Press-fit mechanism for valve guide

A valve guide, press-fitting technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of high labor intensity of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

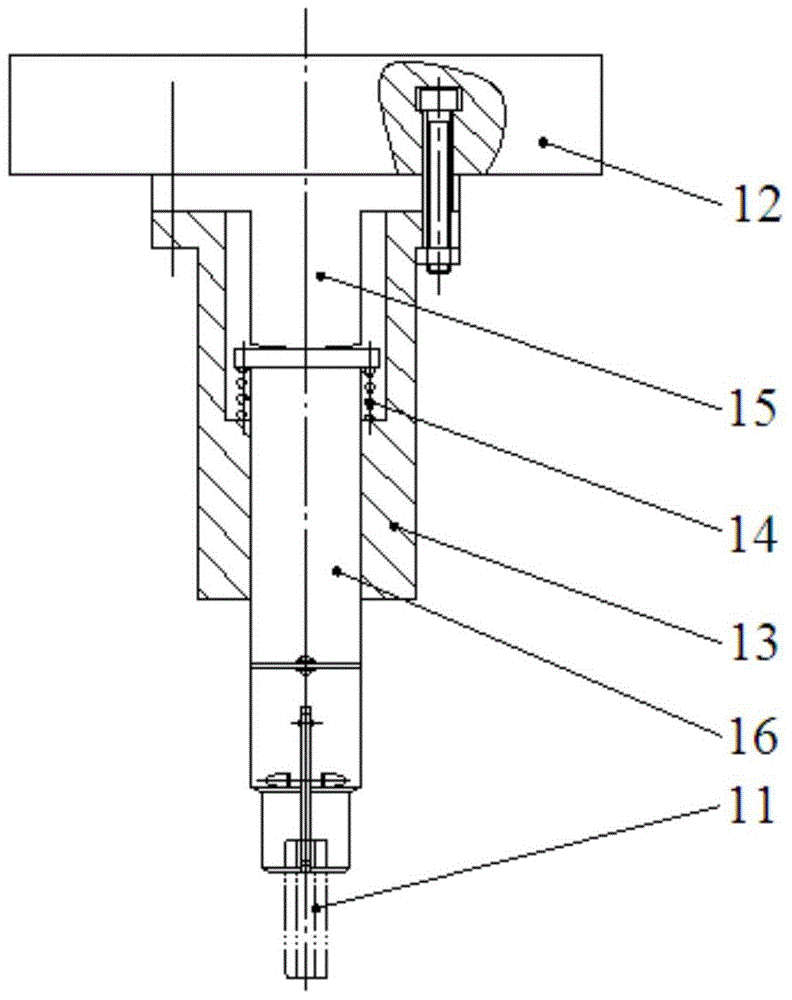

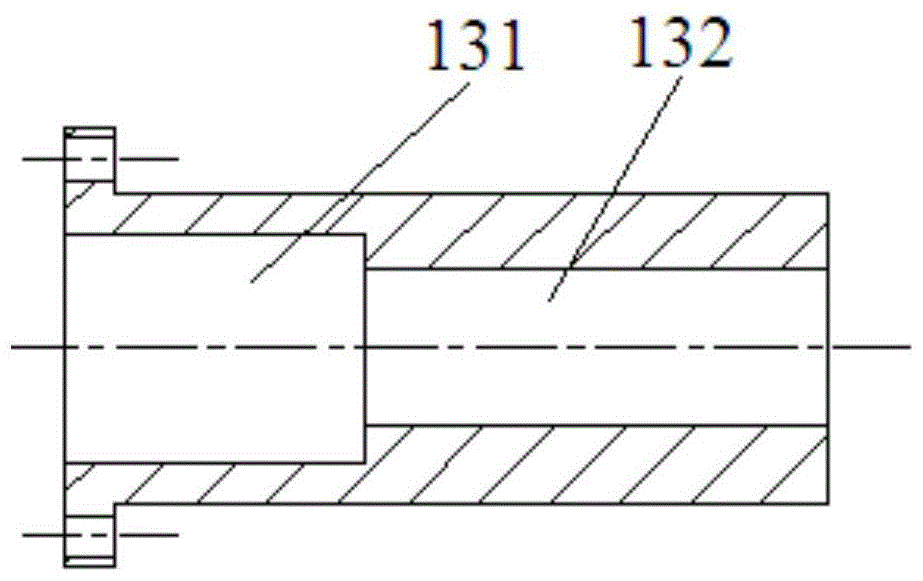

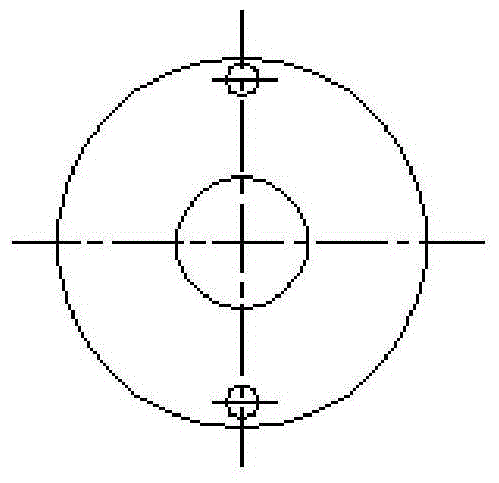

[0029] Such as Figure 1-8 As shown, the embodiment of the present invention provides a valve guide press-fitting mechanism, which is used to press the valve guide 11 into the guide bottom hole on the cylinder head, including a power source providing driving force and a pressing plate fixed to the power source 12 and a pressure head detachably connected to the pressure plate 12, the end of the pressure head is provided with a conduit accommodation hole for accommodating the valve conduit 11.

[0030] The above-mentioned power source can be a hydraulic press, the pressure head can be a solid rod-shaped piece, and the end of the pipe can be provided with a conduit accommodation hole. When the press-fitting mechanism works, the valve guide 11 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com