Eddy current loss-free magnetic separator

A magnetic separation, no eddy current technology, used in magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of short service life, easy damage to equipment, easy wear and tear of cylinder skin, etc., to achieve long service life, improve processing quantity, prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

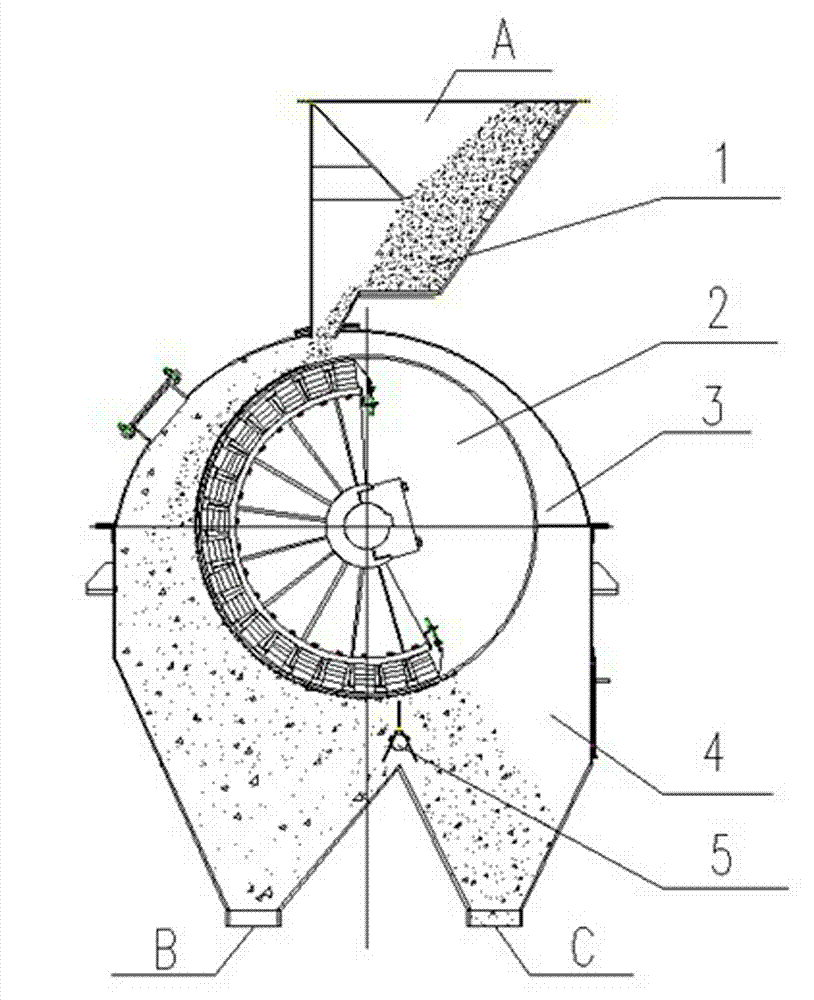

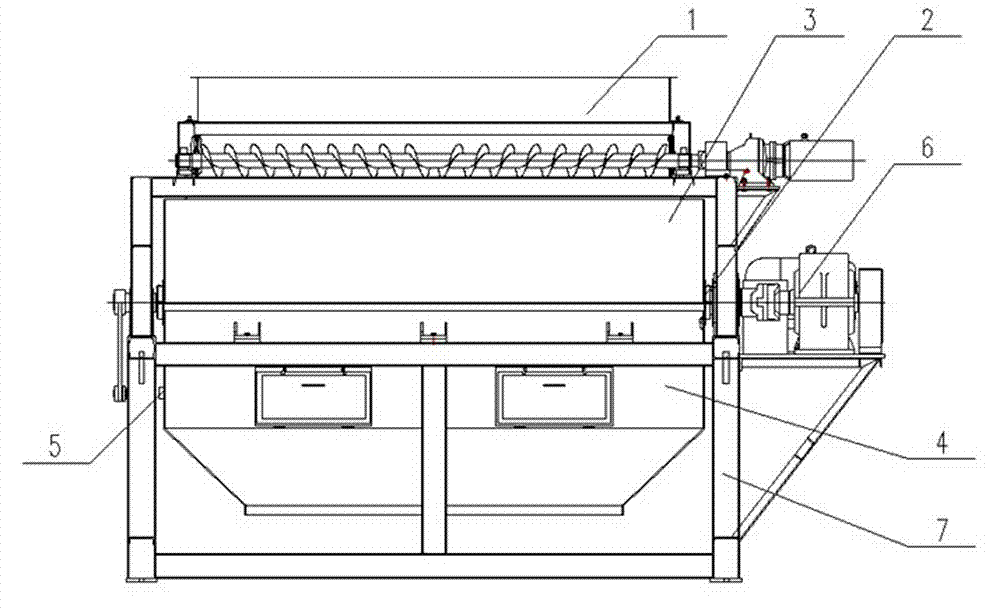

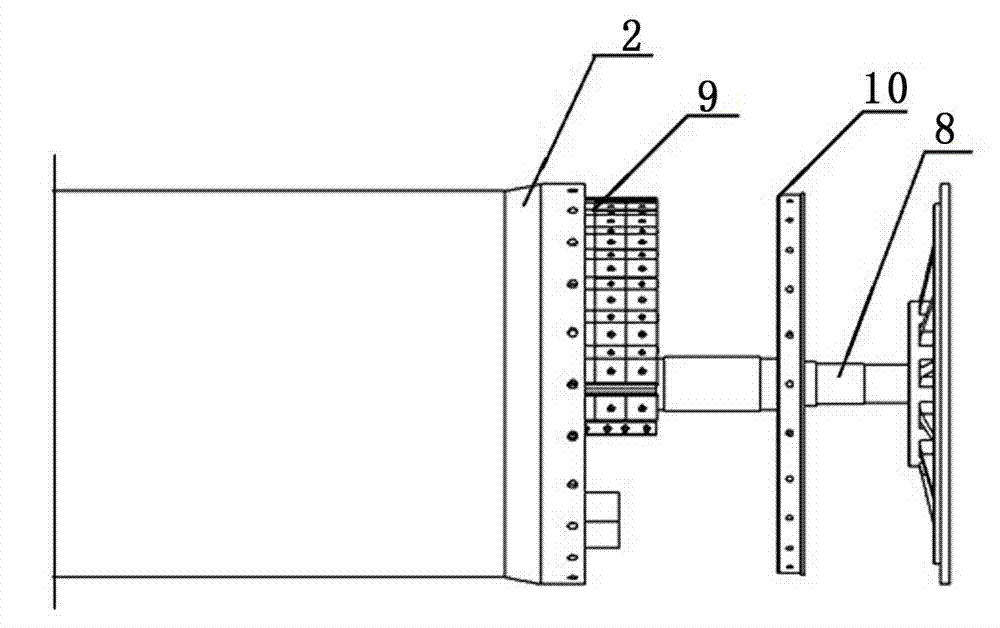

[0015] according to Figure 1~4 The specific structure of the present invention will be described in detail. The magnetic separator without eddy current loss includes an upper box body 3, a lower box body 4, a permanent magnet cylinder body 2, a material distribution device 5 and a drive motor 6 for driving the permanent magnet cylinder body 2, etc. components. Wherein, the upper box body 3 is an arc-shaped structure, and the top of the arc-shaped structure is provided with a distributing device 1 , and a distributing roller is arranged in the distributing device 1 . The bottom of the lower box body 4 is a W-shaped structure, one of the feet of the W-shaped structure is the tailings port B, and the other foot is the concentrate port C. There is a permanent magnet cylinder 2 between the upper box 3 and the lower box 4. The permanent magnet cylinder 2 is provided with a main shaft 8 connected to the output end of the drive motor 6. The two ends of the main shaft 8 are limited ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com