Processing method of ginger processed pinellia

A technology of ginger pinellia and pinellia, applied in the field of processing and processing of Chinese medicinal materials, can solve problems such as unfavorable standardized production, no clear control of processing process parameters, and poor quality stability, so as to reduce the influence of human subjective factors and ensure attenuation Anti-irritant, stable and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of processing method of pinellia ginger, comprises the following steps:

[0024] (1) After decocting 25kg of sliced ginger, add 100kg of net pinellia and soak for 72 hours;

[0025] (2) Add 6kg of alum and continue soaking for 60h, stirring once every 12 hours;

[0026] (3) Take it out, and steam it with a steaming tray, the steaming time is 2 hours, the steaming temperature is 115°C, and the steaming is carried out under the pressure environment of 0.04-0.1mpa to obtain the semi-finished product;

[0027] (4) Cool the semi-finished product obtained in step (3), slice it, and dry it naturally to obtain the finished product A, a total of 89.9kg.

[0028] The yield is: 89.9%. The properties of the finished product A are: flaky, irregular granular or spherical. Surface brown to tan. The texture is hard and brittle, the cross-section is light yellowish brown, often with horny luster. Slightly fragrant gas, light taste, slightly numb tongue feeling, slightly sti...

Embodiment 2

[0030] A kind of processing method of pinellia ginger, comprises the following steps:

[0031] (1) After decocting 25kg of sliced ginger, add 100kg of net pinellia and soak for 96 hours;

[0032] (2) Add 8kg of alum and continue soaking for 72 hours, stirring once every 12 hours;

[0033] (3) Take it out, and steam it with a steaming tray, the steaming time is 3 hours, the steaming temperature is 110°C, and the steaming is carried out under the pressure environment of 0.04-0.1mpa to obtain the semi-finished product;

[0034] (4) Cool the semi-finished product obtained in step (3), slice it, and dry it naturally to obtain the finished product B, a total of 85.3kg.

[0035] The yield is: 85.3%. The properties of the finished product B are: flaky, irregular granular or spherical. Surface brown to tan. The texture is hard and brittle, the cross-section is light yellowish brown, often with horny luster. Slightly fragrant gas, light taste, slightly numb tongue feeling, slightl...

Embodiment 3

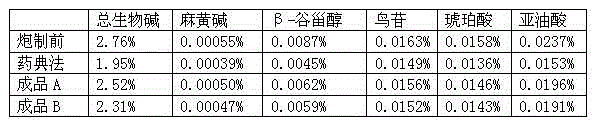

[0037] Comparison of active ingredients before and after processing and pharmacopoeia methods HPLC, TLC and other methods were used to compare the net pinellia before processing ("before processing" in Table 1) and Jiang Pinellia recorded in the 2010 edition of Pharmacopoeia ("pharmacopoeia method" in Table 1) And the common active ingredients in the Pinellia Rhizoma ("finished product A" and "finished product B" in Table 1) that embodiment 1 and 2 obtain measure, measure in parallel 6 times, get average value, and its result is as shown in table 1:

[0038] Table 1 The active ingredients of pinellia before and after processing and different processing methods (the values in the table are all mass percentages)

[0039]

[0040] In addition, the water extracts of finished product A and finished product B are 18% and 16% respectively, while the water extracts of the Pharmacopoeia are 11%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com