Passive locking device for urban rail train door system

An urban rail and locking device technology, applied in door/window fittings, wing leaf operating mechanisms, buildings, etc., can solve the problems of low reliability, high cost, complex structure, etc., and achieve high reliability and low production cost. , the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

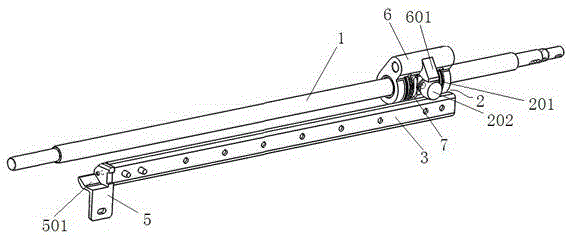

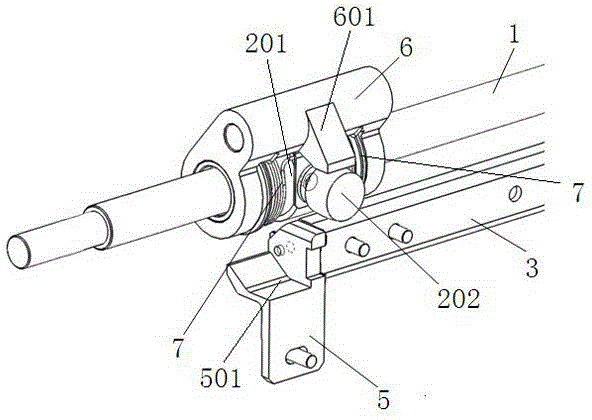

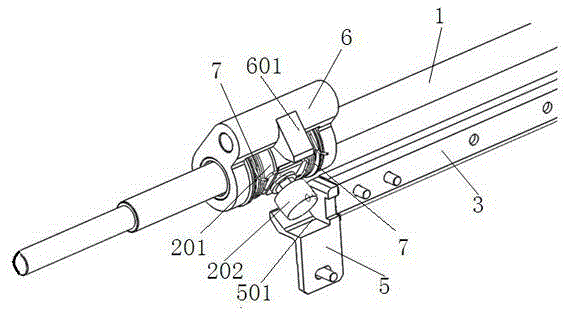

[0019] like Figure 1 to Figure 4 As shown, a passive locking device for urban rail train door system, including screw rod 1, nut pin assembly 2, support slideway 3, position adjustment gasket 4, locking block 5, transmission fork assembly 6 and torsion spring 7, the screw rod 1 is installed on the base of the door system carrying the drive mechanism, the nut pin assembly 2 includes a nut 201 sleeved on the screw rod 1, a rolling pin 202 fixed on the outer wall of the nut 201 , the screw transmission pair is formed between the nut 201 and the screw mandrel 1, the nut 201 is a plastic nut, which has a certain buffering effect with the screw mandrel 1, and the use is delayed. Moreover, the plastic nut of the present invention has a high degree of firmness and will not Easy to break, the rolling pin 202 keeps in contact with the support slideway 3 located on the side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com