Rotary disc mechanism in cabinet adjusting leg full-automatic assembly system

A technology of assembly system and turntable mechanism, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of single specification of processing parts, poor versatility, and high cost of turntable, and achieve flexible use, avoid waste, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

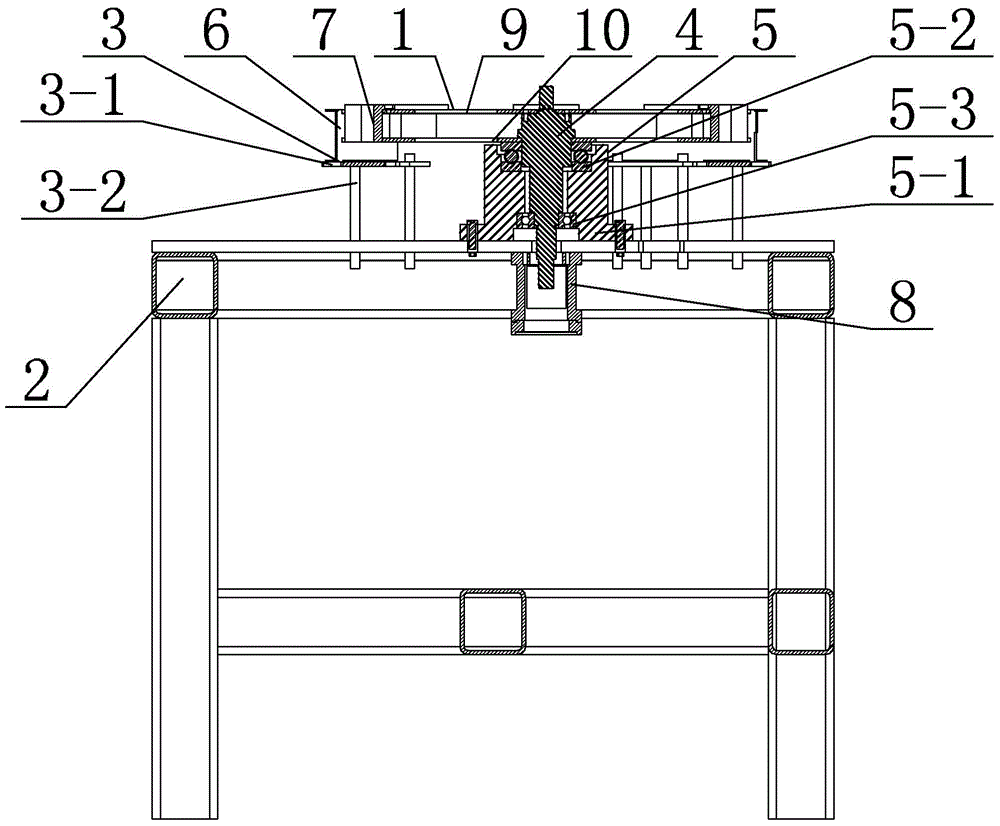

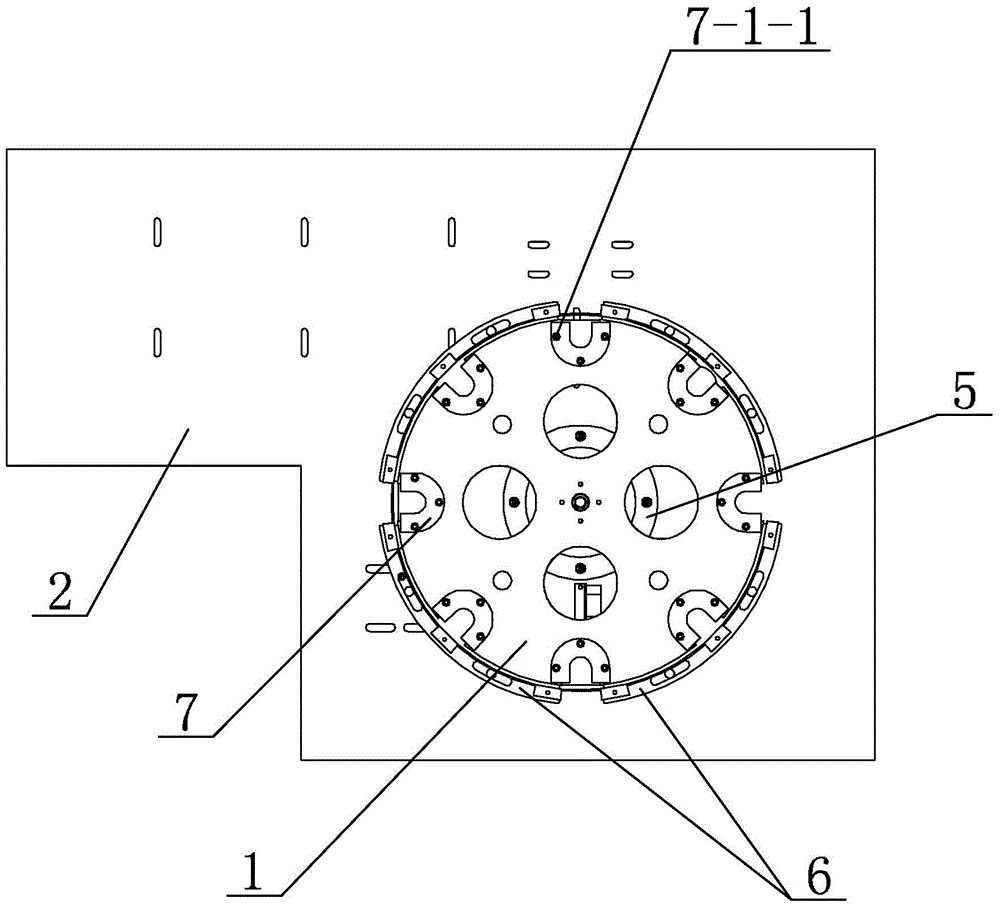

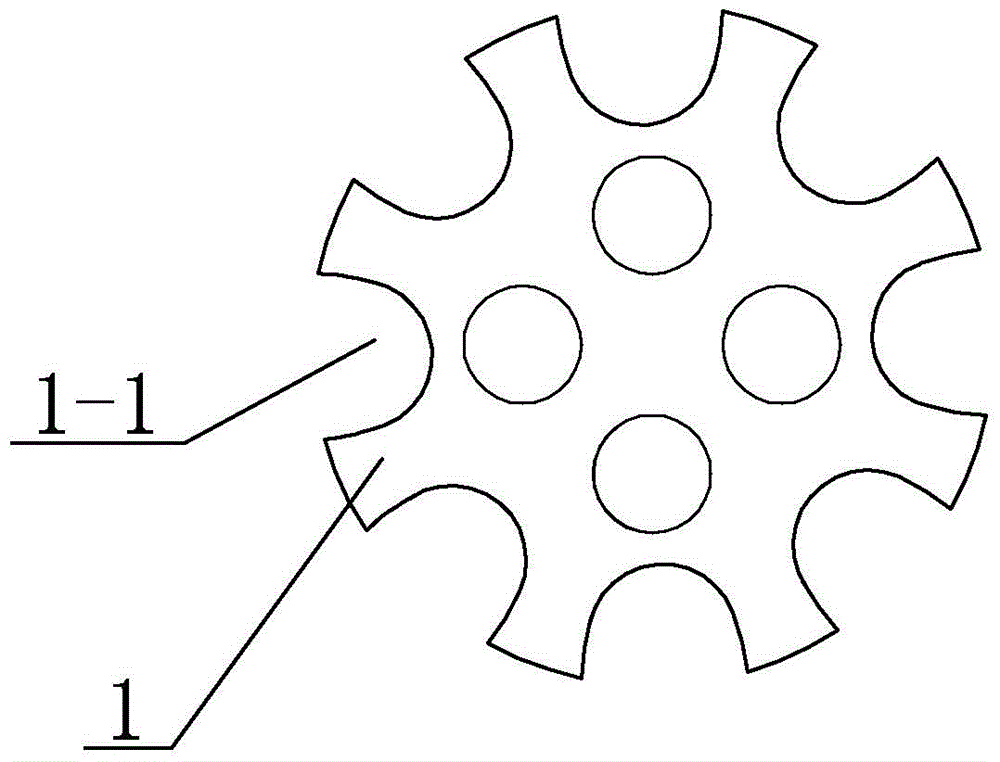

[0012] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Describe this embodiment, the turntable mechanism in the fully automatic assembly system for cabinet adjustment feet described in this embodiment includes a turntable body 1, a turntable platform 2, a pallet frame 3, a turntable spindle 4, a bearing assembly 5, and a plurality of stoppers Arc line body 6 and a plurality of U-shaped molds 7, the turntable platform 2 is placed horizontally, the turntable body 1 is arranged above the turntable platform 2, and a pallet frame 3 is arranged directly below the turntable body 1, and The plate frame 3 is a hollow circular frame body and is fixedly connected on the turntable platform 2. The edge of the upper end surface of the pallet frame 3 is evenly distributed with a plurality of material retaining arc lines 6, and each material retaining arc line body 6 is closely attached to the edge of the turntable body 1, and the hollow...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination Figure 4 and Figure 5 Describe this embodiment. In this embodiment, the horseshoe-shaped plate 7-1 is processed with a plurality of installation holes 7-1-1, and the U-shaped mold 7 is detachably connected to the The U-shaped notch 1-1 of the turntable body 1. A plurality of installation holes 7-1-1 are through holes for screws, and the arrangement of the plurality of installation holes 7-1-1 is to detachably connect the horseshoe-shaped plate 7-1 to the turntable body 1 by screws, so that the U-shaped mold The disassembly between 7 and the turntable body 1 is convenient, and the screws are cheap in cost, which helps to reduce the manufacturing cost of the present invention. Components not mentioned in this embodiment are the same in structure and connection relationship as in Embodiment 1.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 2 To illustrate this embodiment, the turntable mechanism in the fully automatic assembly system for cabinet adjustment feet described in this embodiment also includes a motor base 8, which is fixedly connected to the lower end surface of the turntable platform 2, and the motor base 8 A stepper motor is arranged on it, and the bearing assembly 5 includes a bearing seat 5-1, a booster bearing 5-2 and a rolling bearing 5-3, and the bearing seat 5-1 is arranged between the turntable body 1 and the turntable platform 2, so that A vertical channel is processed inside the bearing seat 5-1, and the power-assisted bearing 5-2 and the rolling bearing 5-3 are sequentially arranged in the vertical channel from top to bottom, and the turntable main shaft 4 passes through the turntable from top to bottom The body 1, the booster bearing 5-2, the rolling bearing 5-3 and the turntable platform 2 are connected with the output shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com