A multi-layer composite acoustic structure for underwater acoustics

A multi-layer composite and acoustic structure technology, applied in the direction of sound-emitting devices and instruments, can solve the problems of complex construction process, long construction time, narrow sound absorption frequency band, etc., and achieve increased transmission distance, excellent sound absorption performance, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in conjunction with accompanying drawing and specific embodiment:

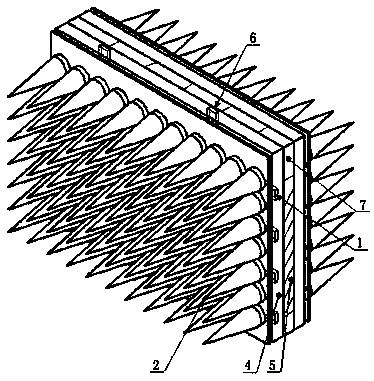

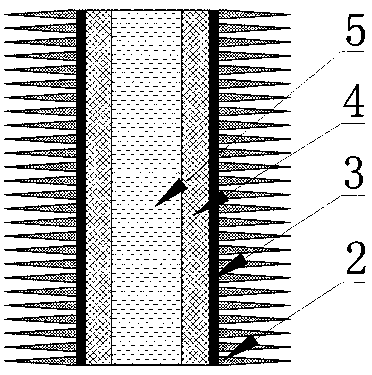

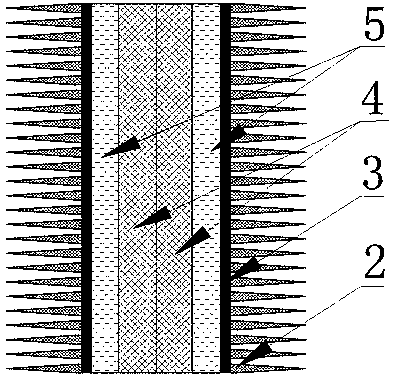

[0020] Such as figure 1 shown, and refer to figure 2 , a multilayer composite acoustic structure for underwater acoustics, the multilayer composite acoustic structure has a support frame 3; the support frame 3 is a rectangular frame of a hollow structure formed by connecting longitudinal beams 6 and crossbeams 1; The outer sides of the support frame 3 are provided with a sound-absorbing layer 2; the sound-absorbing layer 2 is a rubber or polyurethane material with high damping internal friction, the acoustic impedance is close to that of water, and the sound-absorbing layer 2 is a hollow cone shape or prism or rectangular block; the sound-absorbing layer 2 described in this embodiment is a hollow conical shape; the thickness of the sound-absorbing layer 2 is 50-300mm, the thicker the The sound-absorbing frequency band is lower; the sound-absorbing layer 2 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com