Tobacco flavor for improving taste quality of upper tobacco leaf group

A technology for tobacco essence and cigarettes, which is applied in the direction of essential oils/spices, tobacco, and other applications. It can solve the problems of poor taste, heavy green miscellaneous gas, and high physiological strength, and achieve improved taste quality, increased sweetness, and The effect of reducing the rough feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

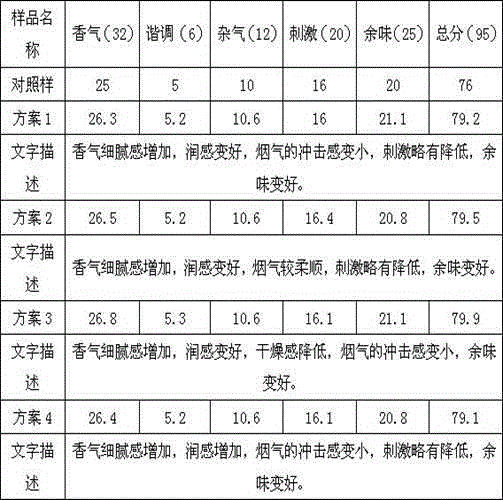

Examples

Embodiment 1

[0027] The tobacco flavor is made by mixing the following raw materials by weight percentage: 0.5% strawberry acid, 3% lactic acid, 2% citric acid, 3% ester angle extract, 10% red date extract, 3% plum extract, vanilla Bean tincture 2%, octyrolactone 0.5%, propylene glycol: 50%, 95% alcohol 26%. After blending evenly, add it to shredded tobacco at a ratio of 0.1%.

Embodiment 2

[0029] The tobacco flavor is made by mixing the following raw materials by weight percentage: strawberry acid 1.5%, lactic acid 4%, citric acid 1.5%, ester angle extract 5%, red date extract 10%, plum extract 5%, vanilla 1% bean tincture, 0.5% octyrolactone, 50% propylene glycol, 21.5% 95% alcohol. After blending evenly, add it to shredded tobacco at a ratio of 0.1%.

Embodiment 3

[0031] The tobacco flavor is made by mixing the following raw materials by weight percentage: strawberry acid 2%, lactic acid 4%, citric acid 1%, ester angle extract 4%, red date extract 10%, plum extract 3%, vanilla 0.5% bean tincture, 1% octyrolactone, 50% propylene glycol, 24.5% 95% alcohol. After blending evenly, add it to shredded tobacco at a ratio of 0.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com