Pipeline robot with garbage smashing and collecting function

A pipeline robot and garbage crushing technology, which is applied in the direction of cleaning sewer pipes, waterway systems, water supply devices, etc., can solve problems such as poor safety, low degree of automation, and endangering workers' lives, and achieve the effect of convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

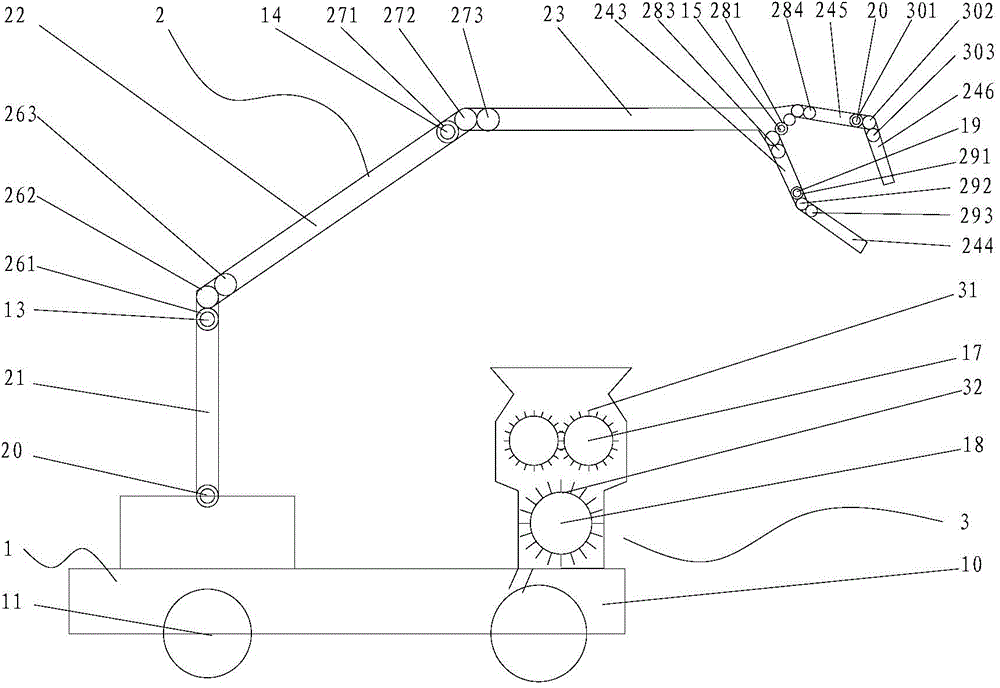

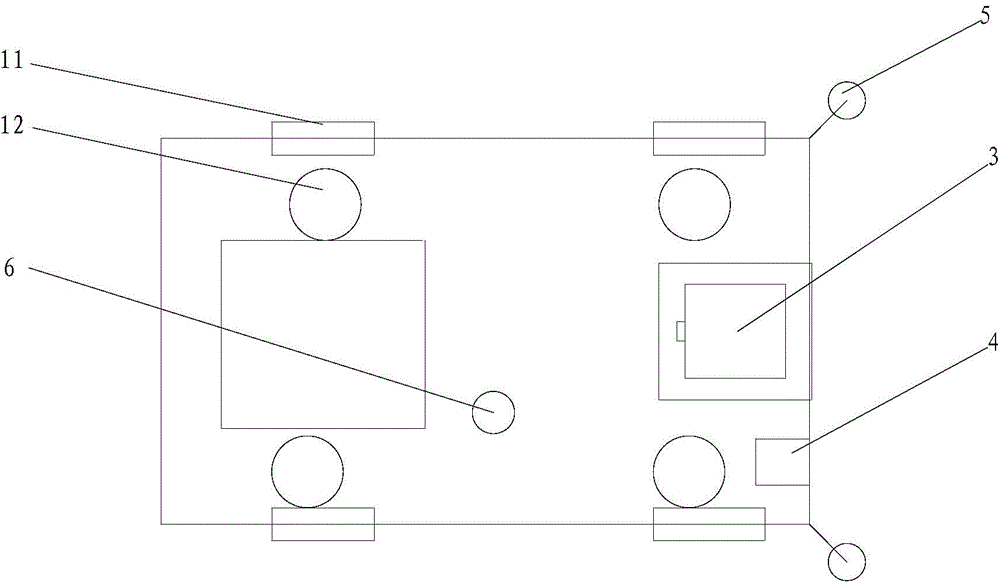

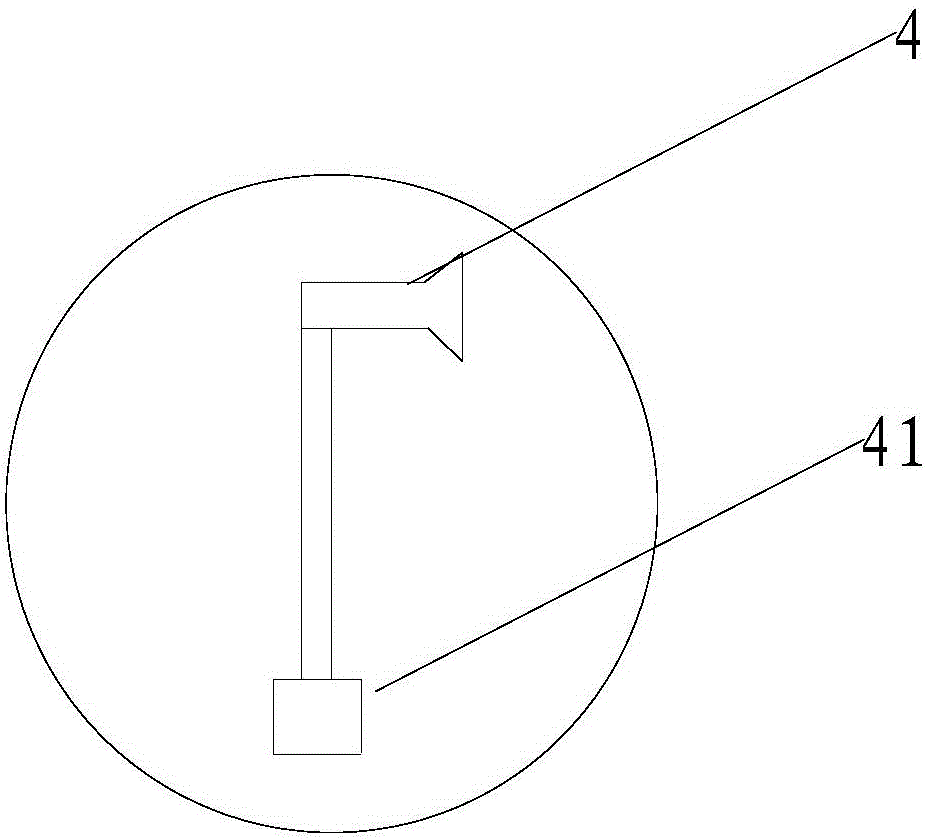

[0024] like Figure 1-3 As shown in one of them, the present invention includes a wheeled power vehicle 1, a mechanical arm 2, a pulverizer 3 and a main controller (not shown in the figure), the mechanical arm 2 is set at the rear end of the wheeled power vehicle 1, and the pulverizer 3 is set At the front end of the wheeled power vehicle 1, the outlet of the pulverizer 3 communicates with the garbage receiving chamber 10 provided in the wheeled power vehicle 1, and the wheeled power vehicle 1, the mechanical arm 2 and the pulverizer 3 are respectively electrically connected to the main controller;

[0025] Described wheeled power vehicle comprises four wheels 11, and each described wheel is driven by a wheel stepper motor 12;

[0026] Described mechanical arm comprises first joint arm 21, second joint arm 22, third joint arm 23, finger arm 24, joint wrist gear set and more than two transmission gear sets, and described transmission gear set comprises driving wheel, follower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com