Ink ribbon cassette, ink ribbon cartridge, printing device and printing device control method

A technology of printing device and ink ribbon box, which is applied in the direction of ink ribbon box, inking device, printing, etc., and can solve the problem that the ink ribbon support does not have coverage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0091] (Schematic structure of printing device)

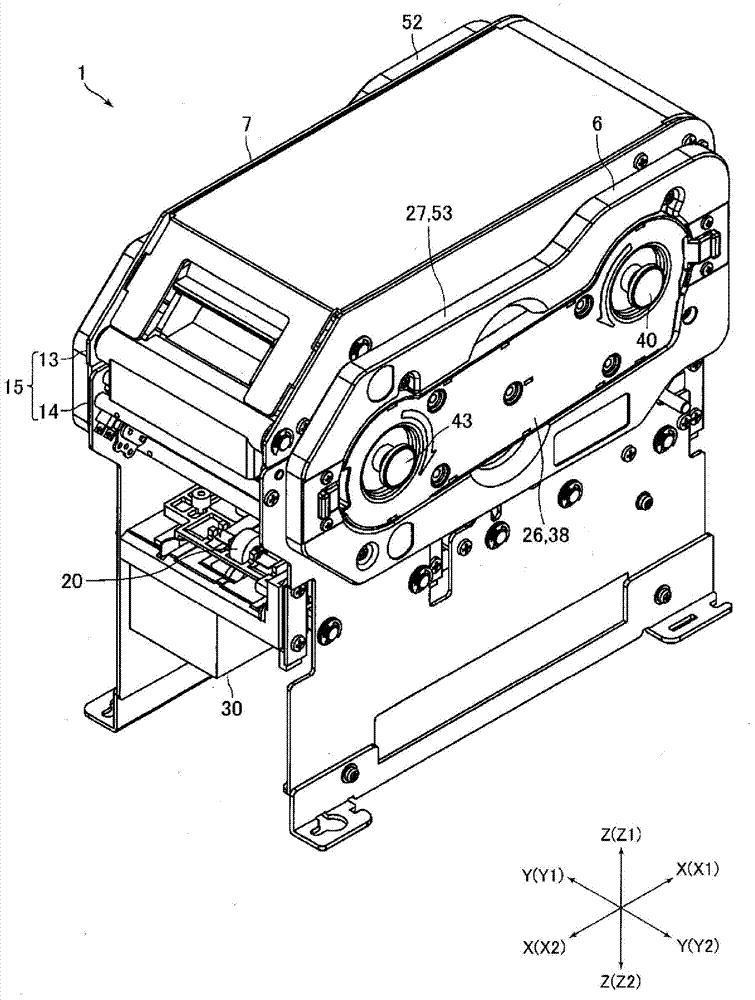

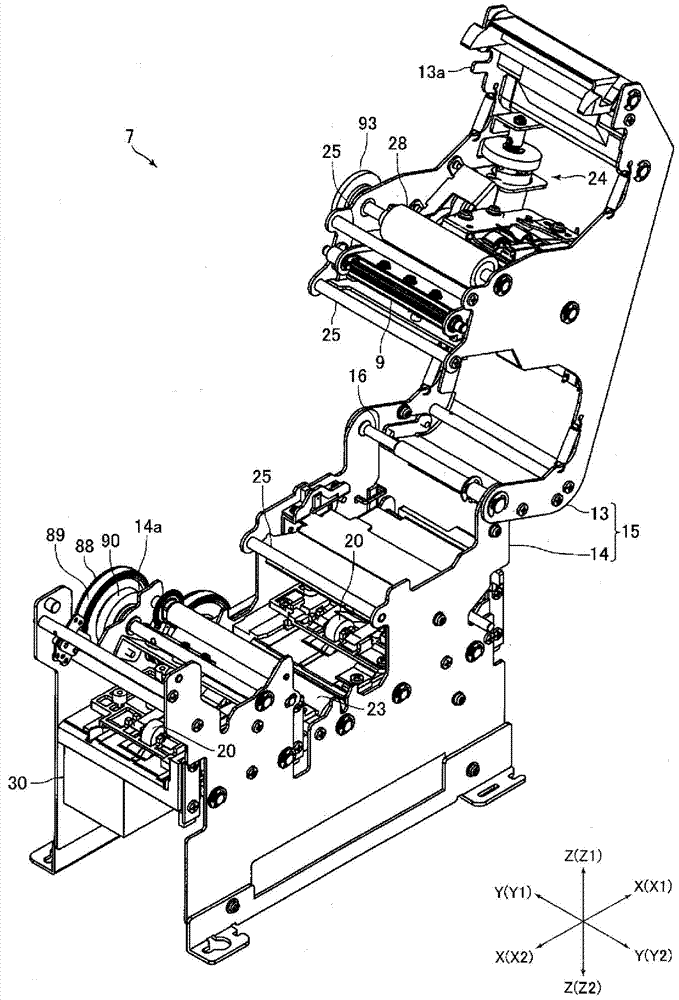

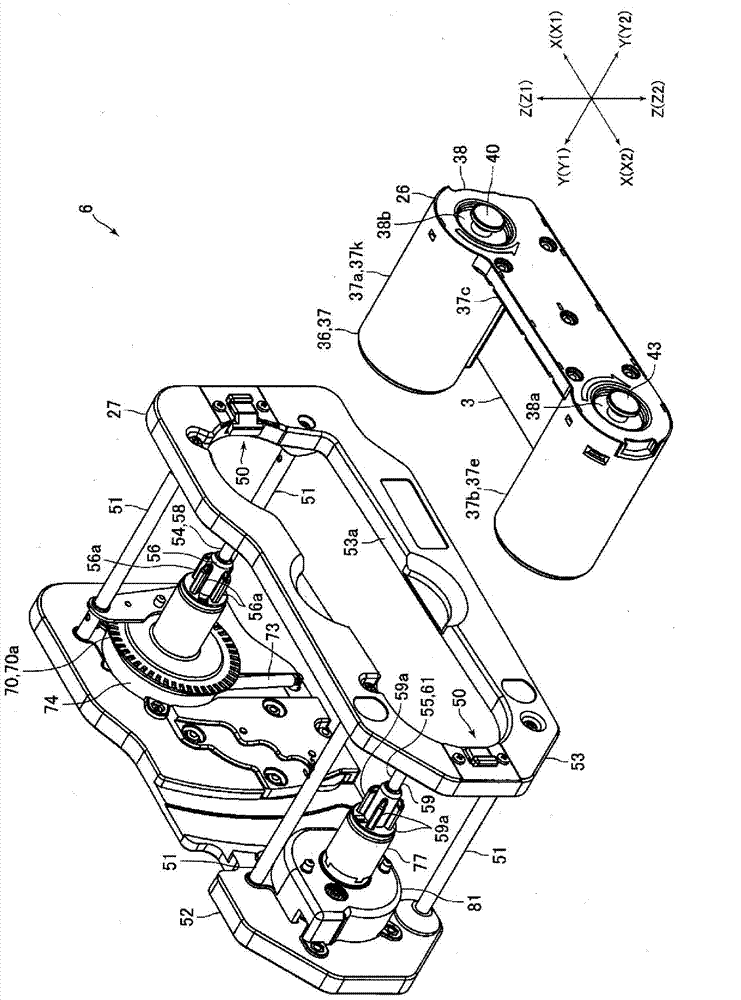

[0092] figure 1 It is a perspective view of the printing device 1 according to the embodiment of the present invention. figure 2 for from figure 1 The illustrated printing device 1 is a perspective view after the ink ribbon cartridge 6 is removed. image 3 for figure 1 An exploded view of the ribbon holder 6 is shown. Figure 4 for side description figure 1 A diagram of the internal structure of the printing device 1 is shown. Figure 5 for Figure 4 A top view of a portion of the ink ribbon 3 is shown.

[0093] The printing device 1 of this mode is used for printing a card 2 as a printing medium (refer to Figure 4 ) A device that prints images such as text, symbols, and graphics. Specifically, the printing device 1 uses an ink ribbon 3 formed by applying ink to a strip-shaped film, and heats the ink on the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com