Inner mold pressing helmet with pivotable protective guard

A technology for helmets and shields, applied in the field of internally molded helmets with pivotable shields, which can solve problems affecting aerodynamics, weight distribution, balance, deformation, uncomfortable helmets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Unless otherwise specifically stated, all tests herein are carried out under standard conditions, which may include space and test temperature of 25°C, air pressure at sea level (1 atm), pH of 7, and all measurements are Do it in metric units. In addition, all percentages, ratios, etc. herein are by weight unless otherwise specified.

[0017] Unless otherwise expressly indicated, the terms "inner", "inner" and "inner side" as used herein refer to the relative position of the wearer's head toward the helmet portion, or the closer the helmet portion is to the wearer's head relative position. Unless otherwise expressly indicated, the terms "outside", "external" and "external" as used herein refer to the relative position towards the outer side of the helmet of the helmet part, or the relative position of the helmet part closer to the outer side of the helmet. The outer side is / or away from the wearer's head.

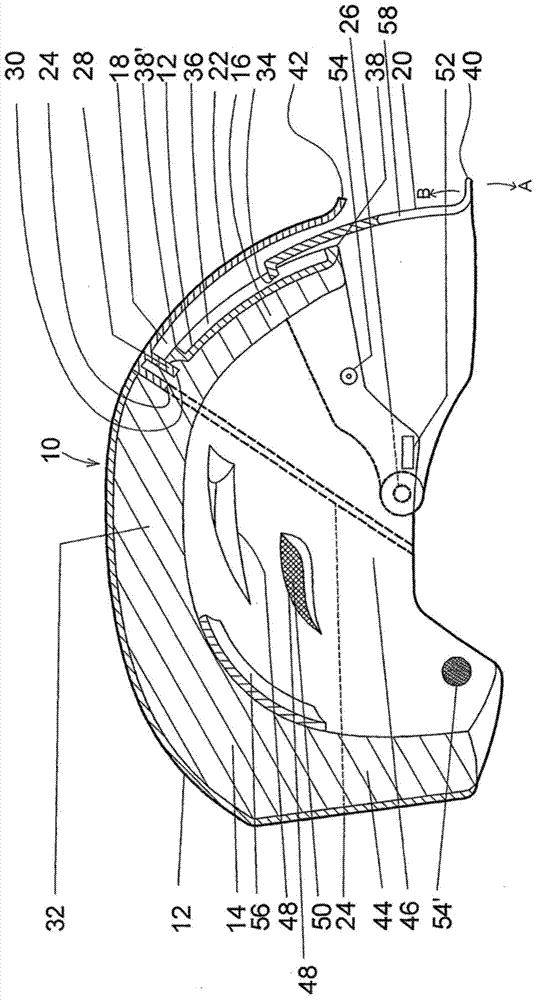

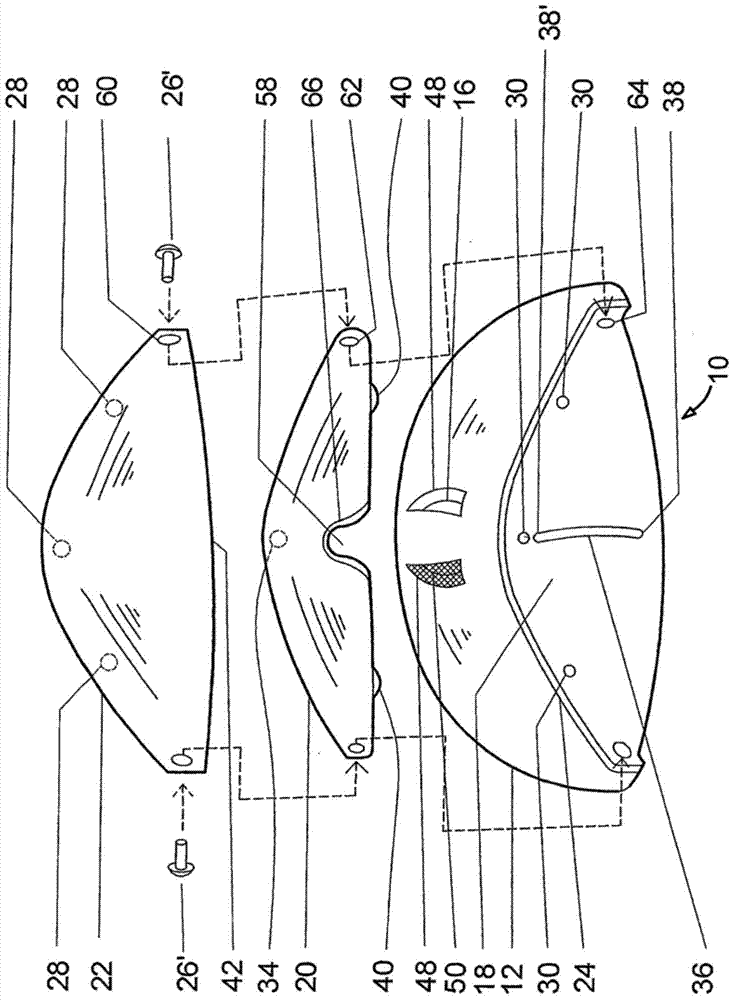

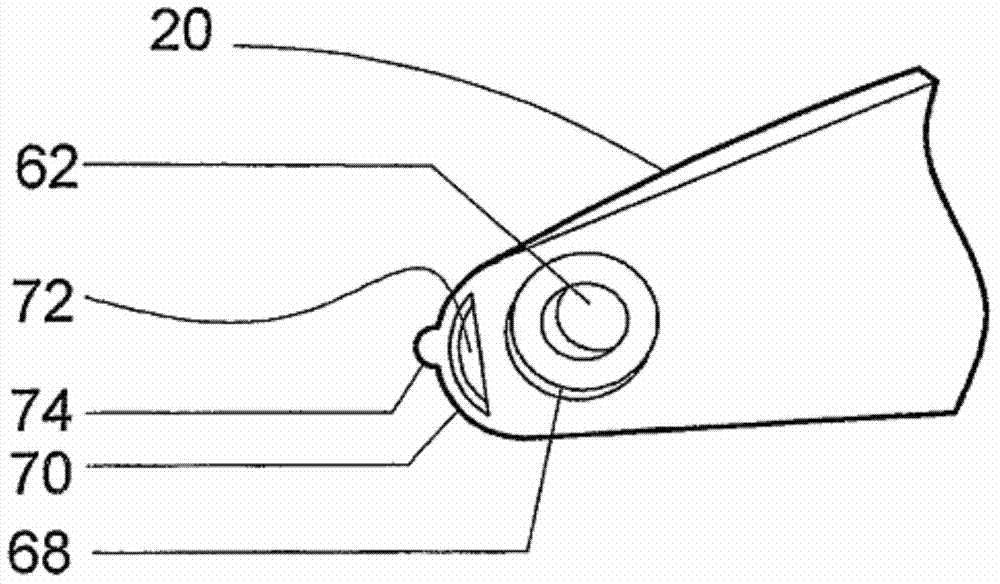

[0018] Embodiments of the present invention relate to a helm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com