Remote control system and method for flue-cured tobacco shed

A remote control system and control system technology, applied in the field of automatic control, can solve problems such as affecting the yield of flue-cured tobacco, and achieve the effects of flexible layout and improved yield and quality of flue-cured tobacco

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

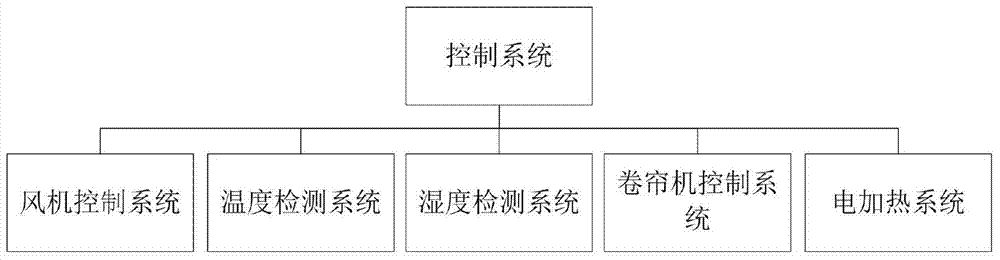

[0017] The remote control system of the flue-cured tobacco shed includes a remote control terminal, which is respectively connected to a temperature detection system, a humidity detection system, a roller shutter machine control system, an electric heating system and a fan control system through a transmission system; the fan control system includes an air inlet fan and a fan control system. The air exhaust fan and the air inlet fan are arranged at the bottom of the side wall of the flue-cured tobacco shed, and the exhaust fan is arranged at the upper part of the opposite side wall where the air inlet fan is located. The transmission system is a wireless transmission system, and the remote control terminal performs data transmission between the temperature detection system, humidity detection system, roller shutter control system, electric heating system, water spray system and fan control system through the wireless network. A display terminal is installed in the flue-cured sh...

Embodiment 2

[0020] The difference from Embodiment 1 is that the transmission system is a CAN bus transmission system, and the remote control terminal communicates with the temperature detection system, humidity detection system, roller shutter control system, electric heating system, water spray system and fan control system via the CAN bus. for data transfer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com