A self-controlled rubber dam with wear-resistant steel plates

A rubber dam and steel plate technology, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems of abrasive damage and low cost, and achieve high bearing capacity and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

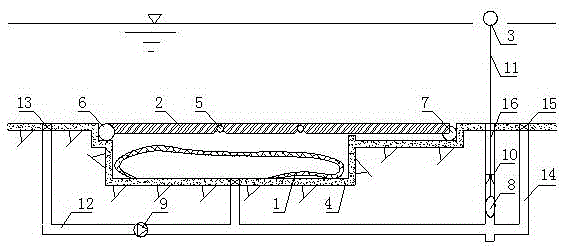

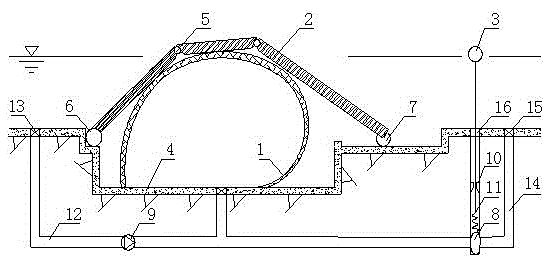

[0014] like figure 1 As shown, the self-control rubber dam with wear-resistant steel plates provided by the present invention includes a reinforced concrete groove 4 arranged in the river channel, a rubber dam 1 anchored on the bottom plate of the groove, and a dam from the upstream side to the downstream in the riverbed below the groove. The water supply and drainage pipeline on the side, the water supply and drainage pipeline includes the water inlet section 12 on the upstream side and the water outlet section 14 on the downstream side, and the water supply and drainage pipeline communicates with the inside of the rubber dam in the groove at the same time; a Wear-resistant steel plate 2 with hinged support, said wear-resistant steel plate is formed by connecting two or three joints (three joints in this example) through one-way rotating steel hinge 5, and the setting of one-way rotating steel hinge 5 can make the steel hinge place resist The grinding steel plate can only be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com