Steel ball drying and cleaning device

A technology for cleaning equipment and steel balls, which is applied to drying, drying machines, lighting and heating equipment, etc., which can solve the problems of high labor intensity, large water consumption, and low production efficiency, and reduce the incidence of mixed use of steel balls , Convenient loading and unloading, less water consumption for cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

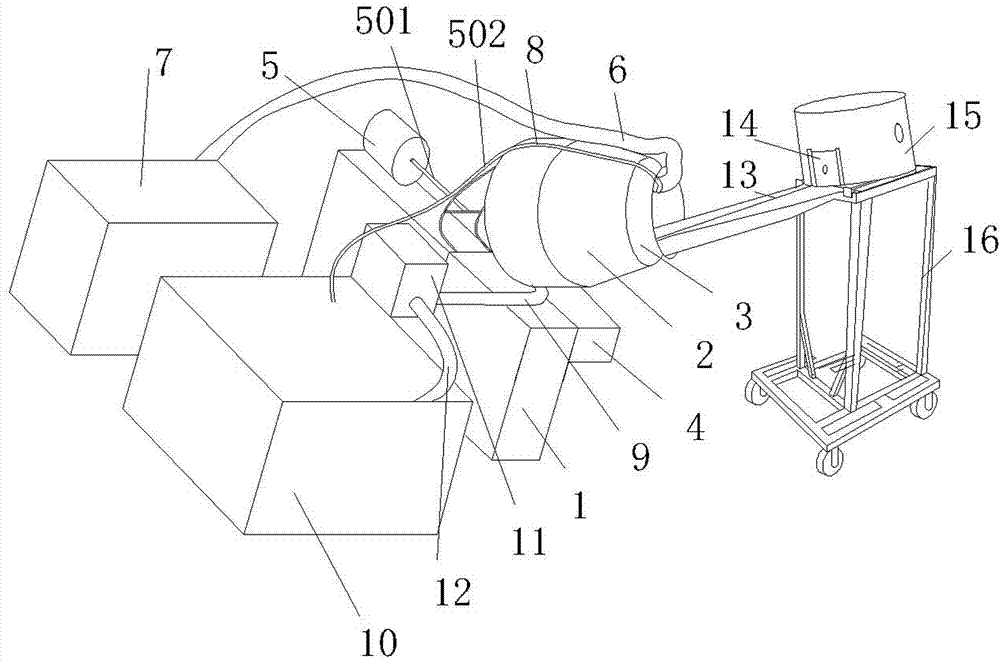

[0025] In this embodiment, the structure of the present invention is described in detail with reference to the accompanying drawings.

[0026] Please refer to the accompanying drawings, the steel ball drying and cleaning equipment provided by the present invention includes:

[0027] The drum mechanism includes an outer cylinder 2 slanted and pivotally connected to the machine base 1 . A rotatable cleaning inner cylinder 3 is coaxially arranged in the outer cylinder 2 , and the inner cylinder 3 is driven by the cleaning motor 4 through the transmission mechanism.

[0028] The overturning mechanism connects the outer cylinder 2 and the base 1, and the outer cylinder 2 and the inner cylinder 3 are simultaneously tilted and turned over by the cylinder 5 of the overturning mechanism.

[0029] The drying mechanism includes a hot air pipe 6 inserted into the inner cylinder 3 , and the hot air pipe 6 is connected to the hot air blower 7 .

[0030] The water circulation system include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com