Assembling and clamping device for tube sheet processing

A clamping device and tube sheet technology, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of low processing efficiency and low processing accuracy, and achieve improved processing efficiency, good versatility, and alignment. effect of time reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

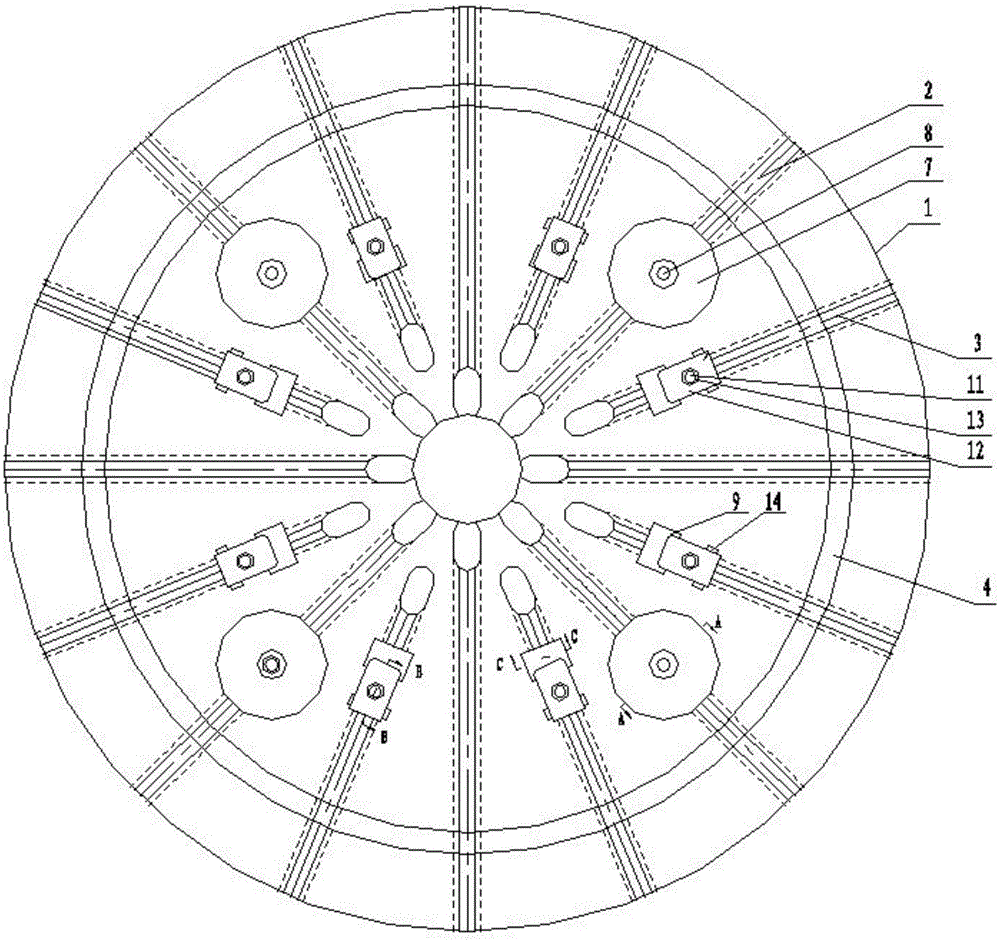

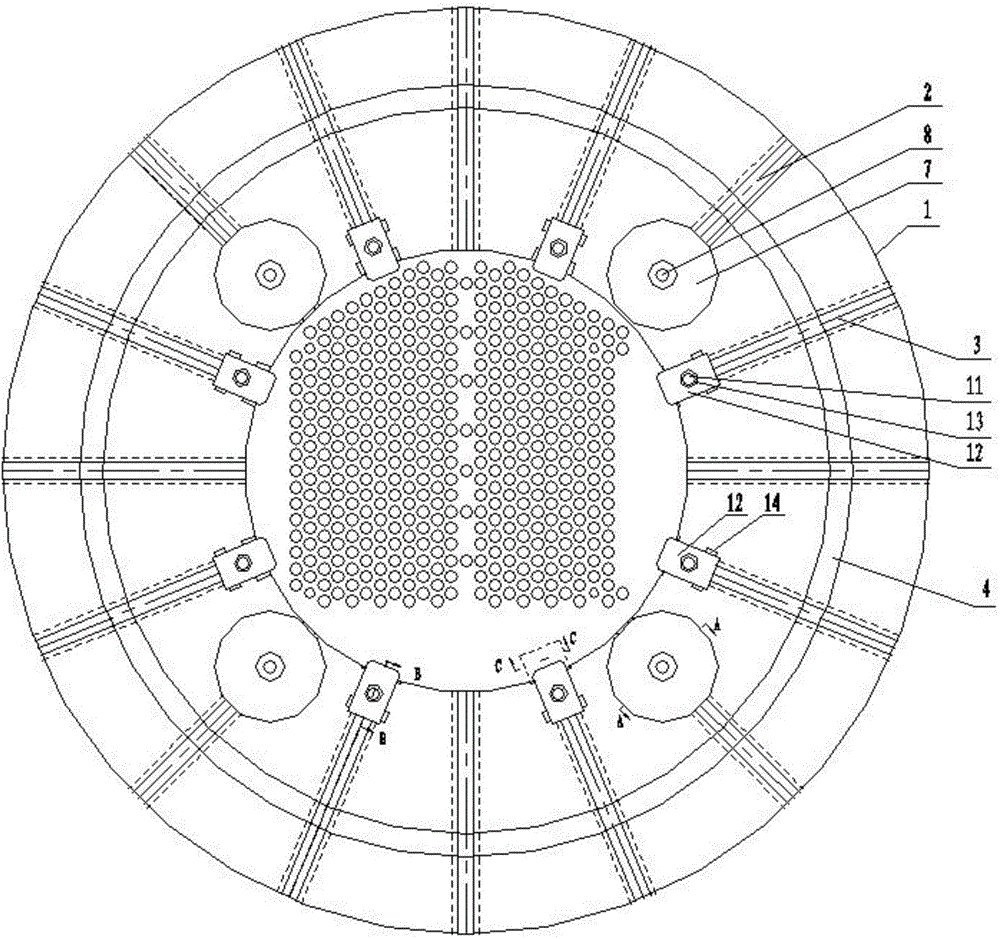

[0015] The clamping device for tube sheet processing in this embodiment, such as figure 1 , 3 , 4, and 5, its composition includes: disc table 1, a group of T-shaped grooves A (part number 2 in the figure) and a group of T-shaped grooves are arranged on the radial direction of the upper surface of the disk table 1 B (item number 3 in the figure), T-shaped groove A (item number 2 in the figure) and T-shaped groove B (item number 3 in the figure) are evenly arranged in the circumferential direction of the disc table 1, The upper surface of the disc workbench 1 is provided with a circular groove 4 in the circumferential direction on the side close to the outer edge;

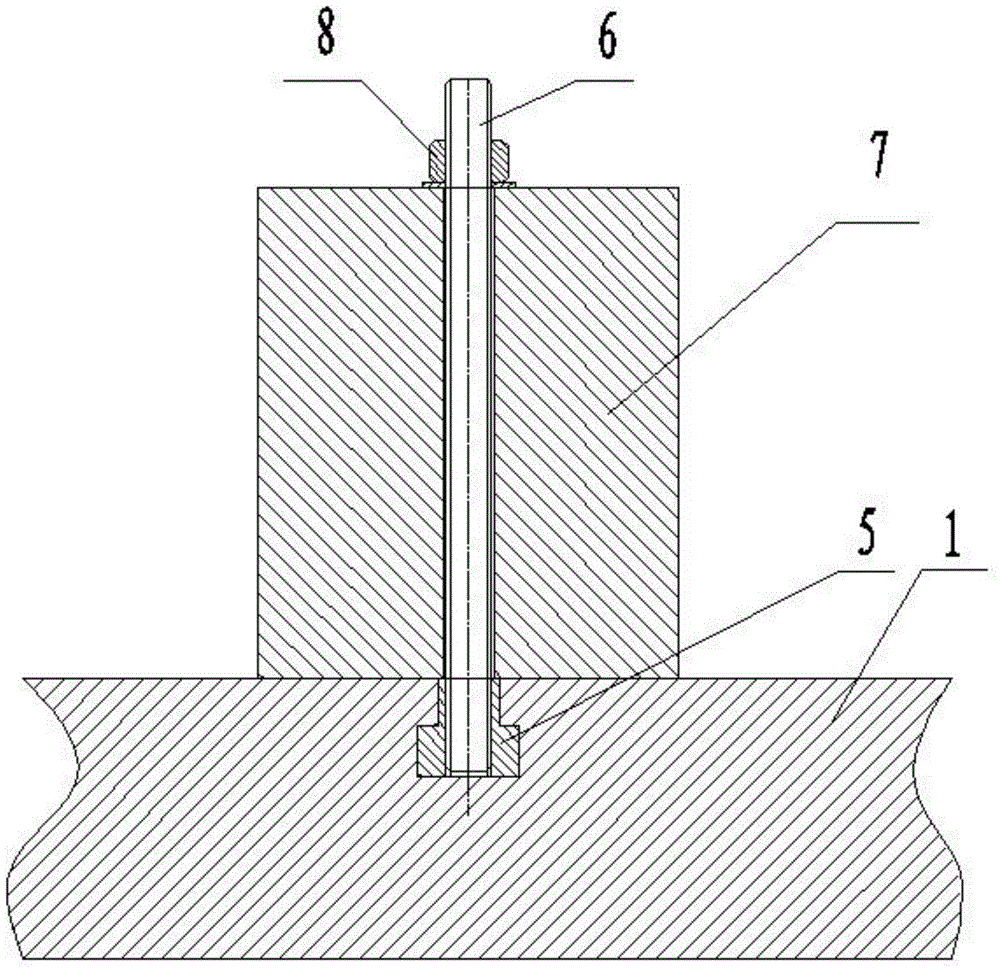

[0016] Among them, the sliding block A (the item number is 5 in the figure) is slidably installed in the T-shaped groove A (the item number is 2 in the figure), and the top of the slider A (the item number is 5 in the figure) is screwed to the double-ended screw A (the item number is shown in the figure). The part...

specific Embodiment approach 2

[0018] The difference from Embodiment 1 is that the clamping device for tube sheet processing in this embodiment, such as figure 1 , 3 , Shown in 4 and 5, the protrusion at the bottom of the equal height sliding pad 9 is located in the T-shaped groove A (the part number is 2 among the figures).

specific Embodiment approach 3

[0019] Different from the first or second specific embodiment, the clamping device for tube sheet processing in this embodiment, such as figure 1 , 3 , 4, and 5, the height of the slider A (the item number is 5 in the figure) is the same as the depth of the T-shaped groove A (the item number is 2 in the figure), and the slider A (the item number is 5 in the figure) The two opposite side surfaces and bottom surfaces with shoulders are in sliding contact with the two inner sidewalls and bottom surfaces of the T-shaped groove A (item number 2 in the figure).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com