Variable valve device of internal combustion engine

An internal combustion engine and valve technology, which is applied to valve devices, mechanical equipment, engine components, etc., can solve the problems of complicated working methods of switching pins, and achieve the effect of simplifying the structure and working methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

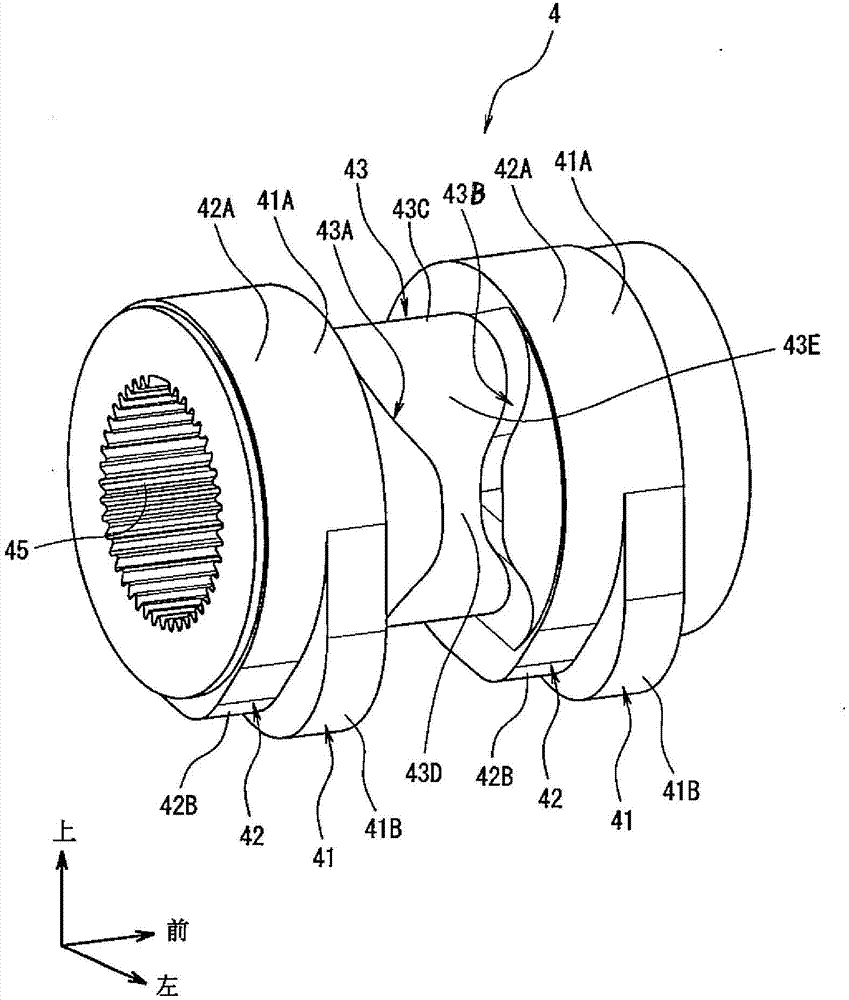

[0105] The embodiments have been described above, but the present invention is not limited thereto. For example, in the above-described embodiment, the 2-stage variable valve device applied to the high-speed cam 41 and the low-speed cam 42, but as Figure 9 As shown in the cam holder 4A, if the second cam 42 is set as a stop cam having a peripheral surface (all of which are base circle portions 42 ) whose lift is 0, the valve stop function can be realized. According to such a configuration, the structure and operation method of the mechanism for switching the cam can be simplified, and the valve can be stopped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com