Draught fan assembling modality adjusting system and draught fan system

A technology for adjusting the system and assembly mold, applied in the direction of machine/engine, mechanical equipment, liquid fuel engine, etc., can solve the problem of inability to obtain assembly modal data sheet noise diagnosis, inability to predict and analyze the mass distribution of contact points, and assembly modal failure. change, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

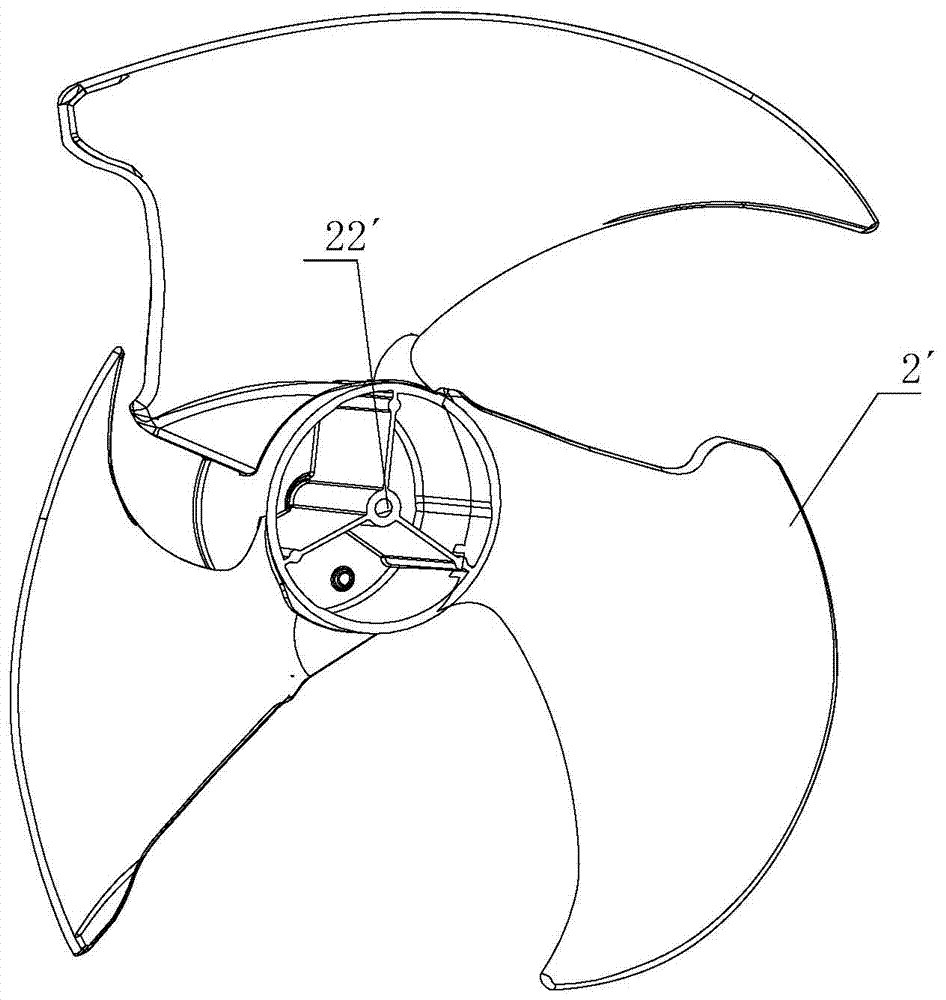

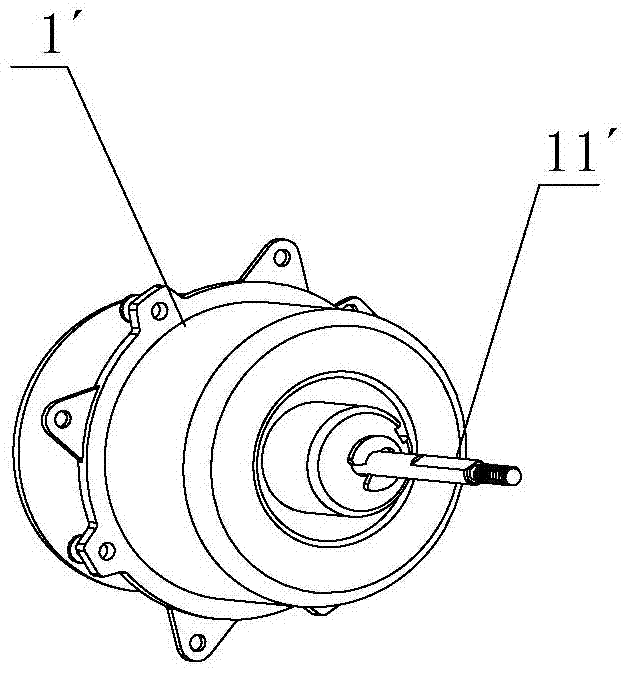

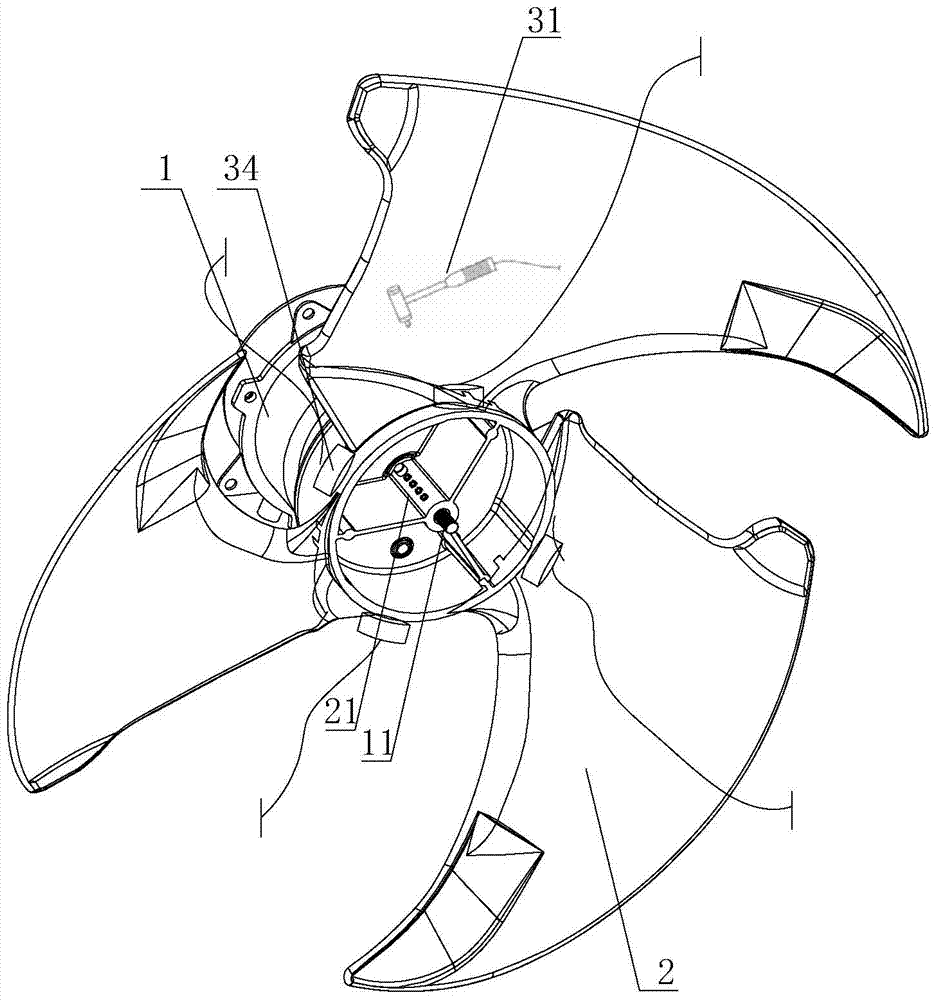

[0029] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solution of the invention described in the claims.

[0030] According to the dynamic equations and modal theory, the modal includes the fixed frequency and mode shape independent of the load, as well as the damping characteristics determined by the characteristics of the system itself. The mode shape is a local quantity, and the fixed frequency and damping are global quantities. As shown in the following formula, the fixed frequency mainly depends on the stiffness matrix and the mass distribution matrix, and the mode shape is a local quantity related to the fixed frequency, mass matrix and stiffness matrix. Adjust the mass distribution and constraint condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com