Bilateral equidistant conveying device and stacking machine using the device

A handling device, equidistant technology, applied in the direction of object stacking, transportation and packaging, conveyor objects, etc., can solve the problems of inflexible handling, complex structure, single function, etc., to reduce the number of drives, simplify the control mechanism, The effect of increasing the range of motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, the present invention will be described in detail by using figures and words.

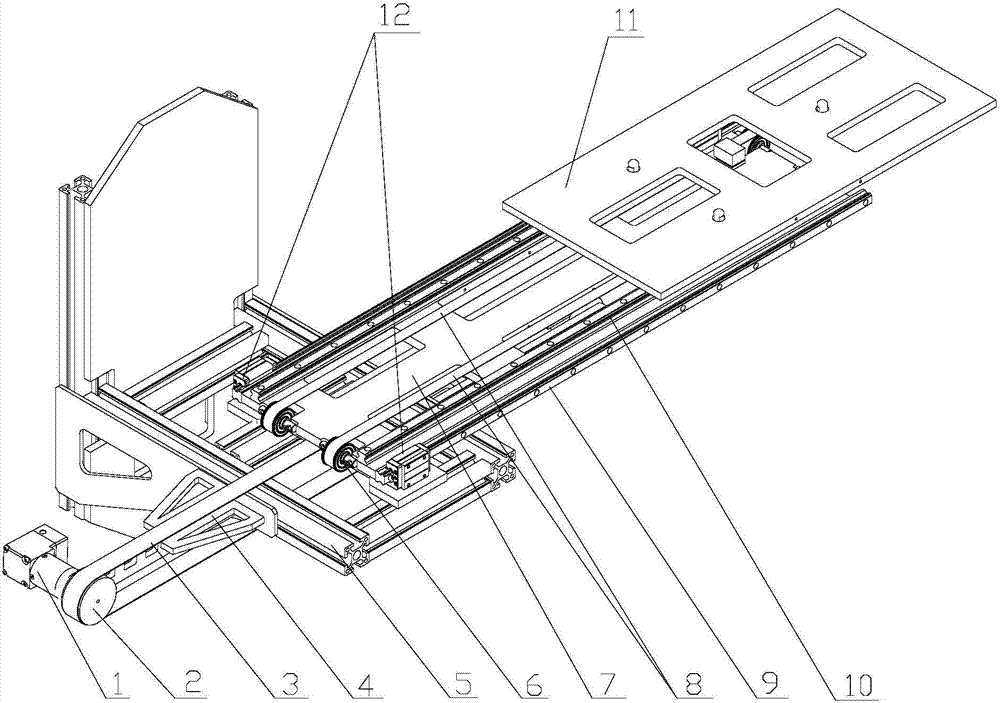

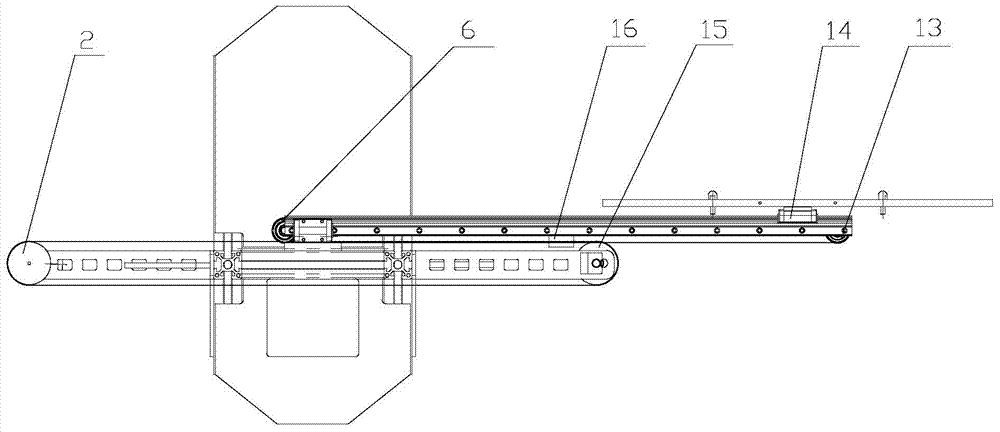

[0020] figure 1 with figure 2 An embodiment of a double-sided equidistance conveying device of the present invention is shown: the double-sided equidistance conveying device comprises a driving device 1, a fixed frame 5, a bottom bracket 4, a middle plate 7 and an upper supporting plate 11, and the Both the driving device 1 and the bottom bracket 4 are installed on the fixed frame 5, and the first-level driving wheel 2 and the first-level driven wheel 15 connected to each other through the first-level stroke synchronous belt 3 are installed on the bottom bracket 4, and the middle plate 7 The middle part of the bottom end of the middle plate is fixedly connected with the first-stage stroke synchronous belt 3 through the fixed splint 16, and the second-stage stroke synchronous belt 8 is installed on the middle plate 7 through the synchronous pulley 6 and the second-stage driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com