Ship

A technology for ships and hulls, applied in the field of ships with multiple cargo compartments, can solve problems such as increased weight, hull damage, increased power consumption of counterweight pumps or counterweight water treatment devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

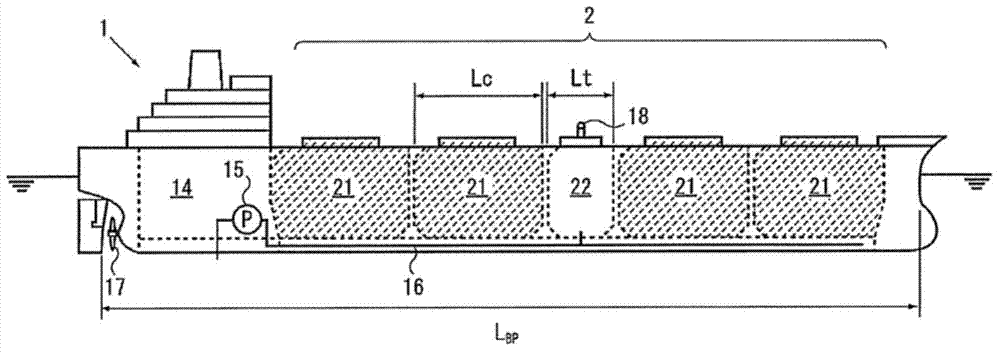

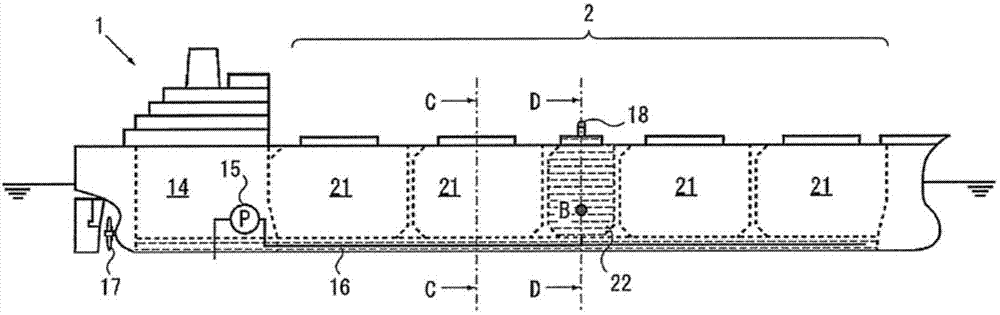

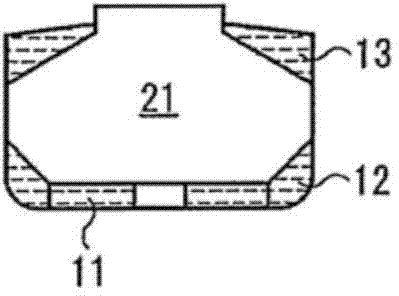

[0038] Embodiments of the present invention will be described below with reference to FIGS. 1 to 3 . here, Figure 1A ~ Figure 1D It is a figure which shows an example of the ship of the 1st Embodiment of this invention, Figure 1A It is the overall composition diagram of cargo transportation, Figure 1B It is the overall composition diagram in stormy weather, Figure 1C yes Figure 1B The C-C sectional view of Figure 1D yes Figure 1B The D-D cross-section. in addition, Figure 2A ~ Figure 2D is a diagram showing an example of a ship of the prior art, Figure 2A It is the overall composition diagram of cargo transportation, Figure 2B It is the overall composition diagram in stormy weather, Figure 2C yes Figure 2B The C-C sectional view of Figure 2D yes Figure 2B The D-D cross-section.

[0039] Such as Figure 1A ~ Figure 1D As shown, the ship 1 according to the first embodiment of the present invention is a ship provided with a plurality of cargo holds 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com