Multichannel injection type fracturing liquid mixing and blending device

An injection-suction, fracturing fluid technology, applied in mixers, fluid mixers, dissolving and other directions, can solve the problems that the quality of fracturing fluid cannot be fully guaranteed, cannot achieve fast and sufficient mixing, and the structure is complex, and The effect of fast and thorough glue, simple structure and strong suspension ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

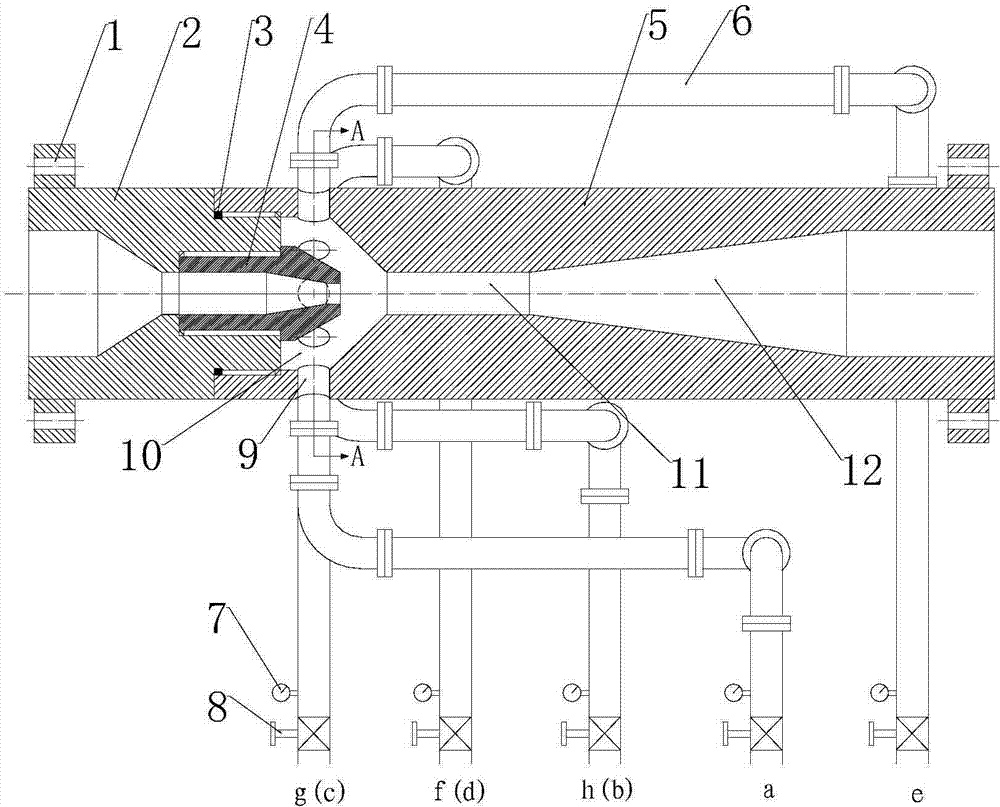

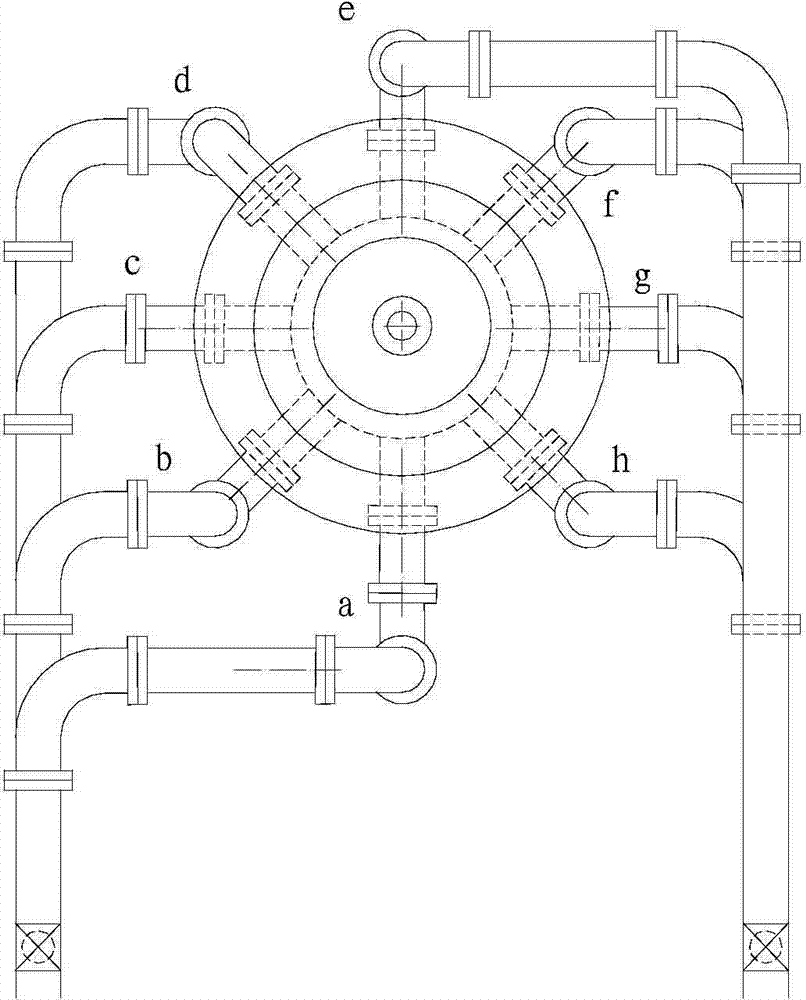

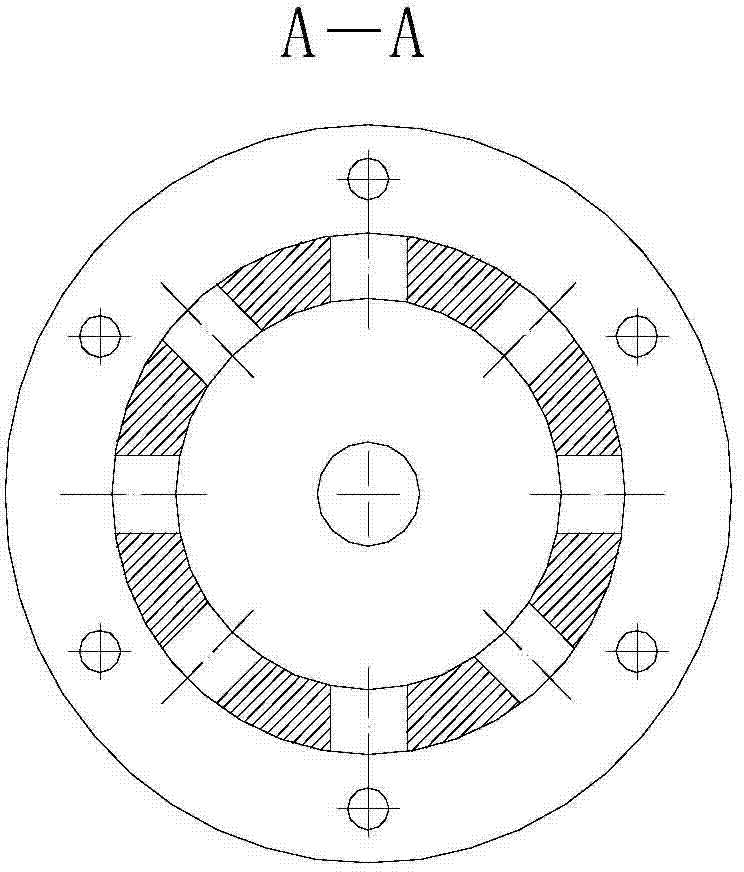

[0021] See attached figure 1 , a multi-channel ejector-suction fracturing fluid mixing device, mainly composed of a connecting flange 1, a joint 2, a sealing ring 3, a nozzle 4, a vacuum pump body 5, a manifold system 6, a flow meter 7, and an automatic valve 8. The main body of the mixing device includes a jet-suction pump and a manifold system 6 connected to the jet-suction pump. The inlet and outlet ends of the jet-suction pump are respectively connected with flanges. The pump outlet line is connected to the mixed solution outlet line. The jet-suction pump includes a joint 2 and a vacuum pump body 5. The vacuum pump body 5 is provided with a number of liquid suction holes 9 communicating with the vacuum cavity 10 of the jet-suction pump. The liquid suction holes 9 are arranged reasonably according to the actual situation; the manifold system 6 includes A plurality of suction lines for conveying liquid additives are respectively installed on the liquid suction holes 9 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com