High-performance sleeve tool

A high-performance, sleeve technology, applied in the direction of manufacturing tools, wrenches, screwdrivers, etc., can solve the problems of short service life, sleeve wear, and reduce work efficiency, so as to expand the scope of application, prolong the service life, and improve the use efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

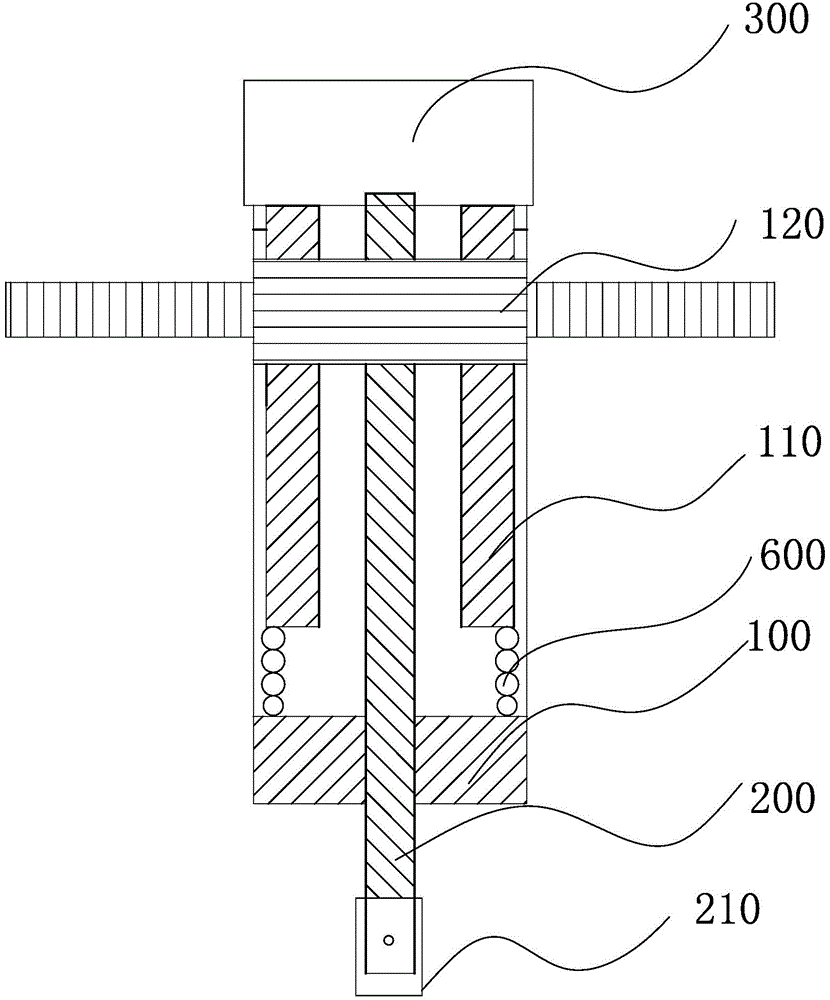

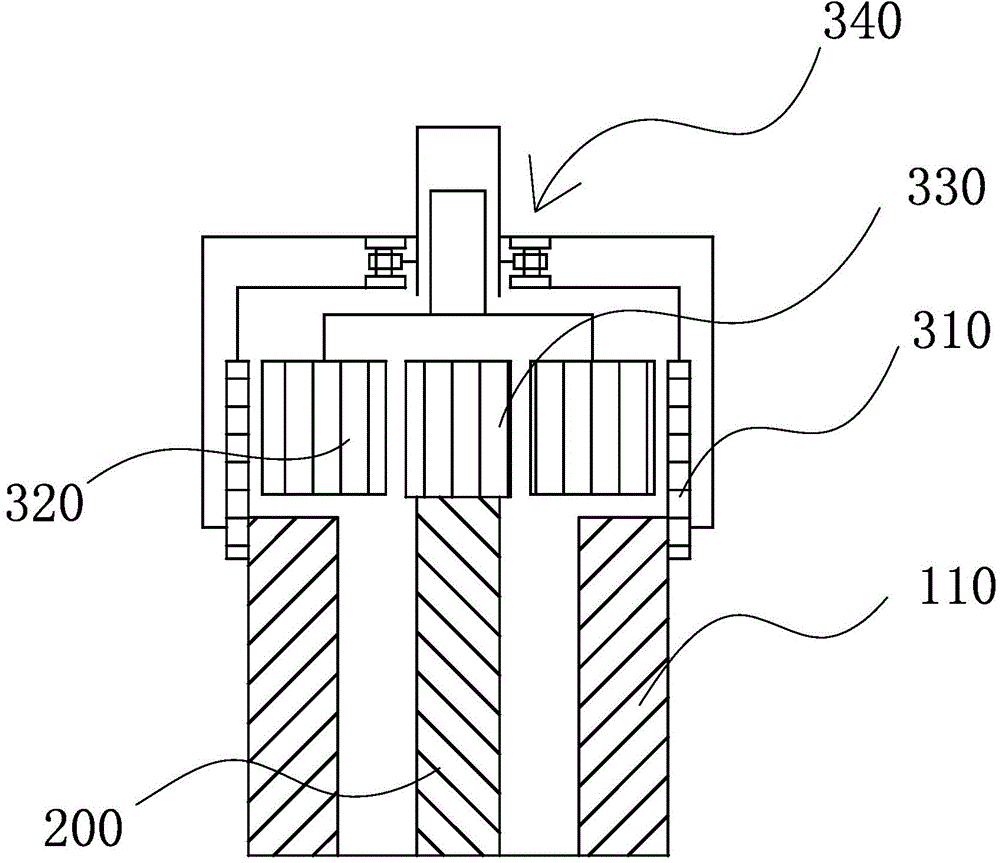

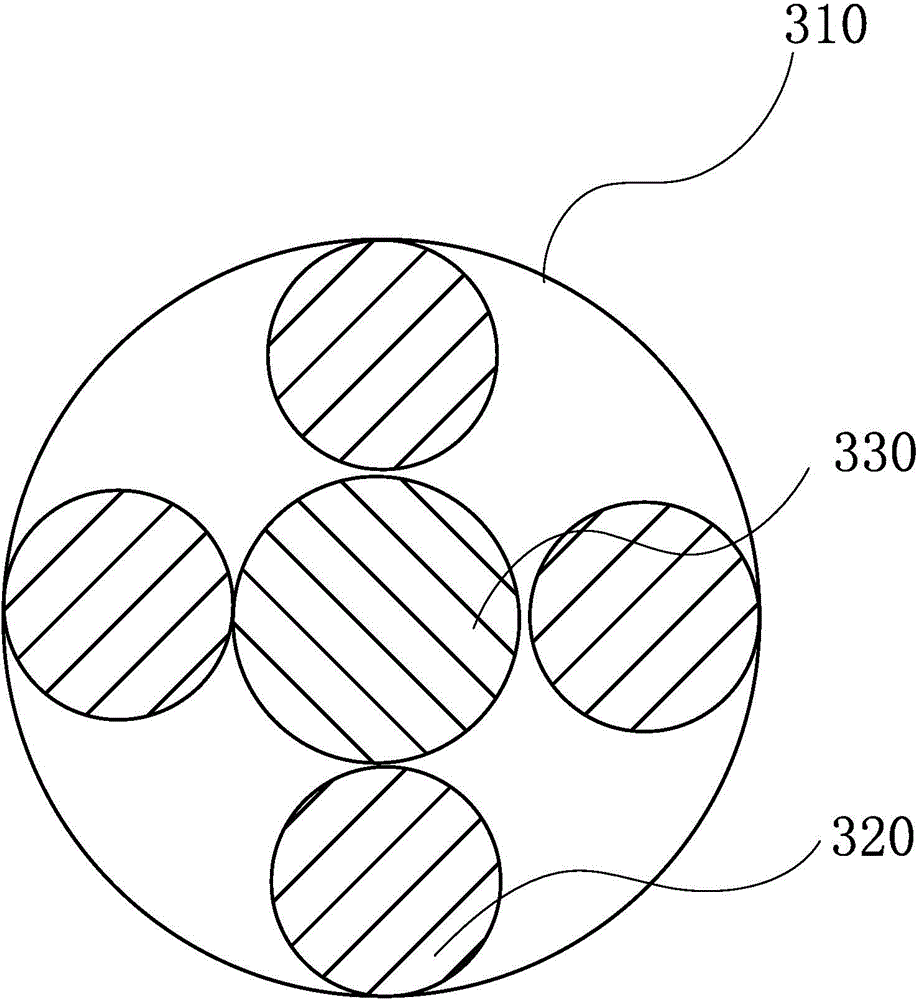

[0045] Embodiment 1: The above-mentioned transmission device 300 includes a ring gear 310 connected to the sleeve 110, a sun gear 330 arranged in the middle of the ring gear 310 and connected to the main shaft 200, and a plurality of planetary gears 320 uniformly surrounding the sun gear 330 , the planetary gear 320 is engaged with both the ring gear 310 and the sun gear 330 respectively, and the diameter of the sun gear 330 is equal to that of the planetary gear 320, and the diameters of both are smaller than the diameter of the ring gear 310. Preferably, the planetary gear The number of wheels 320 is 4, but the number of planetary gears 320 is not limited to 4. The planetary gears 320 are evenly arranged around the sun gear 330 and the angle between adjacent planetary gears 320 is 90 degrees. The setting of the wheel 320 ensures the stability of the transmission between the planetary gear 320 and the ring gear 310 and between the planetary gear 320 and the sun gear 330. Compa...

Embodiment 2

[0049] Embodiment 2: The above-mentioned transmission device 300 includes a driving gear 400 connected to the sleeve 110, a driven gear 410 arranged parallel to and coaxial with the driving gear 400, and a plurality of driving gears 400 and 410 arranged between Transmission gear 420, the number of transmission gears 420 is preferably two, but not limited to two, so that the driving gear 400 drives the transmission gear 420 to rotate in the same direction, and makes the driven gear 410 to rotate in the opposite direction, and the main shaft 200 runs through the driving gear in turn 400 and the driven gear 410 protrude outward from the outer surface of the driven gear 410 and a connector 430 is provided at the protruding end, and a plugging block 440 is also provided on the main shaft 200, and the plugging block 440 is arranged on the driving gear 400 Between the driven gear 410 and the driven gear 410, the connecting head 430 can drive the main shaft 200 to slide in the vertical...

Embodiment 3

[0067] Weigh the raw material according to the composition and mass percentage of the above-mentioned sleeve, crush and refine the raw material into metal powder, and roll it into a sleeve blank under a pressure of 450MPa; the sleeve material is mainly composed of the following chemical components in weight percentage: C: 0.35%, Si: 0.40%, Mn: 0.85%, Cr: 1.20%, Ni: 0.20%, Cu: 0.30%, Ti: 0.08%, V: 0.20%, the balance is Fe and other unavoidable impurities ;

[0068] Anneal the above-mentioned sleeve blank at 680°C, and then carry out rough machining, quenching and tempering finishing;

[0069] The processed sleeve blank is subjected to rough grinding, fine grinding, polishing, tumbling, oiling, and etching to remove the oxide layer to obtain a semi-finished sleeve;

[0070] Plating bright chrome on the semi-finished sleeve after the above treatment, the electroplating solution for bright chrome plating contains chromic anhydride 135g / L, sulfuric acid 2.0g / L, and the current den...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com