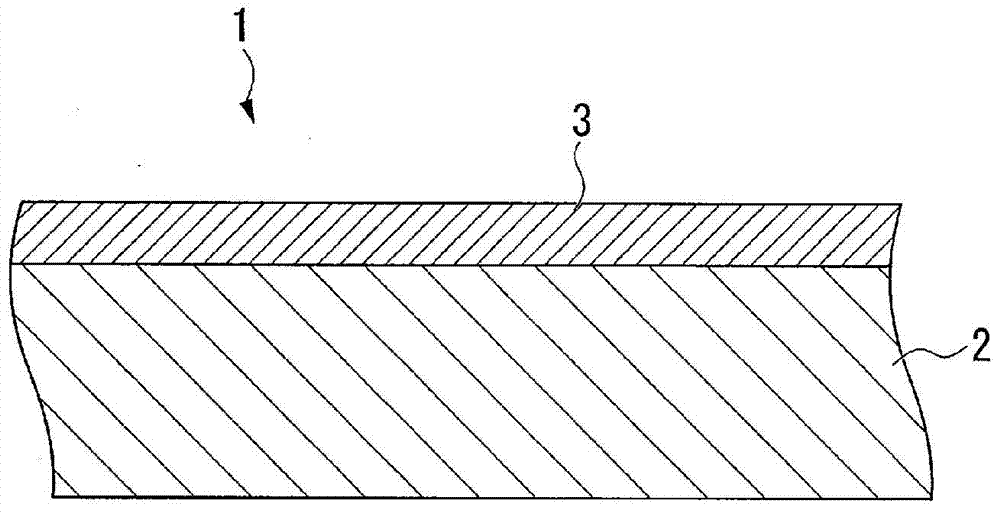

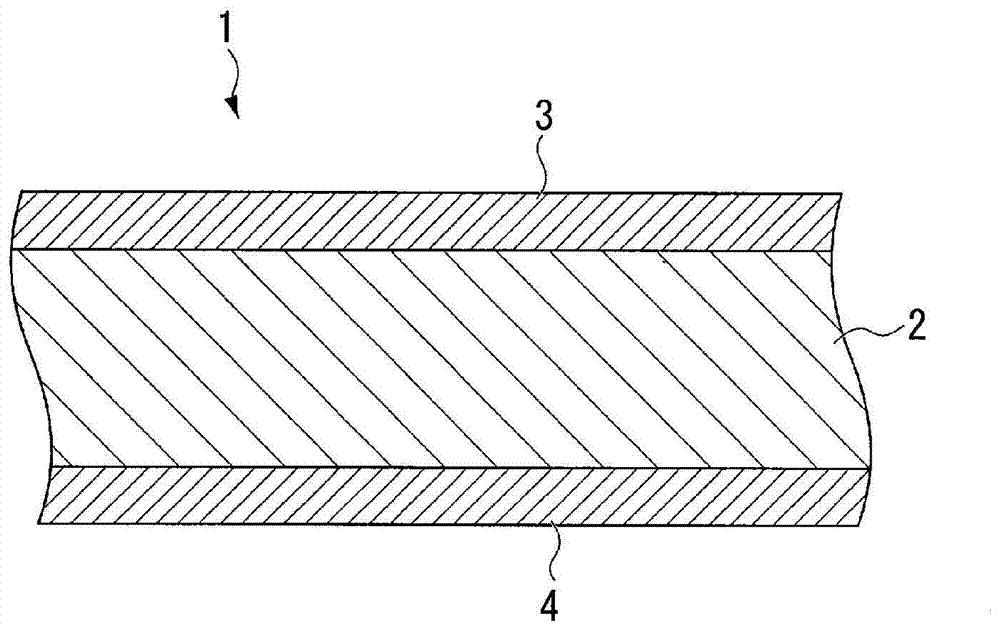

Mold release film

A release film and release layer technology, applied in film/sheet-like adhesives, electronic equipment, applications, etc., can solve the problems of peelability (decreased release properties, decreased pressure lamination workability, etc.)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

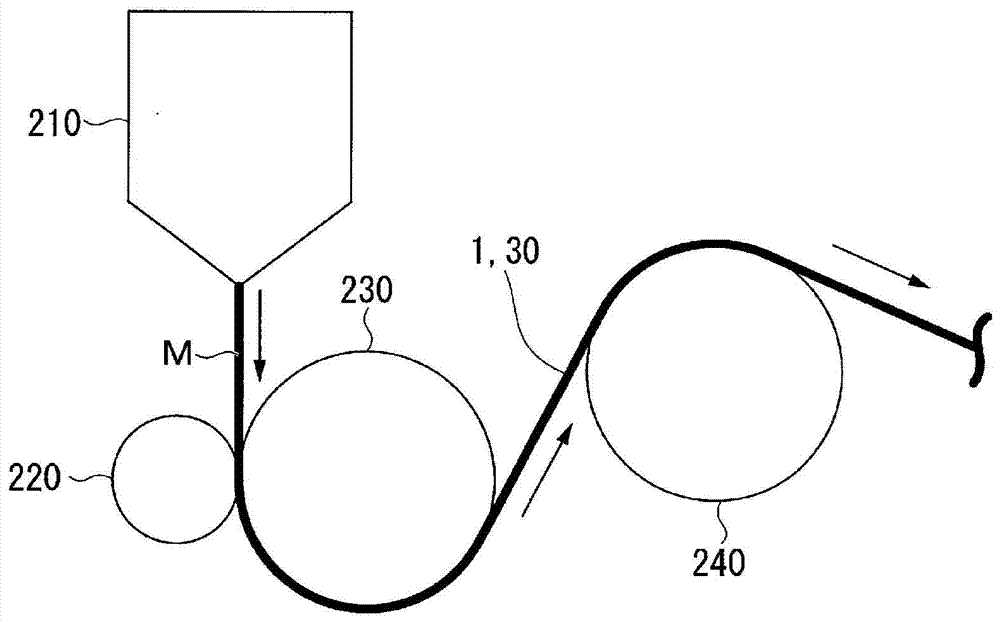

Method used

Image

Examples

Embodiment 1

[0133] (1) Raw materials for the first release layer and the second release layer

[0134] First, SPS resin (manufactured by Idemitsu Kosan Co., Ltd., XAREC S104) was prepared as raw materials for the first release layer and the second release layer, respectively.

[0135] (2) The raw materials of the base

[0136] In addition, the following resins were prepared as raw materials of the base layer.

[0137] ・SPS resin (manufactured by Idemitsu Kosan Co., Ltd., XAREC S104) 20 parts by mass

[0138] 80 parts by mass of polyolefin resin

[0139] In addition, polyolefin resin is a mixture of several resins, and the content is as follows. In the following description and Tables 1 and 2, the ethylene-methyl methacrylate copolymer is indicated as EMMA, the ethylene-styrene copolymer is indicated as AD, and the polypropylene is indicated as PP.

[0140] EMMA (manufactured by Sumitomo Chemical Co., Ltd., ACRYFT WD106) 30 parts by mass

[0141] AD (manufactured by Mitsubishi Chemica...

Embodiment 2~9

[0149] As shown in Table 1, except having changed the layer constitution and manufacturing conditions of the release film, it carried out similarly to Example 1, respectively, and manufactured the release film. In addition, in some examples, N,N',N"-tris[2-methylcyclohexyl]-1,2,3-propanetricarboxamide was used as a nucleating agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com