Efficient damping type composite floor structure

A combined floor and damping technology, which is applied to floors, building components, building structures, etc., can solve problems such as poor absorption of noise and vibration energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

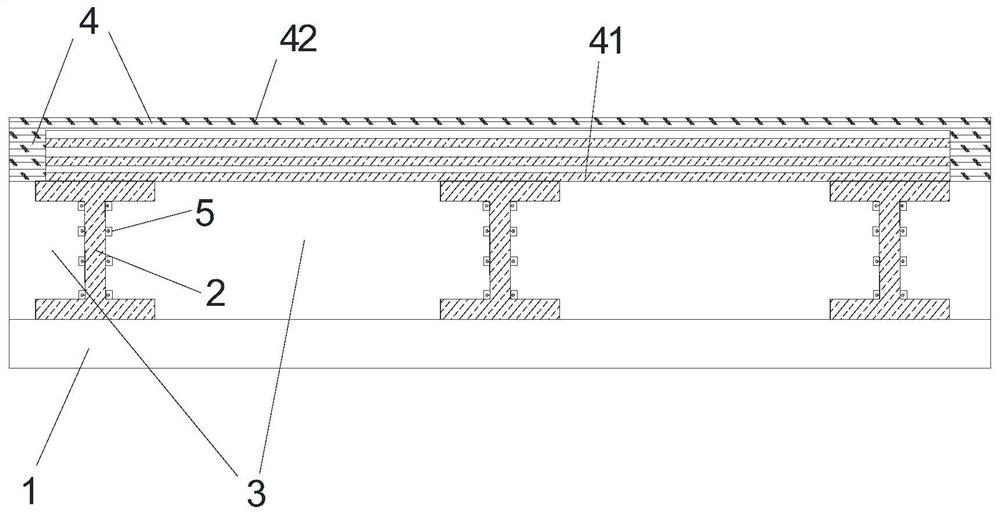

[0033] The high-efficiency damping type composite floor structure in the present invention comprises a fiber cement board 1, a plurality of I-shaped steel beams 2, a concrete layer 3 and a composite damping layer 4, see figure 1 .

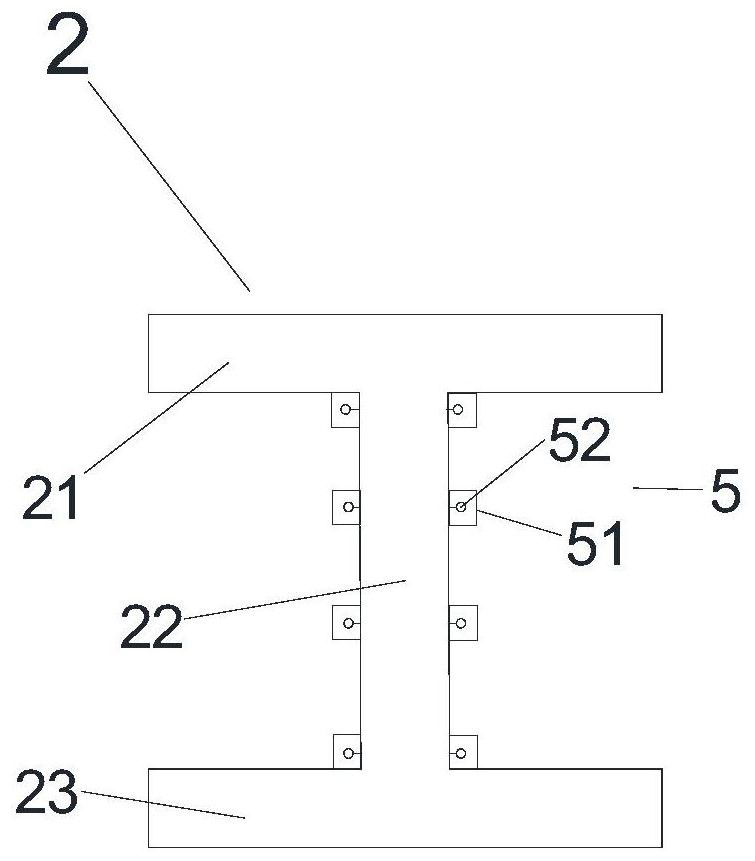

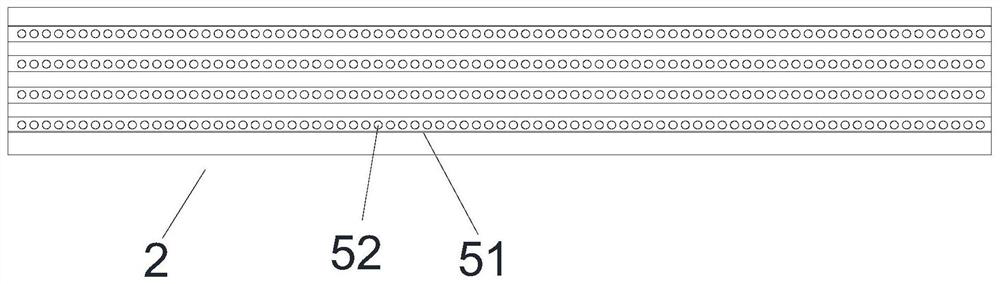

[0034] The I-shaped steel beam 2 is arranged on the fiber cement board 1, and the I-shaped steel beam 2 is provided with a plurality of damping strip tubes 5, see figure 2 and image 3 , the height of the I-shaped steel beam 2 is 5~15cm during concrete implementation.

[0035] The concrete layer 3 is filled on both sides of the I-shaped steel beam 2, so that the concrete layer 3 and the I-shaped steel beam 2 together form a layer structure, which is actually a layer structure with a rectangular cross section.

[0036] The damping strip tube 5 is fixed on the waist 22 of the I-shaped steel beam, and the high-efficiency energy-consuming I-steel structure is constructed through the cooperation of the damping strip tube 5 and the I-shaped steel, so ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com