Production method of stainless-steel, carbon steel and stainless steel three-layer combined plate coil

A production method and stainless steel technology, applied in workpiece surface treatment equipment, metal processing equipment, metal rolling, etc., can solve problems such as uneven deformation and uneven stress distribution, achieve good surface quality, solve uneven deformation, and become talented high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

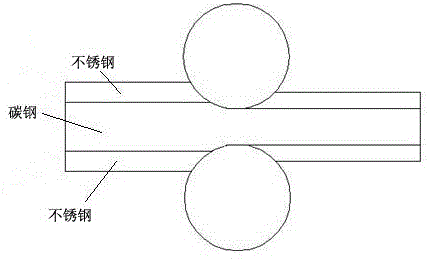

Image

Examples

Embodiment 1

[0027] This embodiment produces a stainless steel-carbon steel-stainless steel three-layer composite coil with a finished product thickness of 3mm.

[0028] Select two stainless steel slabs with a thickness of 20mm and a material of SUS304, and one carbon steel slab with a thickness of 160mm and a material of Q235.

[0029] (1) Assembling slabs: clean the surfaces of stainless steel and carbon steel to be combined, dry them after cleaning, and then stack them in the order of stainless steel-carbon steel-stainless steel. After stacking, the three are welded and fixed. When welding, reserve vent holes in the rolling direction;

[0030] (2) Slab heating: Send the combined stainless steel-carbon steel-stainless steel slab to a heating furnace and heat it to 1240-1260°C for a heating time of 220 minutes; preferably, the combined stainless steel-carbon steel-stainless steel The slab is sent to the heating furnace and heated to 1250°C;

[0031] (3) High-pressure water dephosphoriza...

Embodiment 2

[0036] This embodiment produces a stainless steel-carbon steel-stainless steel three-layer composite coil with a finished product thickness of 8mm.

[0037] Select two stainless steel slabs with a thickness of 20mm and a material of SUS304, and one carbon steel slab with a thickness of 160mm and a material of Q235.

[0038] (1) Assembling slabs: clean the surfaces of stainless steel and carbon steel to be combined, dry them after cleaning, and then stack them in the order of stainless steel-carbon steel-stainless steel. After stacking, the three are welded and fixed. When welding, reserve vent holes in the rolling direction;

[0039] (2) Slab heating: Send the combined stainless steel-carbon steel-stainless steel slab to a heating furnace and heat it to 1220-1240°C for a heating time of 230 minutes; preferably, the combined stainless steel-carbon steel-stainless steel The slab is sent to the heating furnace and heated to 1230°C;

[0040] (3) High-pressure water dephosphoriza...

Embodiment 3

[0045] This embodiment produces stainless steel-carbon steel-stainless steel three-layer composite coils with a finished product thickness of 12 mm.

[0046] Select two stainless steel slabs with a thickness of 20mm and a material of SUS304, and one carbon steel slab with a thickness of 160mm and a material of Q235.

[0047] (1) Assembling slabs: clean the surfaces of stainless steel and carbon steel to be combined, dry them after cleaning, and then stack them in the order of stainless steel-carbon steel-stainless steel. After stacking, the three are welded and fixed. When welding, a vent hole should be reserved in the rolling direction;

[0048] (2) Slab heating: Send the combined stainless steel-carbon steel-stainless steel slab to a heating furnace and heat it to 1220-1240°C for a heating time of 240 minutes; preferably, the combined stainless steel-carbon steel-stainless steel The slab is sent to the heating furnace and heated to 1230°C;

[0049] (3) High-pressure water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com