Method for establishing large floating type wind power station tower drum

A construction method and tower technology, applied in the field of electric power equipment, can solve the problems of serious occupation of production sites, difficult control of welding quality, multiple hoisting, etc., so as to improve welding efficiency and welding quality, reduce the probability of accidents, reduce The effect of construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

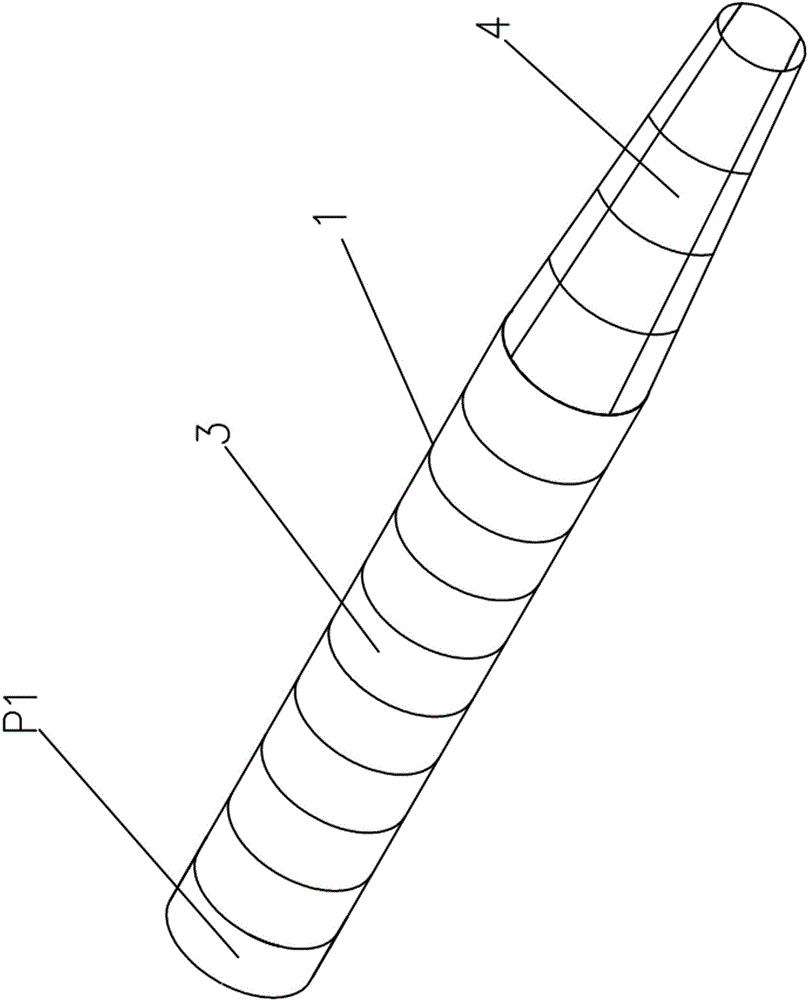

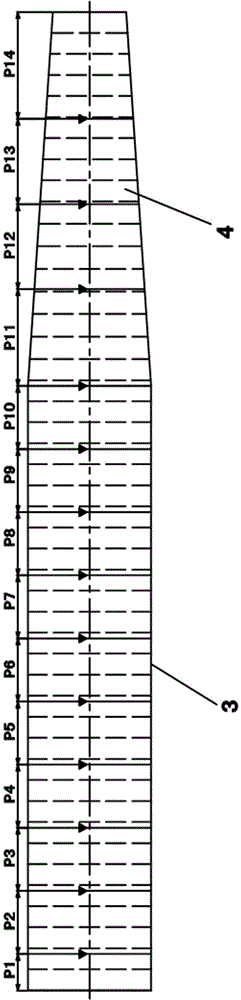

[0060] Below in conjunction with accompanying drawing, the present invention will be further described, and the maximum diameter of the tower tube of this embodiment reaches 12m, and the total height of the tower tube is 98m.

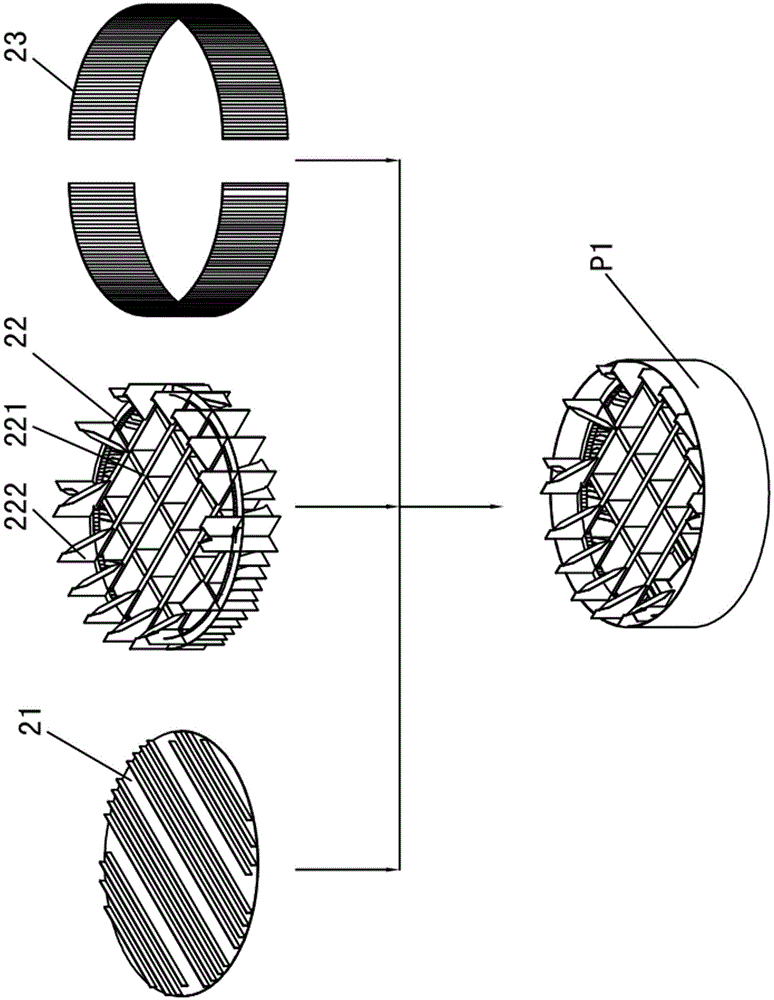

[0061] like figure 1 , figure 2 As shown, the tower tube 1 includes the bottom tube section P1, the middle tube section 3, and the top tube section 4. The tower tube 1 is sequentially welded by the above three parts, and the middle tube section 3 is composed of nine identical middle tube sections P2 -P10 is welded in sequence, and the top cylinder section 4 is formed by sequentially connecting four identical top cylinder sections P11-P14;

[0062] like image 3 As shown, the construction method of tower tube 1 comprises the following steps:

[0063] 1) Steel plate surface pretreatment: firstly, conduct quality investigation on the steel plate used for manufacturing, determine the degree of corrosion on the steel plate surface, and then pass shot bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com