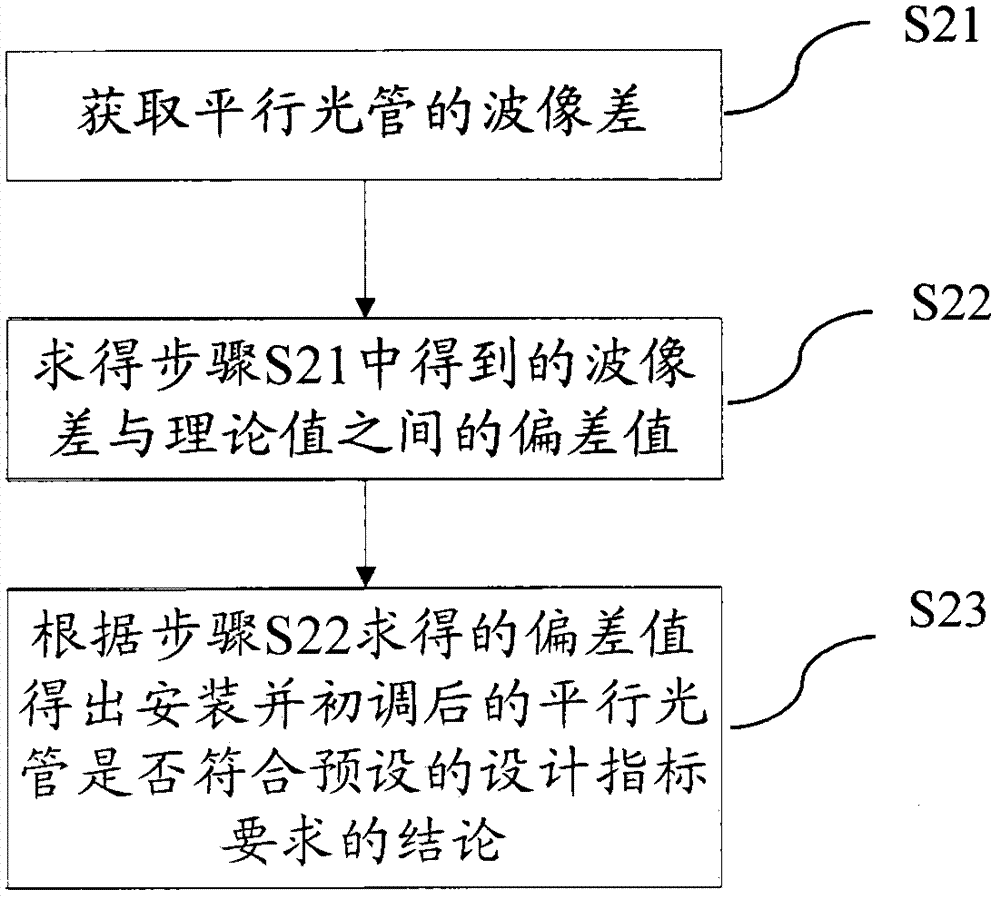

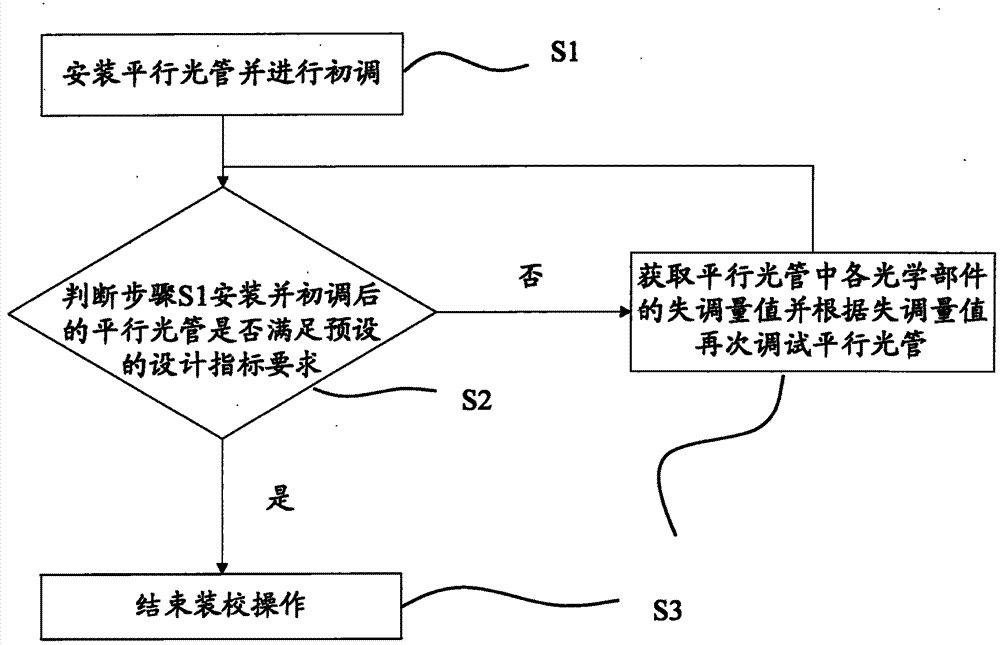

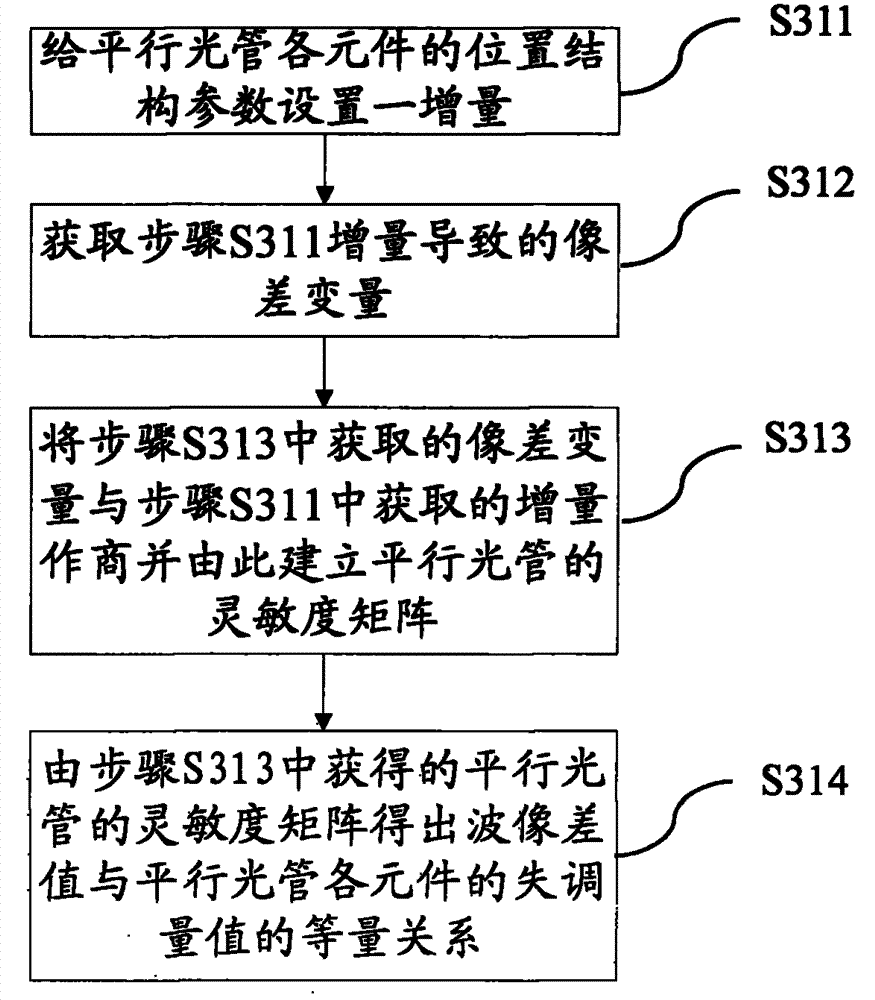

[0063] Such as Figure 6 As shown, it is the flow chart of collimator installation and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com