A seed shelling and screening device and its working method

A screening device and technology for seeds, which are applied in the fields of shelling, chemical instruments and methods, and sieving, etc., can solve the problems of large volume, affecting the quality of seeds, damage to the seed coat and endosperm, etc. Efficiency, good germination vigor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

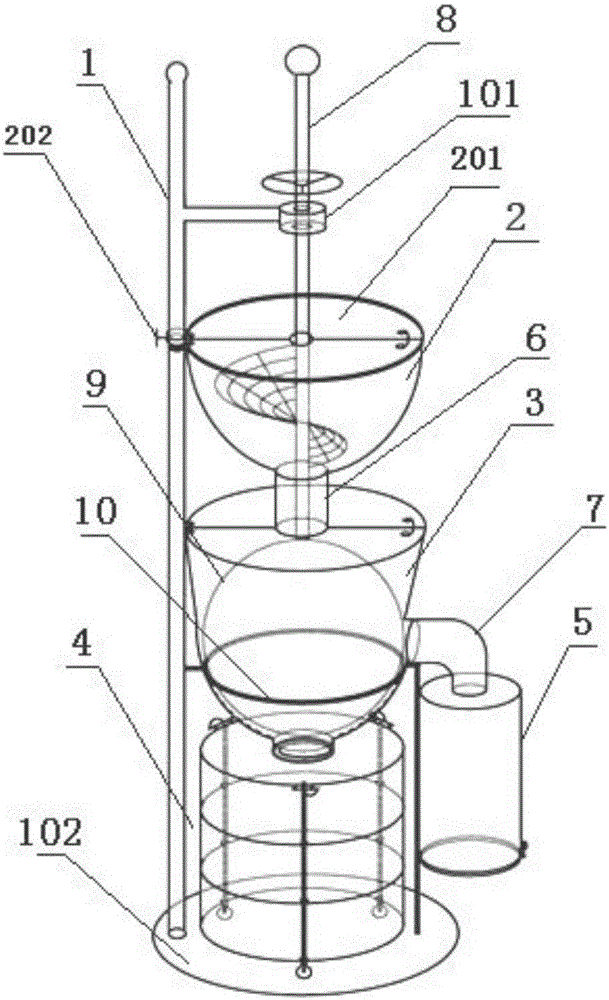

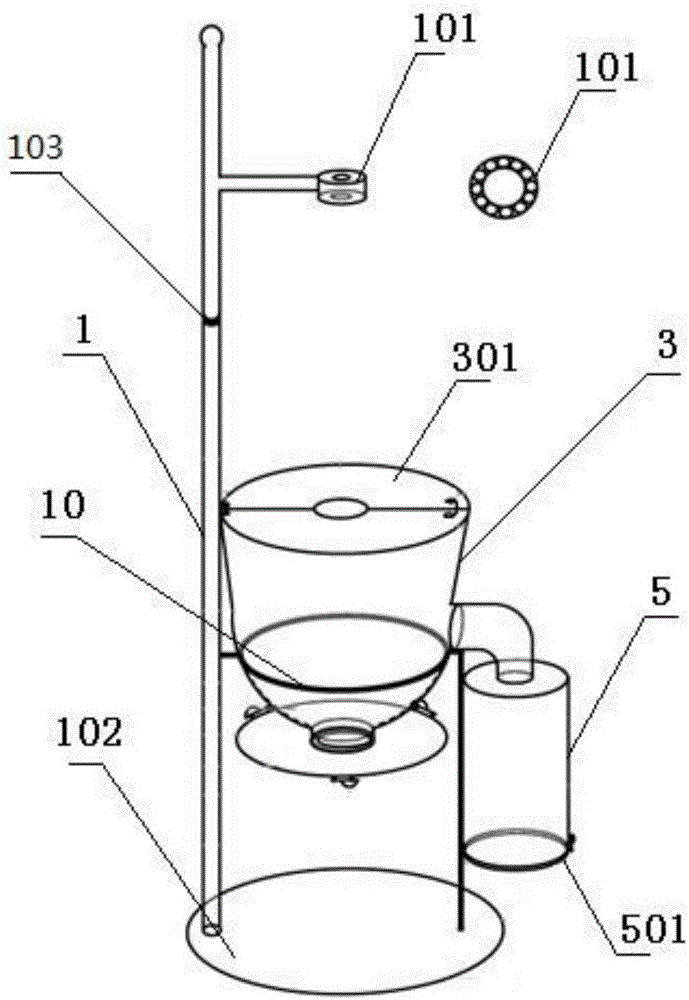

[0072] A seed hulling and screening device provided by the present invention includes a support 1, on which a collecting part 2, a grinding and shelling part 3 and a screening part 4 are fixedly arranged sequentially from top to bottom;

[0073] The collecting part 2, the grinding and shelling part 3 and the screening part 4 are sequentially provided with a material passage for the material to fall vertically along the gravity.

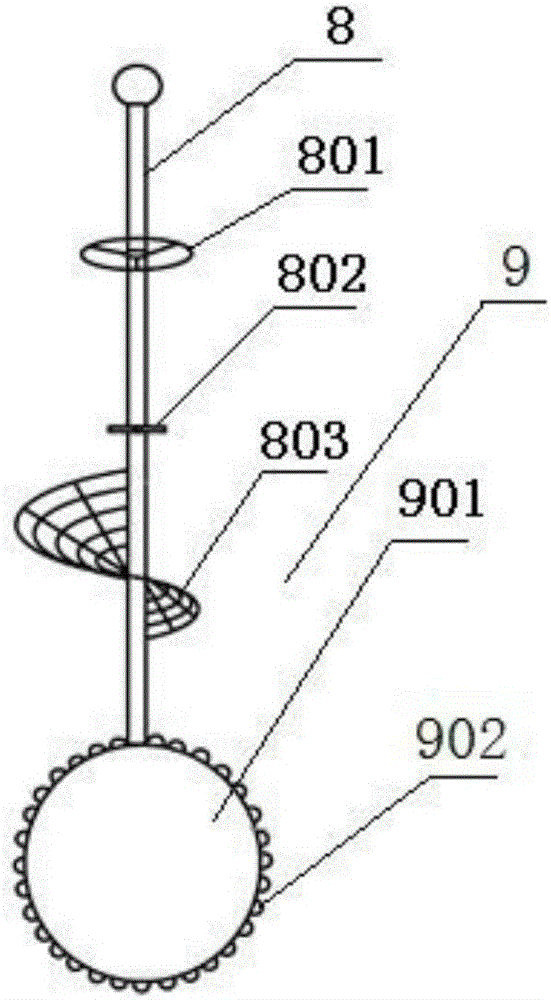

[0074] The device also includes a grinding hammer 9. The grinding hammer includes a grinding rod 8 and a hammer body 901 arranged at the bottom of the grinding rod. The outer surface of the hammer body 901 is adapted to the shape of the bottom of the grinding shell 3; It is arranged on the collecting part 2 and the grinding and shelling part 3 , and the hammer body 901 is accommodated in the grinding and shelling part 3 .

[0075] The device also includes a residue collecting part 5 , which communicates with the lower half of the grinding and shelling...

Embodiment 2

[0087] A kind of seed shelling and screening device provided by the present invention has the structure as described in Example 1, and the difference is that a seed taking port 405 and a sliding sealing piece 406 are arranged on the side of the cylindrical container, and the The sealing sheet 406 is used to open or close the seed taking port 405 . When using this device, seeds can be taken out through the seed taking port 405 on the screen cage 401 and the bottom bucket 410 .

Embodiment 3

[0089] A kind of working method of seed shelling and screening device provided by the invention comprises steps as follows:

[0090] (1) The hammer body 901 of the grinding hammer 9 is completely placed in the grinding and shelling part 3, and the second semicircle combined cover 301 of the grinding and shelling part 3 is closed;

[0091] (2) Adjust the fixed bolt 202 of the collection part 2 to the bolt holder 103 and fix it;

[0092] (3) Open the first semicircle combined cover 201 of the collection part 2, put the shelled seeds into the collection part 2;

[0093] (4) Drive the rotary grinding hammer 9 by driving the grinding rod 8, so that the shelled seeds are clamped between the grinding and shelling part 3 and the grinding hammer 9, and the grinding hammer 9 is rotated at the same time, so that the seeds are shelled and mutually separation;

[0094] (5) Repeatedly drive the grinding hammer 9 so that the seeds ground in step (4) fall into the screening part 4 along the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com