A mobile shielded iron box

A mobile, iron-box technology, which is applied in nuclear engineering and protected small rooms, etc., can solve the problems of heavy shielding devices, reduce shielding radiation, and thick concrete, so as to achieve good shielding effect and avoid radiation leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

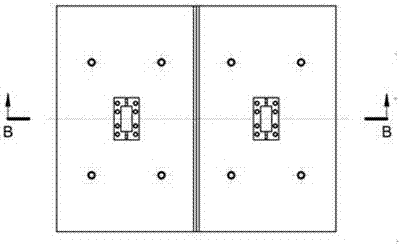

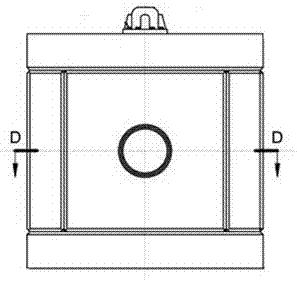

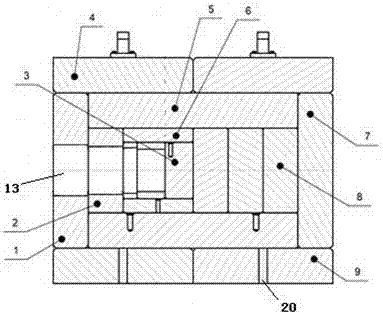

[0022] Such as Figure 1-6 Shown: a mobile shielding iron box, characterized in that the mobile shielding iron box is made of twelve types of twenty-three iron blocks, and the material of the iron blocks is Q235B; among them, one The size of Iron 1 is 1100mm x 1100mm x 250mm, the size of Iron 2 is 600mm x 600mm x 250mm, the size of Iron 3 is 400mm x 400mm x 500mm, and the size of Iron 4 is 1000mm x 1600mm x 250mm, size 5 iron 5 is 1500mm x 1100mm x 250mm, size 6 iron 6 is 600mm x 500mm x 100mm, size 7 iron 7 is 1100mm x 1100mm x 250mm, size 8 iron The size of 8 is 600mm x 600mm x 250mm, the size of nine iron 9 is 1000mm x 1600mm x 250mm, the size of ten iron 10 is 1000mm x 1100mm x 250mm, the size of eleven iron 11 is 1500mm x 600mm x 250mm, the size of No. 12 iron block 12 is 500mm x 400mmx 100mm; the quantities of each iron block are respectively: No. 1 iron block 1, No. 2 iron block 2, No. 3 iron block 3, and No. 7 iron block 7, one each, No.4 iron 4, No. 5 iron 5, No. 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com