Wear test device and wear test method

A wear test and installation port technology, applied in the direction of testing wear resistance, weighing by removing certain components, etc., can solve problems such as many procedures for testing equipment, scrap rubber wheel B1, aging rubber layer, etc., to ensure effective The effect of stability and evaluation, low cost of use, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

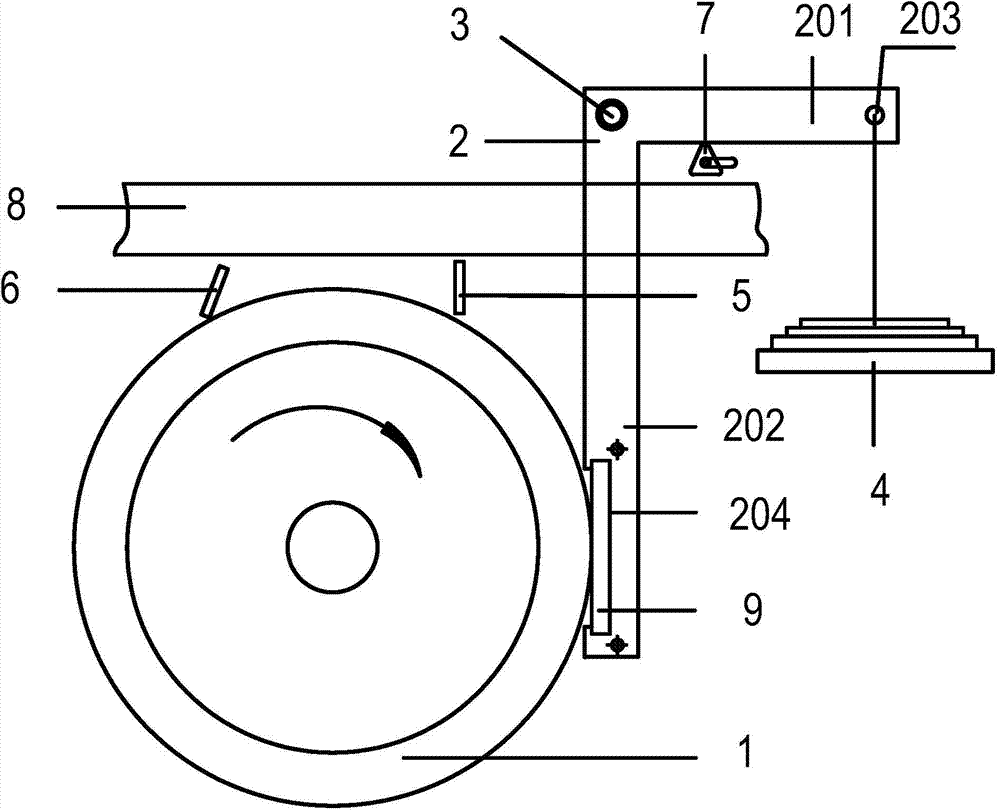

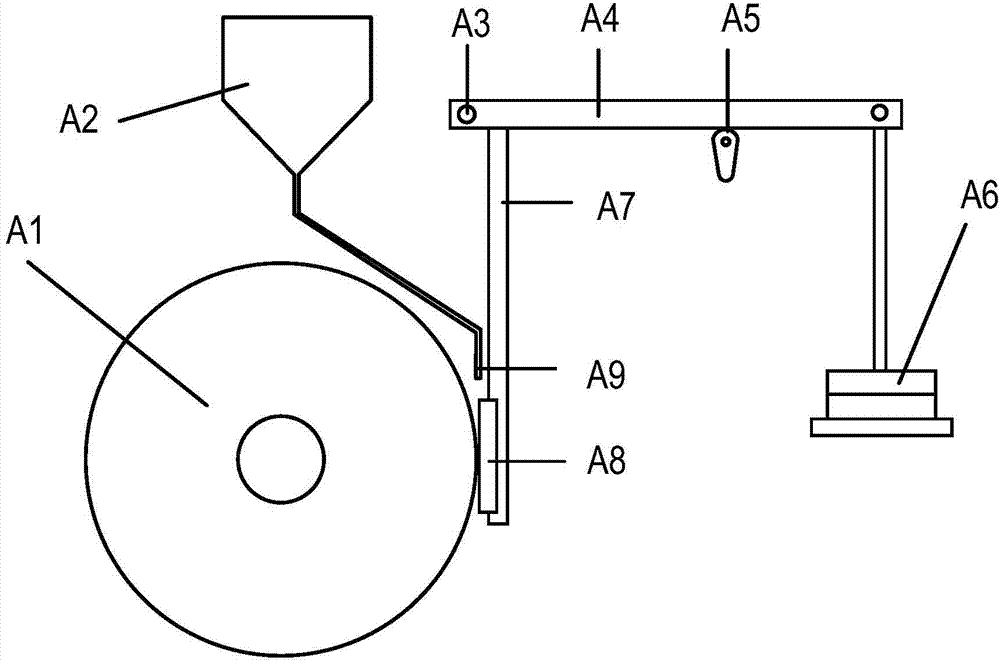

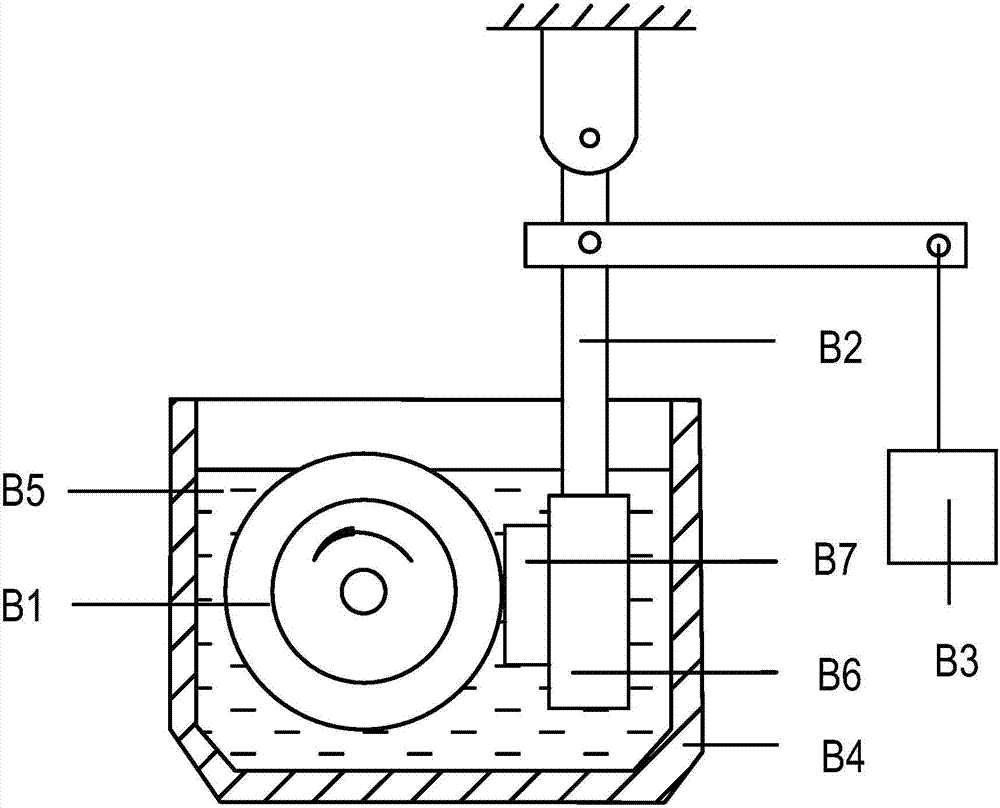

[0037] Such as figure 1 As shown, the wear test device of the present invention comprises a weight 4, a driving motor, a grinding wheel 1 arranged on the rotating shaft of the driving motor, a lever mechanism 2 arranged on one side of the grinding wheel 1 through a loading shaft 3, and the lever mechanism 2 consists of a cross bar 201 It is composed of a vertical bar 202, and a loading bar 7 is arranged under the horizontal bar 201. The end of the horizontal bar 201 away from the vertical bar 202 is provided with a weight mounting hole 203, and the weight 4 is loaded on the horizontal bar 201 through the weight mounting hole 203. On the vertical bar 202 close to the grinding wheel 1, a sample installation port 204 is opened, and the sample installation port 204 faces the grinding wheel 1; it also includes the first spray water pipe 5 arranged directly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com