Current harmonic suppression method for magnetic suspension rotor system based on self-adaptive repetitive controller

A repetitive controller and magnetic levitation rotor technology, applied in the direction of adaptive control, general control system, control/adjustment system, etc., can solve the problem that the repetitive controller cannot be directly applied, affects the convergence speed of the repetitive controller, and the high-frequency harmonics cannot be performed Effectively suppress problems such as

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

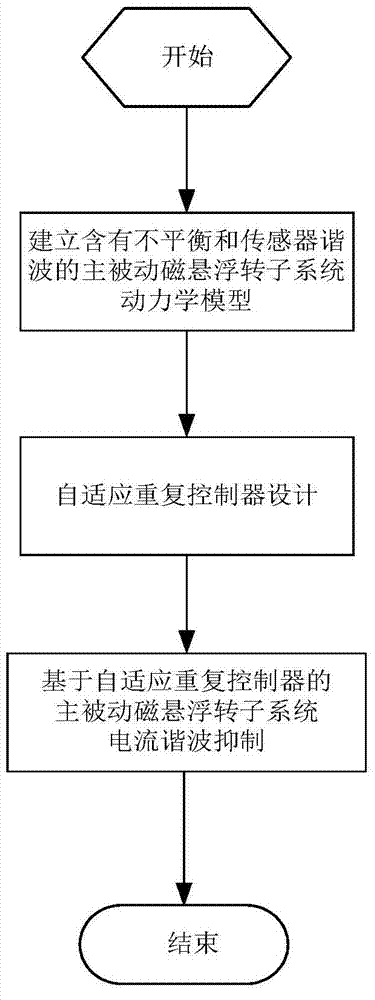

[0037] Such as figure 1 As shown, the implementation steps of a current harmonic suppression method for a magnetic suspension rotor system based on an adaptive repetitive controller of the present invention are to first establish a dynamic model of the active and passive magnetic suspension rotor with unbalance and sensor harmonics, and then design a Adaptive repetitive controller, and finally based on the characteristics of the active and passive magnetic suspension rotor system, the harmonic current suppression method is given.

[0038] (1) Establish a dynamic model of the active and passive magnetic suspension rotor system with unbalance and sensor harmonics

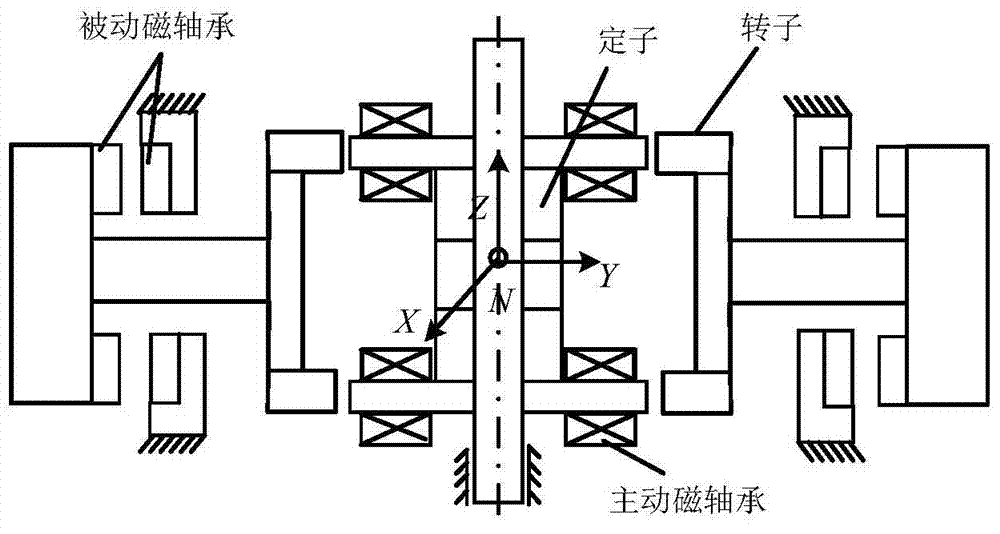

[0039] Two degrees of freedom active and passive magnetic suspension rotor system structure consists of rotor, stator, active magnetic bearing and passive magnetic bearing, such as figure 2 Shown. The active and passive magnetic levitation rotor system adopts suction-type passive magnetic bearings to control the two degr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com