Apparatus and method for subsea testing

A kind of equipment and seabed technology, applied in the field of seabed testing equipment, can solve the problems of weakening productivity advantages, human errors, and inability to determine the measurement data of ore-bearing grades, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

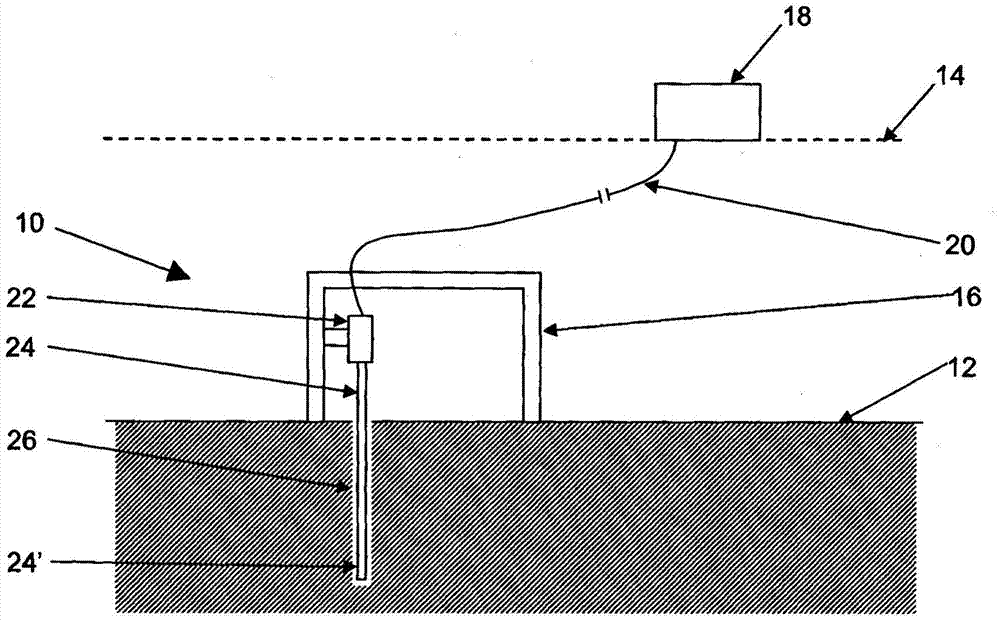

[0031] figure 1 A schematic diagram showing a seabed drilling operation 10 on a seabed 12 below sea level 14 is shown. The seabed drilling operation 10 may be located at various depths below sea level 14, but typically the seabed 12 will be more than 1000 m below sea level 14, and in many cases approximately 2000-3000 m below sea level 14 .

[0032] A seabed drilling operation 10 has seabed drilling equipment 16 connected by an 'umbilical' cable 20 to a surface support vessel or platform 18 . The umbilical 20 provides power, control and telemetry to the seabed drilling equipment 16 . Typically, seabed drilling equipment 16 is powered and operated remotely from a surface support vessel or platform 18 via an umbilical 20 . Although the surface support vessel or platform 18 is shown positioned on the surface of the sea level 14, it will be understood that the surface support vessel or platform may be positioned elsewhere, such as on land.

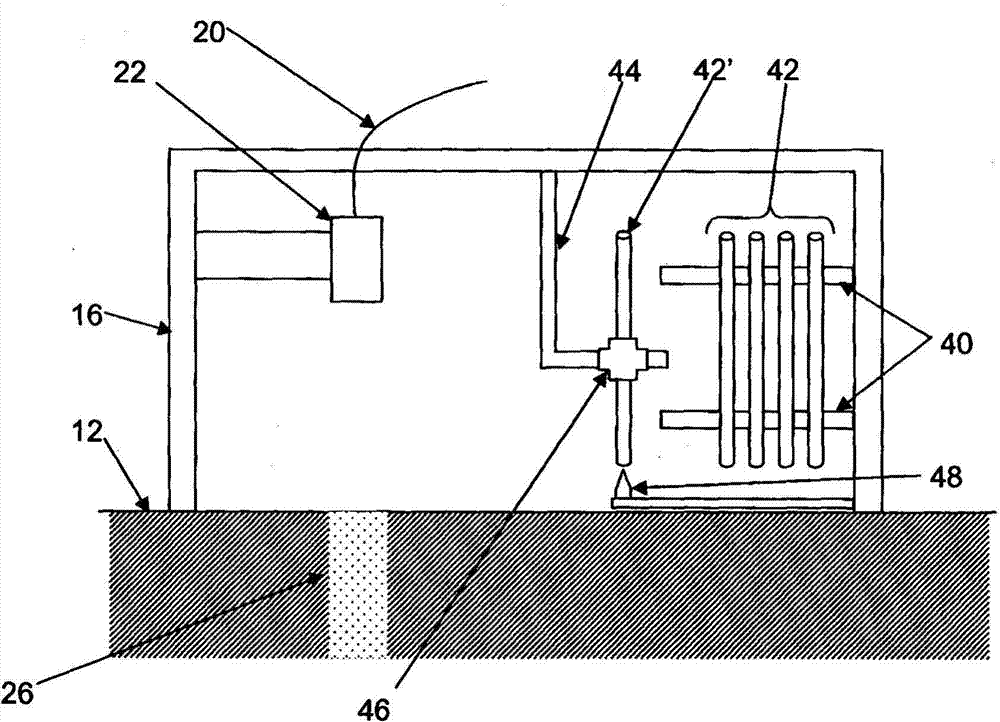

[0033] The seabed drilling rig 16 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com