A bead punching seat structure of a bead nailing machine

A technology of bead flushing seat and bead nailing machine, which is applied in the decoration of textiles, textiles and papermaking, etc. It can solve the problems of high processing and installation costs, generation of defective products, mixed beads with small diameters, etc., and save processing and installation costs , low processing and installation costs, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

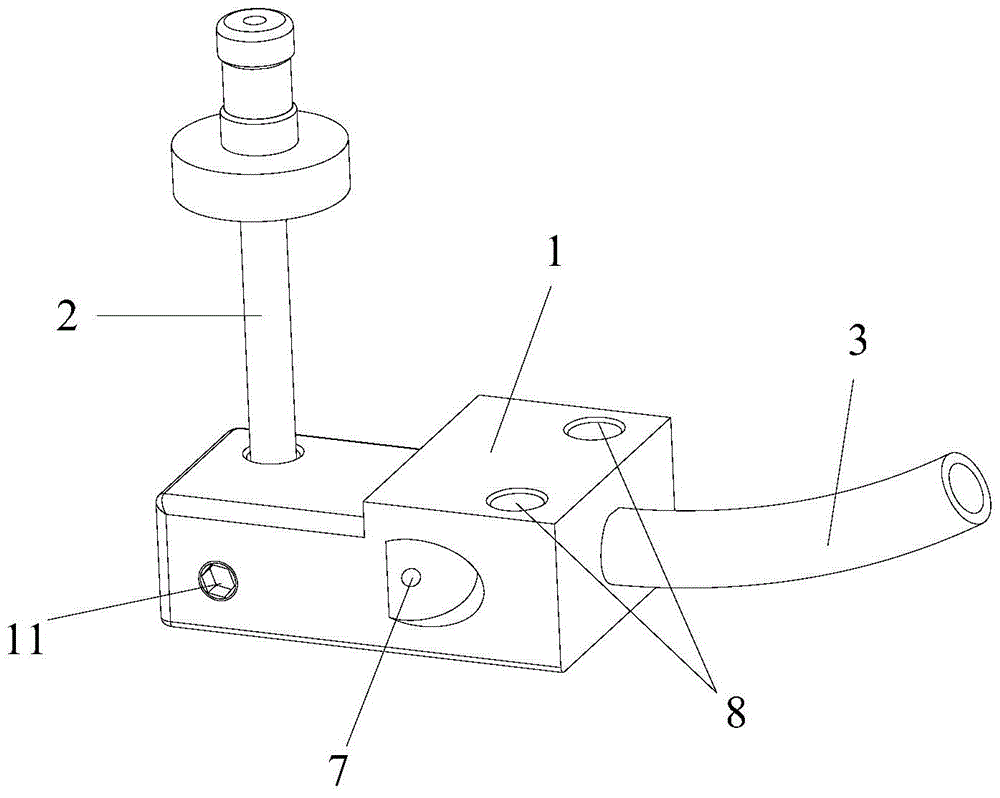

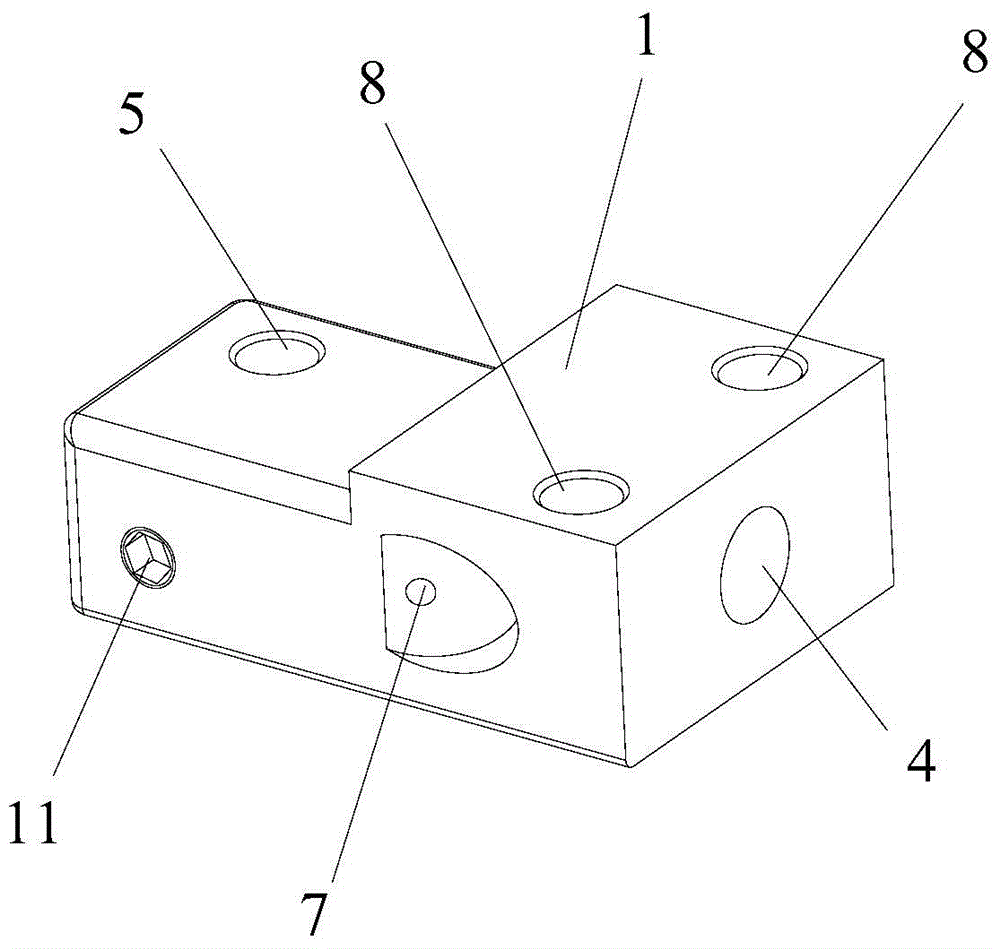

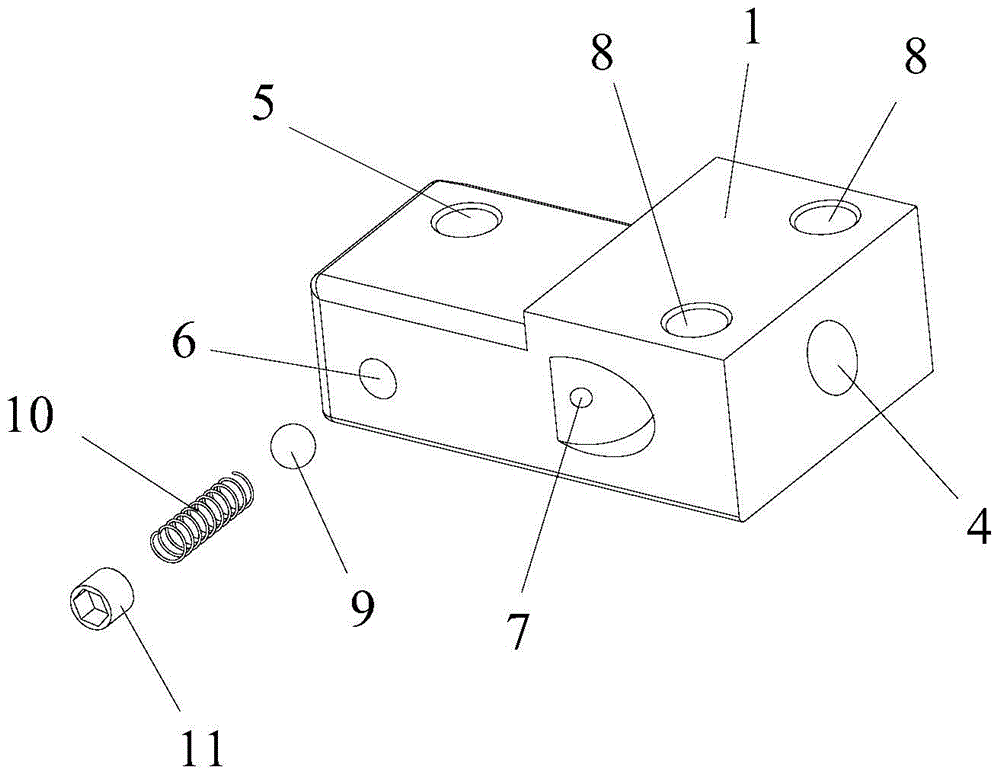

[0043] See Figure 1-Figure 6 , figure 1 It is the overall structure diagram of the bead punching seat structure of the bead nailing machine in Embodiment 1 of the present invention, and the bead channel and punching rod are also included in the figure; figure 2 It is the overall structural diagram of the structure of the beading seat of the bead nailing machine in Embodiment 1 of the present invention; image 3 It is an exploded structure diagram of the structure of the beading seat of the bead nailing machine in Embodiment 1 of the present invention; Figure 4 It is a top view structure diagram of the structure of the bead punching seat of the bead nailing machine in Embodiment 1 of the present invention; Figure 5 for Figure 4 The cross-sectional structure diagram of A-A direction in the middle; Image 6 for Figure 4 The cross-sectional structure diagram of the B-B direction in the middle.

[0044] The bead punching seat structure of the bead nailing machine provid...

Embodiment 2

[0062] The bead punching seat structure of the bead nailing machine provided by the embodiment of the present invention includes a seat body, and a bead inlet hole and a punching hole provided on the seat body.

[0063] The entrance of the bead hole is set on the outer wall of the seat body, the outlet of the bead hole is set on the inner wall of the punching hole, the bead hole is connected with the bead channel, the beads enter from the entrance of the bead hole, and the bead hole is connected to the outlet of the bead hole After coming out, it enters the punching hole. The punching hole vertically passes through the upper and lower surfaces of the seat body, and the punching rod moves up and down in the punching hole to punch down the beads and nail them together with the button.

[0064] The seat body is also provided with a pressing hole, and the outlet of the pressing hole is arranged on the inner hole wall of the punching hole. There are balls, springs and locking piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com