Dual-system two-hardness short-wall coal seam mining method

A short-wall, shearer technology, applied in surface mining, earth-moving drilling, underground mining, etc., can solve the problems of slow mining speed of working face, affecting the replacement of overlying coal seam mining, low production efficiency, etc. The effect of sustainable development, improving coal recovery rate and accelerating mining speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

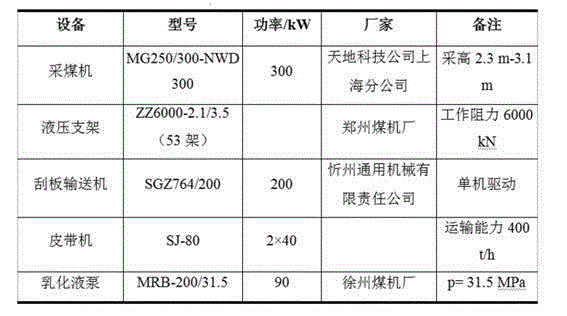

Image

Examples

Embodiment Construction

[0017] Taking Sitai Mine of Tongmei Group as an example, the technical solution claimed in the present invention is further clearly and completely explained.

[0018] Sitai Mine is a super large underground mine with an annual design production capacity of 5 million tons. Since it was completed and put into operation on December 13, 1991, the output of the mine has increased year by year. In 2004, the output of the mine reached 4.8 million tons.

[0019] Sitai Minefield is located in the north of Datong Coalfield, with a length of about 13 km from north to south, and a length of about 7.5 km from east to west, with an area of 82.5 km2; the main coal seams mined are 10#, 11#, 12#, and 14#. The geological structure in the minefield is complex. There are currently 5 production panels in the whole mine, namely 307, 402, 404, 303, and 410 panels.

[0020] Sitai Mine is a mine with very complex geological structure and serious damage to small kilns. With the increase of mining li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com