Intelligent glass suction cup

A technology of smart glass and suction cups, which is applied to conveyor objects, furnaces, lighting and heating equipment, etc., can solve the problems of personnel safety hazards, slipping, and easy slipping, and achieve the effect of safe handling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

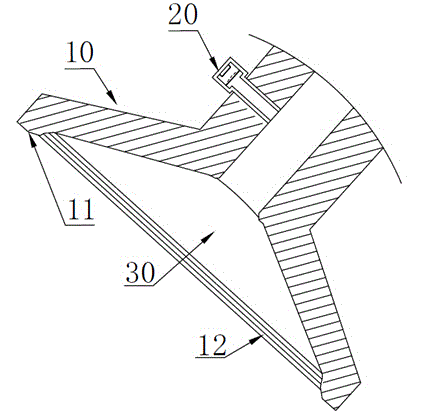

[0014] Examples, see figure 1 Shown: the smart glass suction cup, including the suction nozzle 11 with the glass contact surface, the suction cup 12 for forming negative pressure and the negative pressure chamber 30 for maintaining the adsorption force, it is characterized in that, the negative pressure chamber is equipped with Negative pressure sensor 20 for detecting suction force.

[0015] When working, the sensor 20 senses the pressure change in the negative pressure cavity 30. When the pressure reaches the set value, it means that the adsorption force reaches the weight of lifting the glass or its products, and it can be transported safely.

[0016] The inside of the pressure sensor is a diffused silicon pressure sensitive chip, which makes it more sensitive and smaller deviation, which further ensures the safety and reliability of the glass suction cup handling.

[0017] The above descriptions are only preferred embodiments of the present invention, and are not intended...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com