Tubular bus split conductor clamp fitting

A technology of splitting wires and wire clip fittings, which is applied in the installation of busbars, electrical components, cables, etc., can solve the problems that branch wire clips or busbar clips cannot be replaced separately, and achieve anti-corona performance and anti-corona performance Good, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

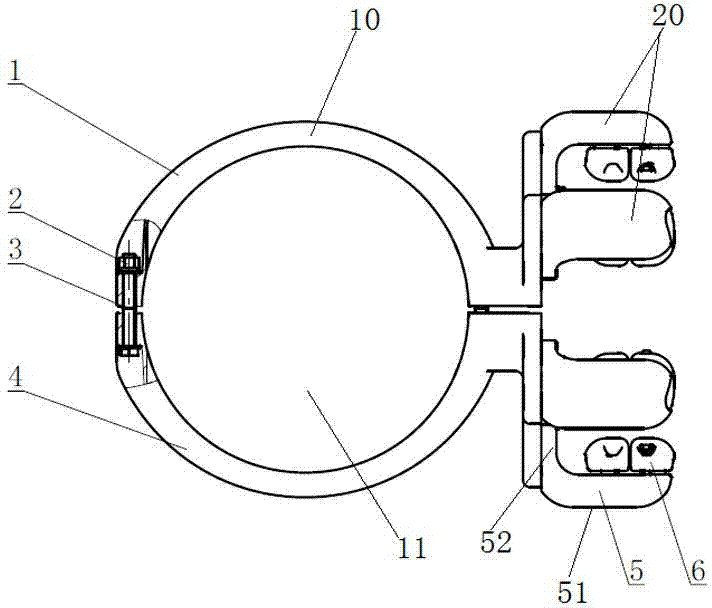

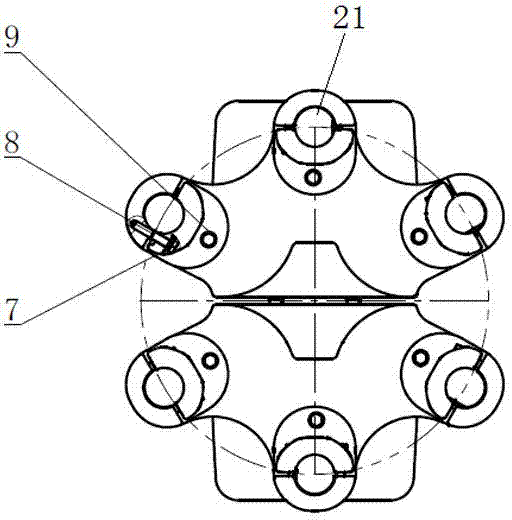

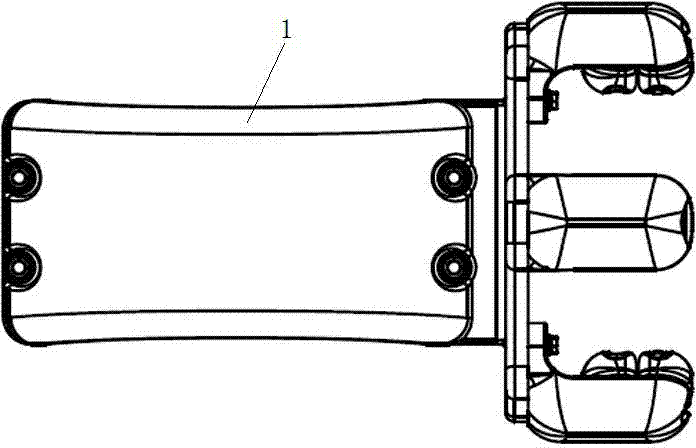

[0024] Such as Figure 1 to Figure 4 Shown, a kind of embodiment of pipe busbar split wire clamp hardware, the line clamp hardware in this embodiment comprises busbar clamp 10, and busbar clamp 10 is provided with the busbar hole 11 that is used for clamping pipe busbar, in the busbar clamp 10 One end is fixed with six branch line clamps 20 uniformly distributed around the circumferential direction, and each branch line clamp 20 is respectively provided with branch line holes 21 for clamping split branch wires, and the central axes of the branch line holes 21 of the six branch line clamps 20 are parallel and uniform. It is perpendicular to the central axis of the busbar hole 11.

[0025] In this embodiment, the bus bar clamp 10 is assembled by the first split body 1 and the second split body 4, the two splits are fixedly assembled together by connecting bolts 2, and when the two splits are connected There is also a second seal ring 3 set on the connecting bolt 2 on the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com