A steel bar tightening device for construction

A steel bar and tightening technology, which is applied in the field of steel bar tightening equipment, can solve the problems of not being able to meet the needs of different diameters of steel bar binding and tightening, the limited adjustment of the binding gear, and the increase in the cost of iron wire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] see Figure 1-6 , the present invention provides a specific embodiment of a steel bar tightening device used in construction;

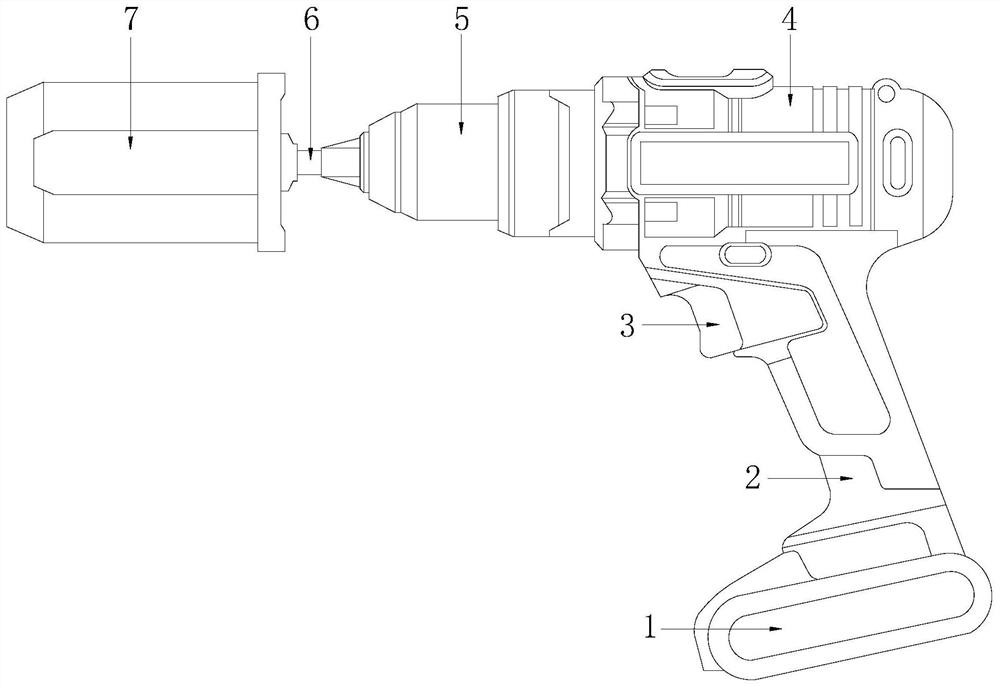

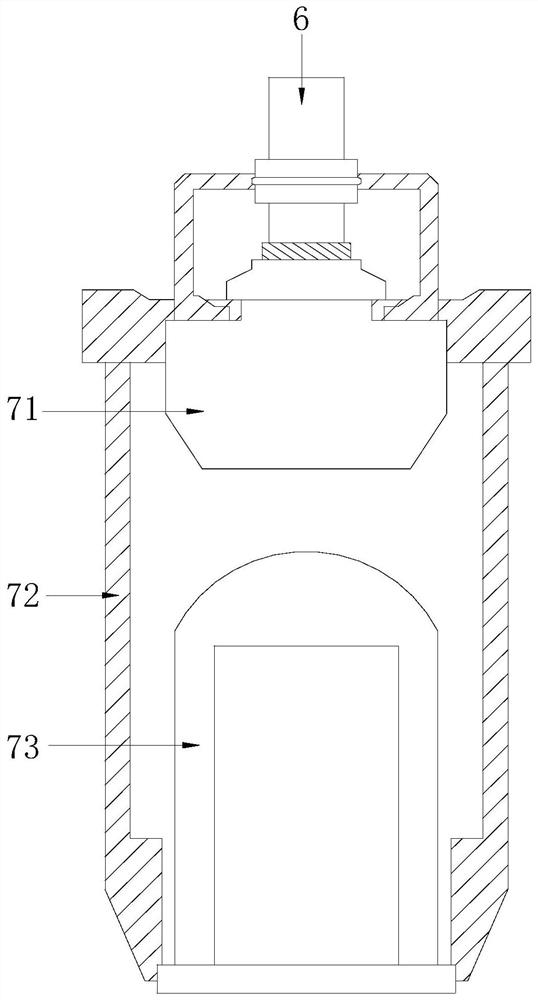

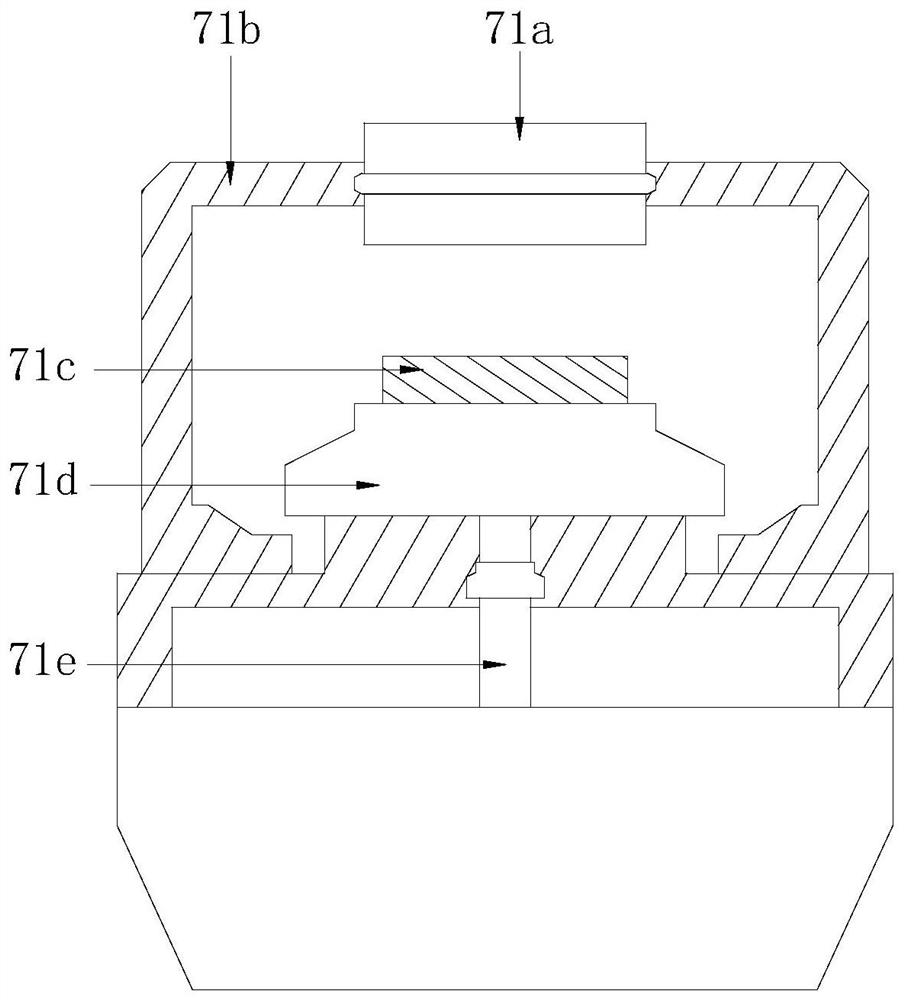

[0025] see figure 1 , a steel bar tightening device used in construction, its structure includes a battery 1, a handle 2, a start button 3, an electric drill drive body 4, a coupling 5, a transmission shaft 6, and a wire binding device 7. The electric drill drives The bottom of the fuselage 4 is provided with a handle 2, the front end of the handle 2 is provided with a start button 3, and the bottom end of the handle 2 is provided with a battery 1, and the battery 1 is electrically connected to the electric drill drive body 4, and the The battery 1 and the handle 2 are movably connected, and the center position of the front end of the electric drill driving body 4 is provided with a coupling 5, and the coupling 5 and the electric drill driving body 4 are transmission connected, and the coupling The central position of the front end of 5 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com