Method of dynamic monitoring of air leakage in clinker sensible heat recovery system for titanium dioxide production

A technology of dynamic monitoring and sensible heat recovery, which is applied in the direction of measurement devices, program control in sequence/logic controllers, instruments, etc., can solve the problems of reducing sensible heat recovery rate, property loss, energy waste, etc., and achieve recovery, The effect of improving accuracy and ensuring recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

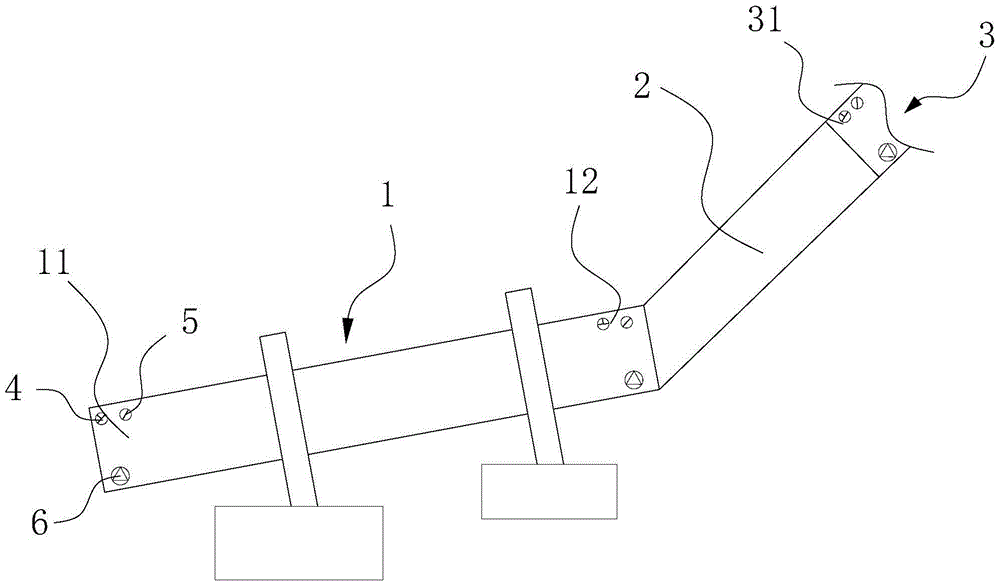

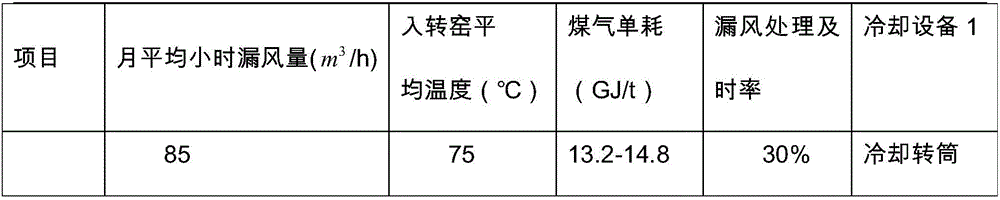

[0120] An enterprise produces a kind of rutile titanium dioxide with a designed production capacity of 40,000 tons. The original process parameters are shown in the following table:

[0121]

[0122] The method of dynamically monitoring the air leakage of the clinker sensible heat recovery system for titanium dioxide production is used to monitor the air leakage, and the specific implementation process of improving the sensible heat recovery rate of rutile titanium dioxide is as follows:

[0123] 1. Select and install cooling equipment outlet 12 and calcining rotary kiln inlet 31 air flow meter 4, thermocouple 5, pressure gauge 6

[0124] ① Select thermocouple 5 for low temperature, cooling equipment outlet 12 and calcining rotary kiln inlet 31

[0125]

[0126] ②Install thermocouple 5 and supporting temperature transmitter; install pressure gauge 6 and supporting pressure transmitter, install flow meter and supporting flow transmitter.

[0127] ③Connect the 4-20mA curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com