A method for reducing emission of exhaust gas retained in diesel engine Miller cycle

A Miller cycle, diesel engine technology, applied in the direction of machines/engines, electrical control, mechanical equipment, etc., can solve the problems of poor NOx generation control effect, good emission reduction effect, high charge temperature, etc., to improve the high temperature environment in the cylinder , Weaken NOx generation, reduce the effect of in-cylinder temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

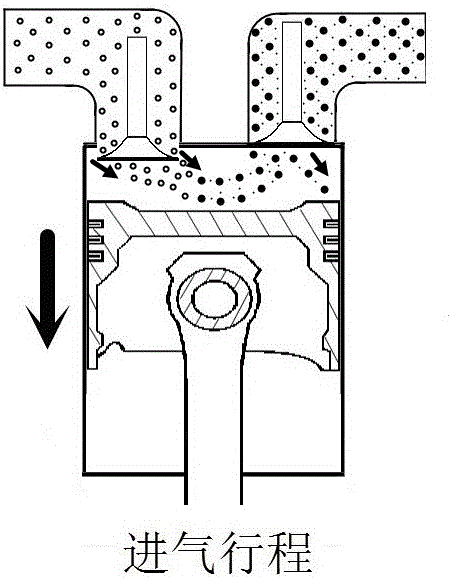

[0035] The core of the present invention is to redesign the intake and exhaust phases of the target model, so as to realize the implantation of exhaust gas recirculation technology retained in the engine into the working process of the Miller cycle of the diesel engine, and to perform combustion optimization. Describe in detail below in conjunction with accompanying drawing and example. This embodiment proposes specific structures and usage conditions, but this embodiment cannot be used to limit the present invention, and all similar methods and similar changes of the present invention should be included in the protection scope of the present invention.

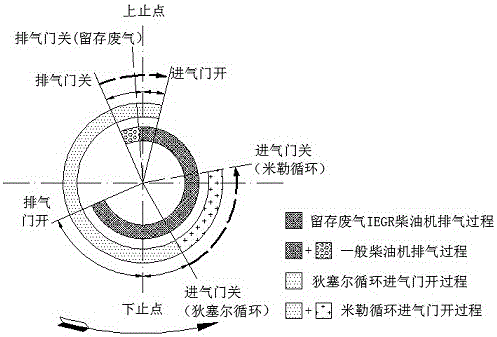

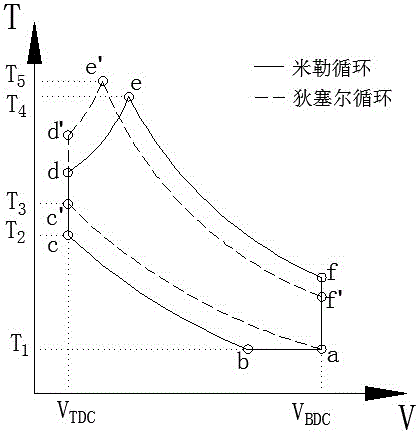

[0036] The gas distribution phase diagram of the present invention is as follows figure 1 As shown, in this way, the exhaust gas recirculation technology retained in the engine can be implanted into the working process of the Miller cycle of the diesel engine.

[0037] The Miller cycle is a thermodynamic cycle form of an int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com